20

L

N

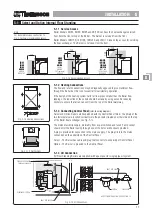

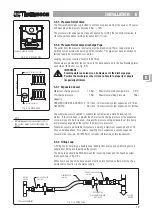

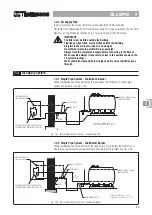

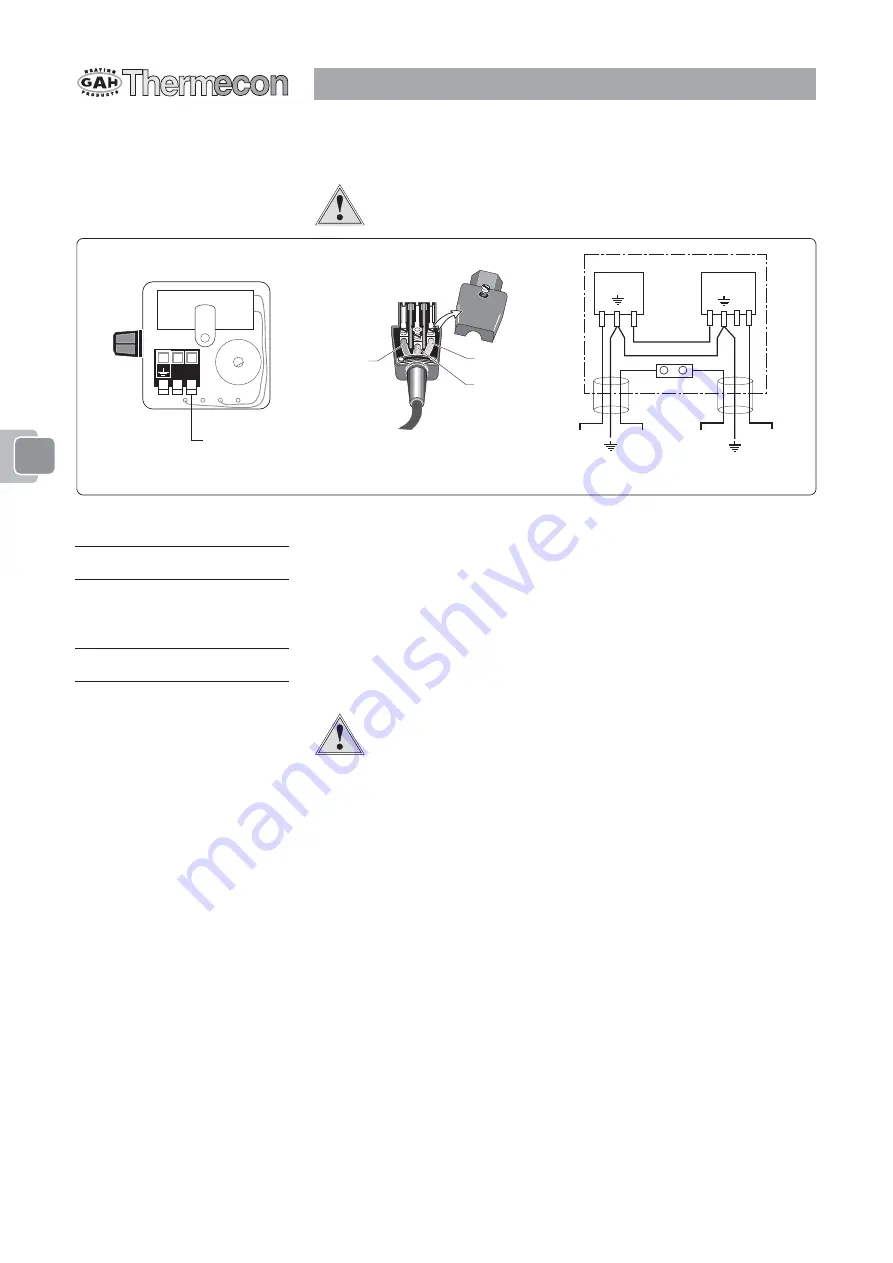

PUMP ELECTRICAL CONNECTIONS

Fig. 5-5f Wiring Connections

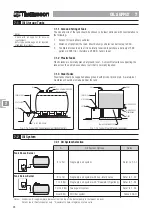

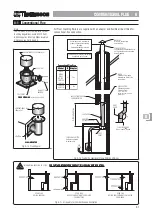

Note

Older systems need careful checking as

they will be operating at a higher pressure.

Note

The expansion vessel is factory set at 1.5

Bar.

5-5.9 Wiring

The wiring of the pump should be done by the installer to best suit the system timer/

programmer.

IMPORTANT

The pump MUST be wired so that it is ON at all times the Boiler is ON.

INST

INST

INST

INST

INSTALLA

ALLA

ALLA

ALLA

ALLATION 5

TION 5

TION 5

TION 5

TION 5

2

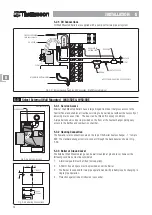

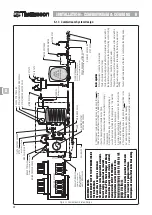

LIMIT STAT

CONTROL STAT

C

2 1

C

L

N

BL

BR

GY

BL

GY

R

TO BURNER

PREWIRED

BR

GY

MAINS SOCKET

PREWIRED

BL

L

N

GY

LIVE BROWN

EARTH G/Y

NEUTRAL BLUE

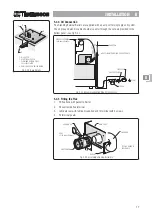

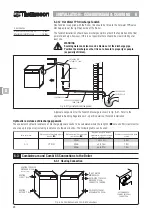

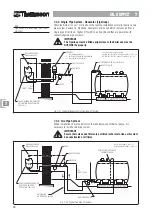

5-5.10 Cold Fill Pressure

The Cold Fill Pressure of the central heating system should be:-

Recommended Pressure - 2 Bar Max. Pressure - 3 Bar Min. Pressure - 1 Bar

It is advised to use a pressure gauge when filling the system to ensure correct pressure.

5-5.11 Expansion Vessel Pressure

The pressure of the expansion vessel should be set at 0.5 Bar below the cold fill pressure.

This should be done prior to filling the system using a conventional car tyre gauge and

pump.

IMPORTANT

The pressure of the expansion vessel cannot be checked when there is

water in the system.

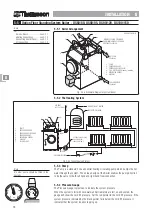

5-5.12 Filling the System

1.

Switch OFF electrical supply to the Boiler.

2.

Check all drain cocks are closed.

3.

Check spare sockets on the Boiler are plugged.

4.

Connect the filling loop.

5.

Open the filling loop isolating valve part-way so that the system fills slowly.

6.

When full and vented make a note of the cold fill pressure on the Boiler pressure

gauge.

7.

Open drain cocks and vent to fully flush the system.

8.

If required, set the expansion vessel pressure to 0.5 Bar below the cold fill pressure

recorded in 6 above.

9.

Check all drain cocks are closed.

10. Refill and vent the system to the correct cold fill pressure see 5-5.7.

The correct amount of suitable corrosion inhibitor should be added to the system

strictly to the manufacturer’s instructions.

11. Shut filling loop isolating valve and disconnect one hose union.

12. Check for leaks.

55555

WIRE TO SWITCHED

PROGRAMME LIVE