8.

The system should be charged with the correct amount of refrigerant.

9.

The oil should be warmed up above minimum start up oil temperature (see

"Product Information").

10.

The control cabinet should be energised to check the package controls.

Hint!

Do not forget to charge the oil separator (if present) initially with oil, to

the level of the float assembly

1.2.1

Moving instructions and storage

For loose component or compressor package weights, refer either to the relevant

component type plate or package lay-out or to the suppliers document. For bare

compressor weights, see "Product Information".

Caution!

Every precaution must be taken while moving the package to its final

location. Pushing, pulling or climbing on any package component or

piping, can easily create damage.

1.2.2

Storage

The compressor (package) is filled with dry nitrogen. Keep the system closed

until the package is installed. If the compressor (package) is stored, it should be

kept at all times in a dry location to prevent corrosion damage. If the compressor

(package) is to be stored for a prolonged period of time, it should be checked

weekly to ensure that the holding charge of dry nitrogen remains above

atmospheric pressure.

1.2.3

Hoisting and moving instructions

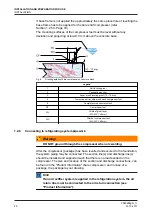

Fig.2:

Hoisting a compressor package

INSTALLATION AND PREPARATION FOR USE

INSTALLATION

0089288gbr_11

14

30.10.2017

Содержание Grasso V 1100

Страница 6: ...0089288gbr_11 6 30 10 2017 ...

Страница 8: ...0089288gbr_11 8 30 10 2017 ...

Страница 10: ...0089288gbr_11 10 30 10 2017 ...

Страница 61: ...Fig 16 Grasso V 6 Pre lubrication valve APPENDIX Product Information PI 0089288gbr_11 30 10 2017 61 ...