GEI-50299 Power Circuit Breakers Types AK-2 -15

and

AK-2/3-25

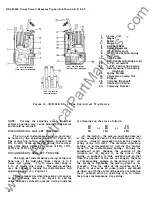

1.

Series Coil

2 .

Magnet

3.

Pallet

4 .

Pinion

5.

Escape Wheel

6.

D riving Segment

7.

S. T .D. Armature

8.

S. T .D. Calibration Spring

9.

Trip Arm

10.

Trip Paddle

1 1.

Trip Paddle Adjusting Screw

12.

L.T

.D .

Armature

LEFT SIDE VIEW SHOWING

SHORT TIME DELAY MECHANISM

RIGHT SIDE VIEW SHOWING

LONG TIME DELAY MECHANISM

13.

L.T

.D.

Calibration Spring

14.

Instantaneous Trip Spring

FRONT VIEW SHOWING

MOUNTING BRACKET

(High Set)

1 5.

Spring Holder

1 6.

Calibration Clamp Nut

1 7.

Plunger

18.

Cylinder (Dashpot)

1 9.

Calibration Plate

20.

Clamping B racket

Figure 12. (695C189) E C - 1 Type Overcurrent Trip Device

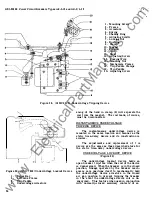

NOTE :

Forcing the adjusting screw to either

extreme position may cause binding of the device

and should be avoided.

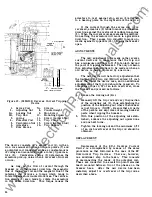

INSTANTANEOUS LOW-SET TRIPPING

The low-set instantaneous pick-up point may

be varied by the adjustment knob (5), Figure 10.

The calibration in this case usually ranges from

BOo/a

to 2 50% of the series coil rating, the calibra

tion plate being indexed at values of 80%,

l OOo/0,

2 00% and 250% of the rating.

INS TANTANEOUS HIGH-SET TRIPPING

The high set instantaneous pick-up value may

have one of the following three ranges: 4 to 9

times coil rating;

6 to 12 times coil rating or

9 to 15 times coil rating. The pick-up setting

may be varied by turning the instantaneous trip

adjusting screw (4), Figure 1 1 .

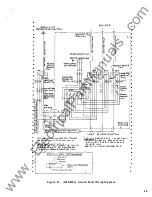

Three standard calibration marks will appear

on the operating arm at (9), Figure 1 1 , and the

value of these calibration marks will be indicated

22

by stampings on the arm as follows :

4X

6X

9X

6X

or

9X

12X

or

9X

1 2X

1 5X

At the factory, the pick-up point has been set

at the nameplate value of the instantaneous trip

current. (Usually expressed in times the ampere

rating of the trip coil.) The variation in pick-up

setting is accomplished by varying the tensile

force on the instantaneous spring. Turning the

adjustment screw changes the position of the

movable nut (2 ), Figure 1 1, on the screw. The

spring is anchored to this movable nut so that

when the position of the nut is changed, there is

a corresponding change in the spring load. As

the spring is tightened, the pick-up point is in

creased.

The top edge of the movable nut (2 ),

Figure 11 serves as an index pointer and should

be lined up with the center of the desired calibration

mark, punched slots on operating arm, to obtain

the proper instantaneous trip setting.

www

. ElectricalPartManuals

. com