29

OIL SUPPL

OIL SUPPL

OIL SUPPL

OIL SUPPL

OIL SUPPLY 7

Y 7

Y 7

Y 7

Y 7

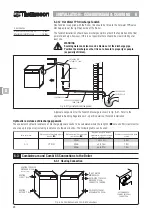

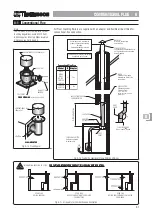

7-2.2 Oil Supply Pipe

In ALL oil systems the vertical lift of the oil line should be 10mm diameter.

Horizontal runs should also be 10mm diameter, however it is good practice to use 15mm

diameter, on the horizontal sections only, of pipe runs longer than 40 metres.

IMPORTANT

The filter must be fitted outside the Building.

Tigerloops, when fitted, must be fitted outside the building.

All joints in the oil line must be oil and air tight.

No soldered joints are permissible in supply pipe.

Always flush the complete oil supply before connecting to the Burner.

When specified always fit non-return valves in the position shown on the

oil system drawings.

Walls should be sleeved where oil pipes and fire valve capillaries pass

through.

7-3

Oil Supply System

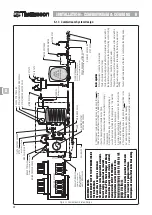

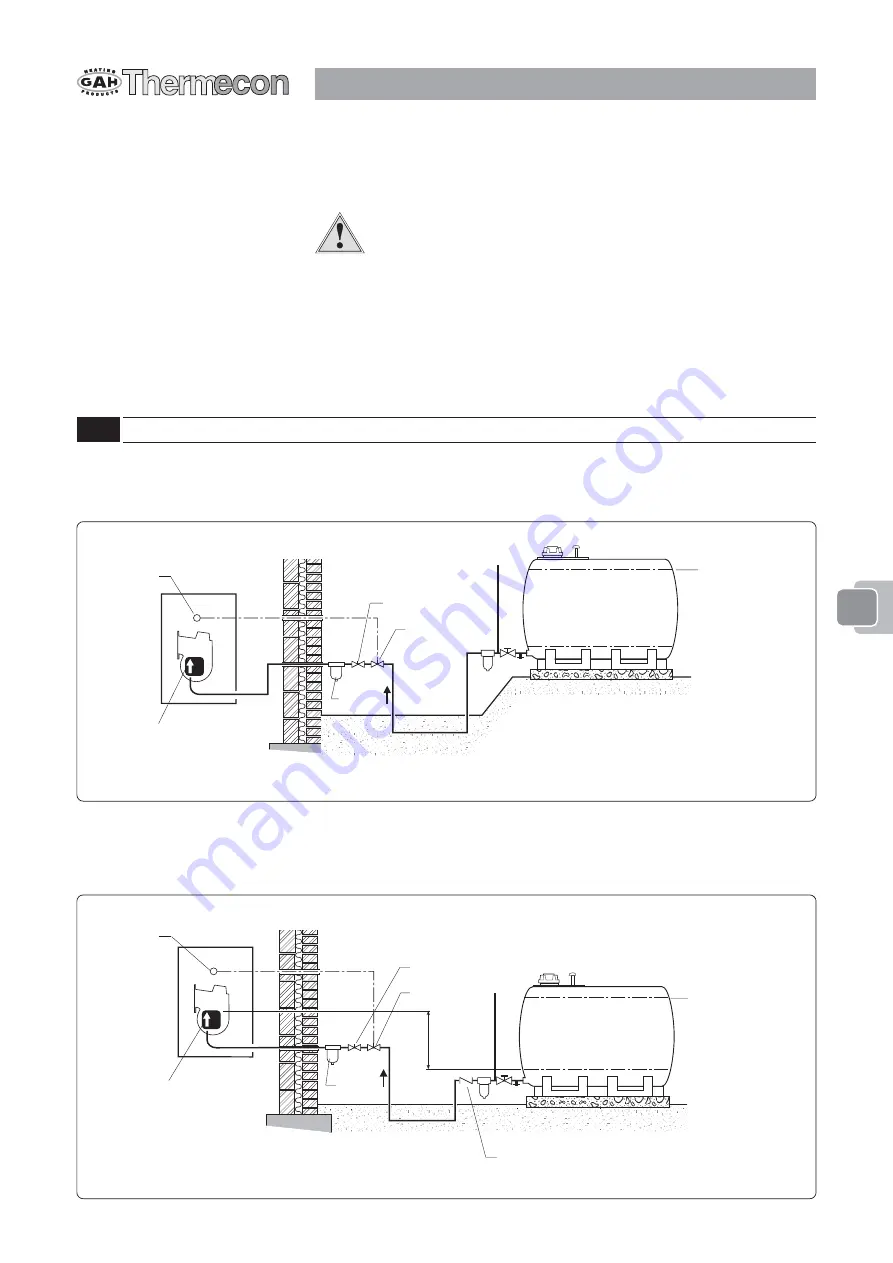

7-3.1 Single Pipe System - Tank Above Burner

Where installations have the bottom of the tank above the Oil Burner, a single pipe

system can be used, see fig. 7-3a.

Fig. 7-3a Typical Single Pipe Oil System - Tank Above Burner

MAX. OIL LEVEL 4 metres

ABOVE BURNER

SHUT OFF VALVE

FILTER

THE OIL BURNER PUMP SHOULD BE SET

FOR SINGLE PIPE OPERATION, SEE 13-4.5.

FIRE VALVE SENSOR

FIXED ABOVE BOILER

FIRE VALVE

PLASTIC TANK SHOWN - SEE 7-1.2

STEEL TANK ALSO SUITABLE - SEE 7-1.3

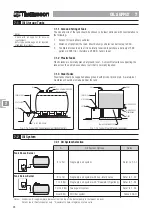

7-3.2 Single Pipe System - Tank Below Burner

Where installations have the bottom of the tank up to 1 metre below the Oil Burner, a

single pipe system can be used providing a non-return valve is fitted, see fig. 7-3b.

MAX. OIL LEVEL 4 metres

ABOVE BURNER

SHUT OFF VALVE

FILTER

THE OIL BURNER PUMP SHOULD BE SET

FOR SINGLE PIPE OPERATION, SEE 13-4.5.

FIRE VALVE SENSOR

FIXED ABOVE BOILER

FIRE VALVE

PLASTIC TANK SHOWN - SEE 7-1.2

STEEL TANK ALSO SUITABLE - SEE 7-1.3

LIFT UP

TO 1M

NON-RETURN VALVE

Fig. 7-3b Typical Single Pipe Oil System - Tank Below Burner

77777