13

1,2

8 3

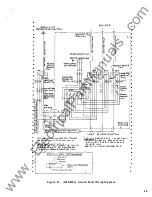

POLE BREAKER

WER�NT

'

- �'

R C

,

._/COIL

, _ _ _

1 _

osu

(Wt£N REQ'O)

070

coo

L3

AIO

oso

I�

.2_

52

R. C.

POITNTIAL

COL

WIRING

TYPICAL

CONNECTION DIAGRAM

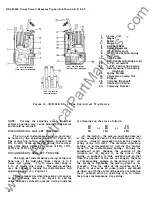

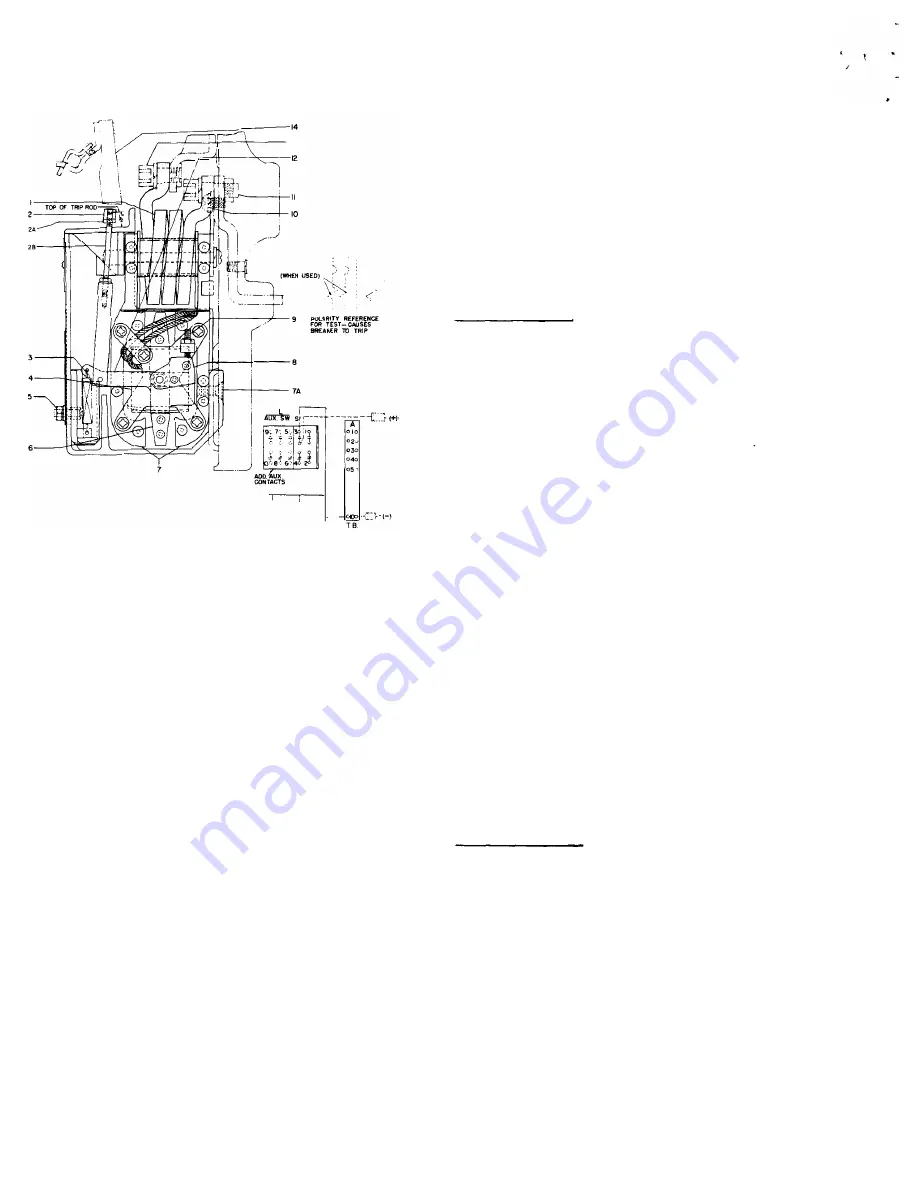

Figure 13. (2 8 6B209) Reverse Current Tripping

Device

1 .

2 .

2A.

2B.

3.

4.

5 .

6 .

7 .

Series Coil

Adjusting Nut

Locking Nut

Trip Rod

Spring

Potential Coil

Calibration Nut

Armature

Pole Pieces

7A.

8 .

9 .

10. '

1 1 .

1 2 .

1 3 .

1 4 .

Screws

Counterweight

Stop Screw

Mounting Screw

Screw (Lower Stud)

Trip C rank

Screw (Lower Stud)

Trip Paddle

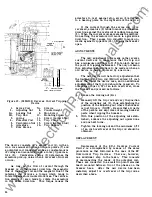

The device consists of a series coil (1), with an

iron core mounted between two pole pieces

(7)

and

a potential coil connected across a constant source

of voltage and mounted around a rotary type arma

ture (6).

Calibration spring (3) determines the

armature pick-up value when a reversal of current

occurs.

As long as the flow of current through the

breaker is in the normal direction, the magnetic

flux of the series coil and the magnetic flux of the

potential coil produce a torque which tends to

rotate the armature counterclockwise. The calibra

tion spring (3) also tends to rotate the armature

in the same direction.

This torque causes the

24

armature to rest against stop screw (9) attached

to a bearing plate on the right side of the device.

If

the current through the series coil (1) is

reversed, armature (6) tends to move in a clockwise

direction against the restraint of calibration spring

(3 ) . When the current reversal exceeds the calibra

tion setting, the armature will move in a clockwise

direction. This causes trip rod (2B) to move up

wards against trip paddle (14), tripping the breaker

open.

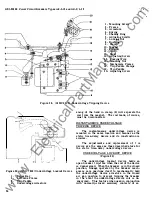

ADJUSTMENTS

The only adjustment to be made on the reverse

current device is to make sure that the trip rod

has a minimum overtravel of 1/32 of an inch beyond

the point of tripping the breaker. The only occasion

this adjustment should have to be made is when an

old device is being replaced by a new one .

The new device will be factory adjusted so that

the top end of the trip rod (2B ) will extend 1/2 inch

above the top of the device case, and no additional

adjustments of the trip rod should be required. To

obtain the proper 1 /32 of an inch overtravel, close

the breaker and proceed as follows :

1 . Loosen the locking nut (2A).

2 . Manually lift the trip rod and vary the position

of the adjusting nut (2), thus establishing the

position of the adjusting nut where the breaker

is just tripped. (NOTE - Be sure that all parts

of the person are kept clear of moving breaker

parts when tripping the breaker.

3 . With this position of the adjusting nut estab

lished, advance the adjusting nut upward one

and one half turns.

4 . Tighten the locking nut and the minimum 1/32

of an inch overtravel of the trip rod should be

obtained.

REPLACEMENT

Replacement of the ED- 1 Reverse Current

Device is accomplished by means of the same

procedure as that followed in the case of the E C

Overcurrent Trip Devices. There i s , however,

one additional step to the taken. This consists

of disconnecting the leads of the potential coil.

These are connected to a small two point terminal

board mounted between two of the phases on the

breaker base.

After the new device has been

installed, adjust for overtravel of the trip rod as

described above.

www

. ElectricalPartManuals

. com