3.6.1

Compressor

General remarks about check list;

1.

Check list for compressor only; all other components have to be maintained

according to their specific manuals (IMM and SIM).

2.

All items of the list below marked “check“, have to be checked visually and

checked for proper working.

3.

Some components have to be measured.

For measuring details refer to SIM.

4.

Measuring means also that visual inspection is required.

5.

Visual inspections:

The visual inspections during maintenance are of importance; measurements

should be carried out at the moment that visually abnormalities are detected.

The result of the inspection determines whether one or more parts have to be

replaced. For more detailed information refer (SIM) and Installation and

Maintenance Manual (IMM).

6.

Oil and oil return systems:

The quality of the oil effects the oil consumption and the life time of the

moving parts. For oil return systems or systems in which soluble oil is being

used, we advise to check (or have checked) the quality of the oil every 5000

hours and - if necessary - to renew the oil and/or filters. If there is no oil

analysis available, we advise to renew the oil. By regularly carrying out oil

analyses and registering them in a log, aberrations will be noticed in an early

stage, which may prevent or reduce resultant damage(s).

Note 1:

When renewing the oil, in the crankcase the oil in the oil separator and the oil

return or oil rectifier system (if fitted) has to be renewed.

Note 2:

Pre-lubricate the compressor before re-starting. Used or filtered oil should

NEVER be added to a compressor under any circumstance. Use only new oil

as selected from the Grasso oil table. Oil charging via the suction line of the

compressor is not allowed.

Grasso Maintenance Monitor (GMM) is applied

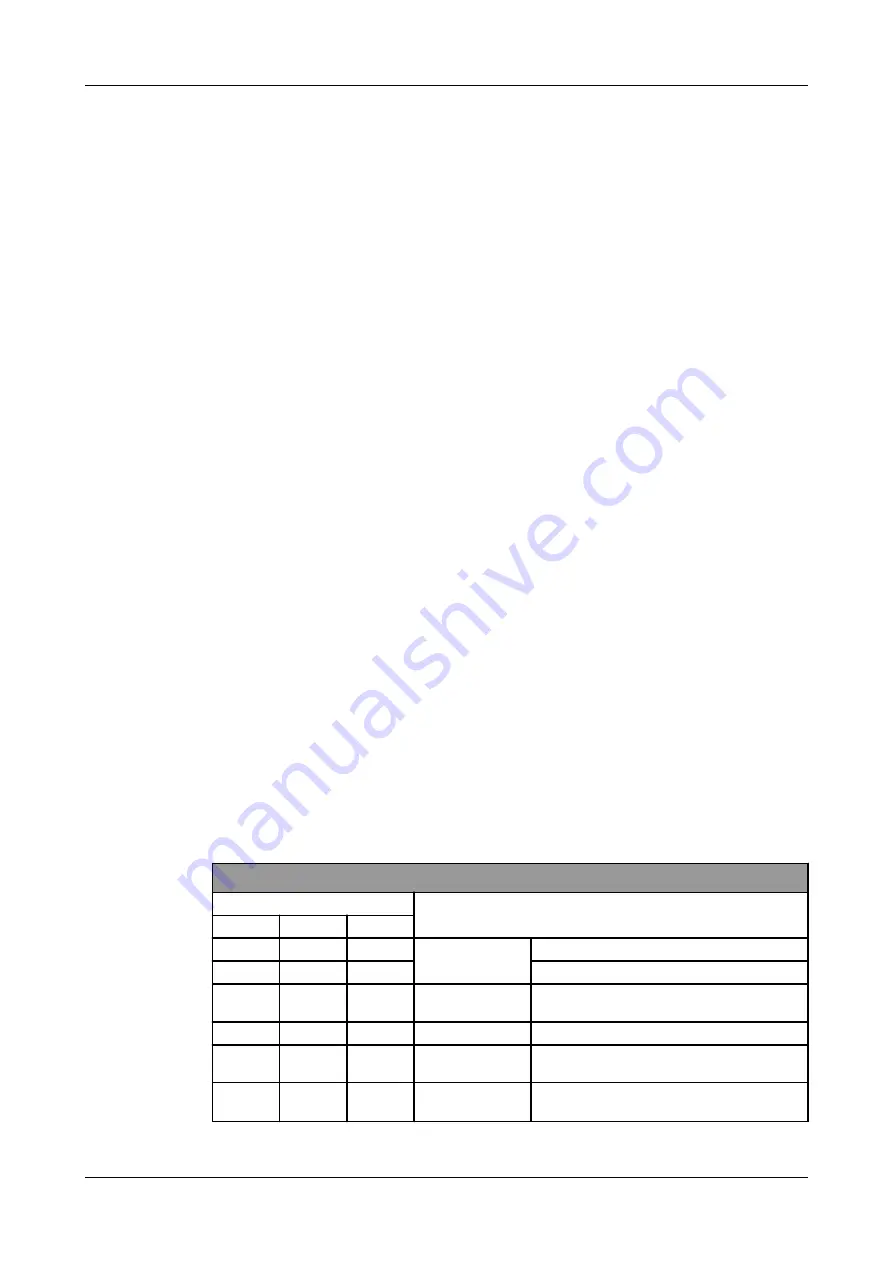

Maintenance compressor

Description

A

B

C

Check

Check

Check

Capacity control

Solenoid valve and coils

Check

Replace

Seals of cap control piston / lifting mechanism

Check

Check

Check

Compressor

housing

Oil return orifice (LP and) HP

Check

Check

Check

Crankcase heater

Measure

Crankshaft

Main (and intermediate) bearings, running

surface

Visual

inspection

Connecting rod

Cylinder located nearest to the shaft-end of the

compressor:

MAINTENANCE

Description Maintenance ABC when GMM is applied

0089288gbr_11

30.10.2017

43

Содержание Grasso V 1100

Страница 6: ...0089288gbr_11 6 30 10 2017 ...

Страница 8: ...0089288gbr_11 8 30 10 2017 ...

Страница 10: ...0089288gbr_11 10 30 10 2017 ...

Страница 61: ...Fig 16 Grasso V 6 Pre lubrication valve APPENDIX Product Information PI 0089288gbr_11 30 10 2017 61 ...