15

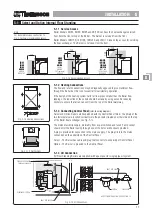

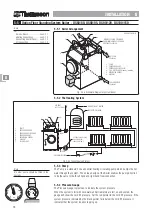

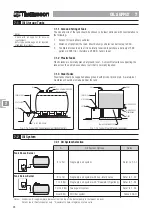

5-3.4 Fixing the Boiler - Suggested Procedure

1. Remove carton.

2. Open Boiler door and remove flue components.

3. Remove Control Panel by unplugging Burner plug and unbolt two nuts.

4. Remove main casing - 3 screws each side.

5. Remove access door and lift out all baffles from heat exchanger.

6. Remove Boiler body from wood transport blocks - 3 screws, 1 top, 2 bottom.

7. Offer back panel to the position required on the wall and use this as a template to

mark the drilling positions for the 3 mounting rawl bolts ‘R’.

Also mark the positions of any holes required through the wall for water pipes, oil

pipes, fire check valve and electric cable.

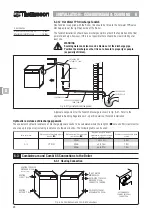

8. Remove panel and accurately drill required holes and fit 3 rawl bolts into holes ‘R’.

9. Place back panel onto the 3 rawl bolts - do not fit nuts.

10. Clear work space and carefully lift the heat exchanger onto the 3 rawl bolts, fit nuts -

do not tighten yet.

11. Adjust for level and tighten the 3 rawl bolts.

12. Make oil pipe connections, see Section 5-3.6.

13. Make water connections.

14. Fit main casing.

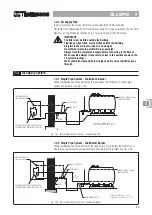

15. Fit flue bend with gasket to Boiler.

16. Fit seal inside flue terminal.

17. Lubricate seal with lubricant supplied and fit terminal with 4 screws.

INST

INST

INST

INST

INSTALLA

ALLA

ALLA

ALLA

ALLATION 5

TION 5

TION 5

TION 5

TION 5

Note

Before removing main case, study the

Burner position and the Boiler wall position

and decide on the best oil pipe

configuration, see Section 5-3.6 and

Section 7.

K x 2

R

R

R

K

R - 3 HOLES DRILL 12Ø FOR RAWL BOLTS

K - KNOCKOUT POSITIONS

Fig. 5-3c Drilling Positions

W

W

W

W

WARNING

ARNING

ARNING

ARNING

ARNING

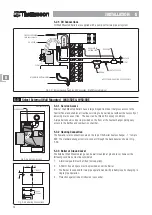

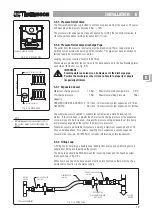

The weight of the Boiler Heat Exchanger

bare is 50kg (110 lbs) - it is a two person

job to lift it in place.

Note

For back panel dimensions, see page 56.

50

50

50

50

50 kg

kg

kg

kg

kg

Fig. 5-3d External Boiler Flue Assembly

18. Re-fit Control Panel.

19. Re-fit Baffles and Access Cover - see page 39.

20. Finally, seal top and both sides externally with sealant provided - ensure GOOD

NEAT SEAL.

IMPORTANT

Do not trap phial capillary tubes behind access cover.

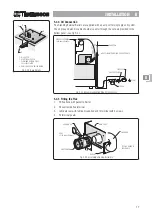

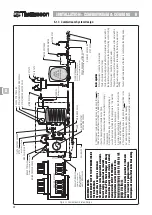

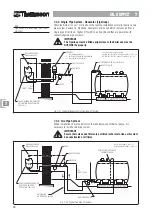

5-3.5 Connecting Control Panel

The three phials of the thermostats are inserted horizontally in the pockets situated in the

heat exchanger, see fig. 5-3e.

The Burner is supplied with a 4 wire cable and plug which connects into the Burner

supply socket on the Control Panel.

The mains electricity supply, preferably from a spur switched and fused 5 amp, should

enter the Boiler casing through one of the holes or knockouts provided, see Fig. 5-3c.

SEAL

FITTED INSIDE TERMINAL

SCREWS X 4

MAIN CASE

FLUE BEND

FLUE TERMINAL

GASKET

1

3

2

Fig. 5-3e Phial Positions

FROST STAT PHIAL

(NO SLEEVE)

POSITION 3

LIMIT AND CONTROL STAT PHIAL

POSITIONS 1 & 2

BURNER CABLE & PLUG

MAINS SUPPLY PLUG

FIT FLUE GUARD IF

APPLICABLE.

55555