37

COMMISSIONING 10

COMMISSIONING 10

COMMISSIONING 10

COMMISSIONING 10

COMMISSIONING 10

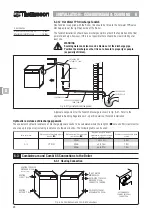

10-3.2 Check Pressure Relief Valve

To check operation of the pressure relief valve temporarily increase the system pressure.

The valve should operate when the pressure increases to 3 Bar ± 10%.

Reduce the pressure on completion by manually operating the pressure relief valve.

10-4

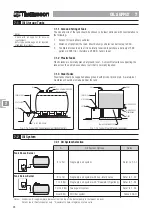

Combustion Tests

Combustion tests must be carried out using an approved test kit.

The householder should be left necessary details of the test.

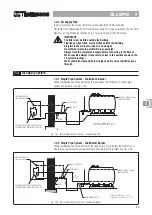

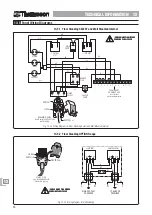

To obtain the above, first fit a manifold and pressure gauge 0-300 p.s.i. to the oil pump.

Next set the Boiler control stat to 80°C and switch on. Ensure all controls are calling for

heat.

Having bled the air out of the system, adjust the pump pressure.

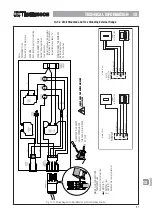

Test holes are provided for all flues.

Check the smoke reading with the Boiler up to temperature and then measure the CO² and

flue gas temperature.

Reducing air into the Burner decreases the flue gas temperature and increases the CO².

See Section 13-4 for typical Burner settings and test data.

IMPORTANT

DO NOT drill any test holes in balanced flues.

Any test hole drilled in a conventional flue must be plugged.

ALWAYS refit test hole bolts.

10-5

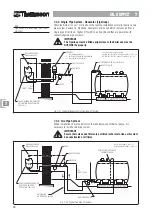

Handing Over

Having filled in the guarantee form, this should be sent to GAH (Heating Products)

Limited. The installer should next recheck the system and ensure it is completely

satisfactory before demonstrating to the householder the operation of the Boiler and its

controls.

The manual must be left with the householder together with a copy of the completed

warranty form.

Also leave the Burner Booklet with the householder and any other manufacturer’s

instructions or details supplied with components.

10

10

10

10

10