UP/DOWN Control

Low Limiter

Slip Compensation 1

Automatic Deceleration

Overload Prevention Control

Deceleration Characteristics

Torque Limiter

(Frequency increment limit for braking)

Output Current Fluctuation Damping Gain for Motor 1

Reserved.

*3

C1 Disconnection Detection Time

(PID control feedback line)

Cumulative Motor Run Time 1

DC Braking

STOP Key Priority/

Start Check Function

Clear Alarm Data

Protection/Maintenance Function

0 : 0.00

1 : Last UP /DOWN command value on releasing run command

0 : Limit by F16 (Frequency limiter: Low) and continue to run

1 : If the output frequency lowers less than the one limited by F16 (Frequency limiter: Low), decelerate to stop the motor.

0.0 (Depends on F16 (Frequency limiter: Low))

0.1 to 60.0

0 : Enable during ACC/DEC and enable at base frequency or above

1 : Disable during ACC/DEC and enable at base frequency or above

2 : Enable during ACC/DEC and disable at base frequency or above

3 : Disable during ACC/DEC and disable at base frequency or above

0 : Disable

2 : Enable (Canceled if actual deceleration time exceeds three times the one specified by F08/E11.)

4 : Enable (Not canceled if actual deceleration time exceeds three times the one specified by F08/E11.)

0.00 : Follow deceleration time specified by F08/E11 0.01 to 100.0

999: Disable

0 : Disable

1 : Enable

0.0 to 400.0

0.00 to 0.40

0.0: Disable

0.1 to 60.0: Detection time

Change or reset the cumulative data

0 : Slow

1 : Quick

Setting H97 data to "1" clears alarm data and then returns to zero.

0 to 31: Display data on the keypad's LED monitor in decimal format (In each bit, "0" for disabled, "1" for enabled.)

Bit 0 : Lower the carrier frequency automatically

Bit 1 : Detect input phase loss

Bit 2 : Detect output phase loss

Bit 3 : Select life judgment threshold of DC link bus capacitor

Bit 4 : Judge the life of DC link bus capacitor

-

-

0.1

-

-

0.01

-

0.1

0.01

-

-

-

-

-

-

-

-

Hz

-

-

Hz/s

-

Hz

-

-

-

-

-

-

-

1

0

1.6

0

0

999

0

5.0

0.20

0.0

-

1

0

0

19

(bit 4,1,0=1)

25.0 to 400.0

25.0 to 400.0

0: Output a voltage in proportion to input voltage

80 to 240: Output an AVR-controlled voltage (for 230 V class series)

160 to 500: Output an AVR-controlled voltage (for 460 V class series)

80 to 240V: Output an AVR-controlled voltage (for 230 V class series)

160 to 500V: Output an AVR-controlled voltage (for 460 V class series)

0.0 to 20.0(percentage with respect to "A03: Rated Voltage at Base Frequency 2")

Note: This setting takes effect when A13 = 0, 1, 3, or 4.

1 : For a general-purpose motor with shaft-driven cooling fan

2 : For an inverter-driven motor, non-ventilated motor, or motor with separately powered cooling fan

0.00 : Disable 1 to 135% of the rated current (allowable continuous drive current) of the motor

0.5 to 75.0

0.0 to 60.0 Hz

0 to 100

0.00 : Disable 0.01 to 30.00

0.1 to 60.0

0 : Variable torque load

1 : Constant torque load

2 : Auto-torque boost

3 : Auto-energy saving operation (Variable torque load during ACC/DEC)

4 : Auto-energy saving operation (Constant torque load during ACC/DEC)

5 : Auto-energy saving operation (Auto-torque boost during ACC/DEC)

0 : V/f operation with slip compensation inactive

1 : Dynamic torque vector operation

2 : V/f operation with slip compensation active

3 : V/f operation with PG

4 : Dynamic torque vector operation with PG

0.1

0.1

1

1

0.1

-

0.01

0.1

0.1

1

0.01

0.1

-

-

Hz

Hz

V

V

%

-

A

min

Hz

%

s

Hz

-

-

Y

Y

Y2

Y2

Y

Y

Y1Y2

Y

Y

Y

Y

Y

Y

Y

60.0

60.0

230

460

230

460

Depending on

the inverter capacity

1

100% of the motor rated current

5.0

0.0

0

0.00

0.5

1

0

(Initial frequency setting)

(Mode selection)

(Lower limiting frequency)

(Operating conditions)

(Mode selection)

(Braking response mode)

(Mode selection)

Y

Y

Y

Y

Y

Y

Y

Y

Y

N

Y

Y

N

Y

STOP key priority

Start check function

Item

Data

0

Disable

Disable

1

Enable

Disable

2

Disable

Enable

3

Enable

Enable

Maximum Frequency 2

Base Frequency 2

Rated Voltage at Base

Frequency 2

Maximum output Voltage 2

Torque Boost 2

Electronic Thermal Overload Protection for Motor 2

DC

Braking 2

Starting Frequency 2

Load Selection/

Auto Torque Boost /

Auto Energy Saving Operation 2

Control Mode Selection 2

(Select motor characteristics)

(Overload detection level)

(Thermal time constant)

(Braking starting frequency)

(Braking level)

(Braking time)

*3 Reserved for the maker. Do not set any data.

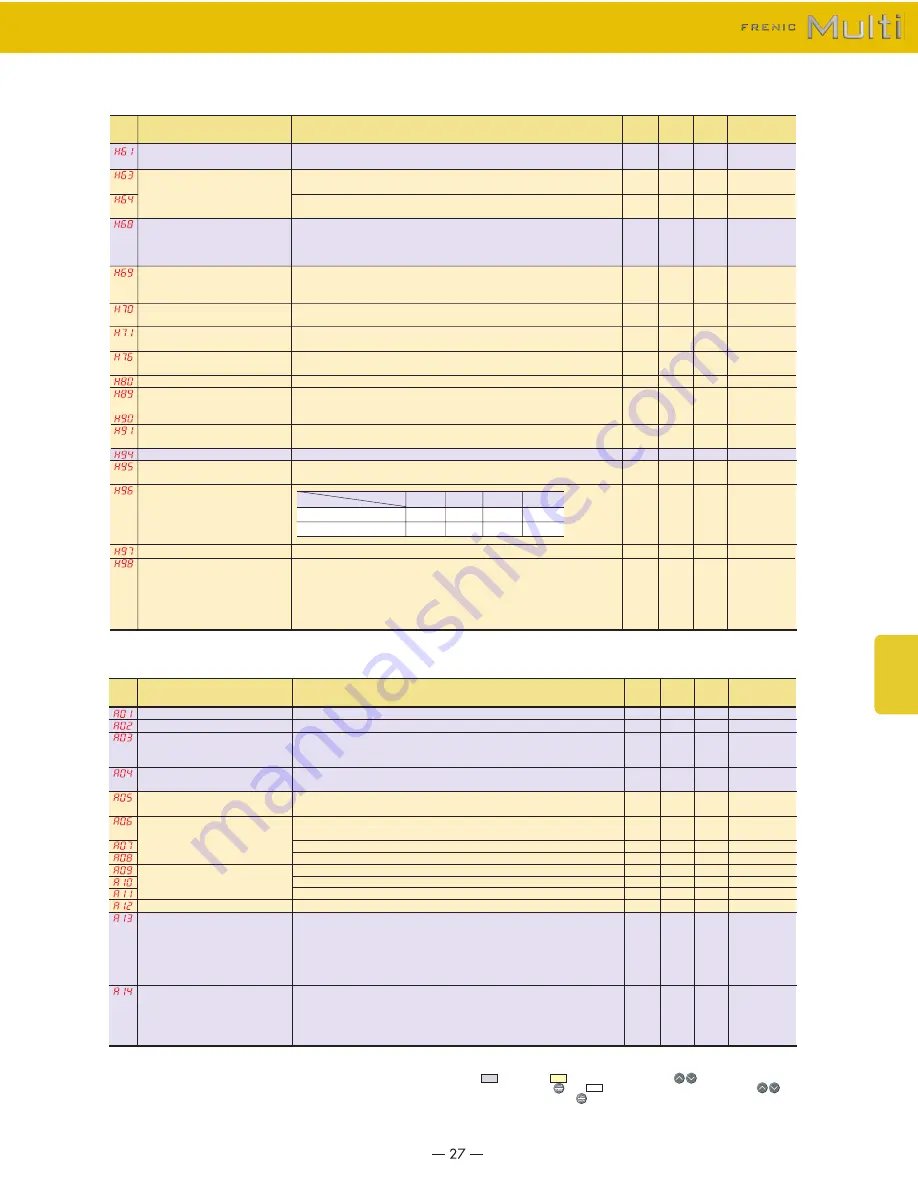

<Changing, validating, and saving function code data when the motor is running>

: Impossible, : Possible (Change data with keys and then

save/validate it with key), : Possible (Change and validate data with

keys and then save it with key)

●

A codes: Motor 2 Parameters

●

H codes: High Performance Functions

Func.

Code

Data

copy

*2

Name

Data setting range

Default setting

Min.

Unit

Func.

Code

Data

copy

*2

Name

Data setting range

Default setting

Min.

Unit

*1 When you make settings from the keypad, the incremental unit is restricted by the number of

digits that the LED monitor can display.

(Example) If the setting range is from -200.00 to 200.00, the incremental unit is as follows:

"1" for -200 to -100, "0.1" for -99.9 to -10.0, "0.01" for -9.99 to -0.01, "0.01" for 0.00 to 99.99,

and "0.1" for 100.0 to 200.0

*2 Symbols in the "Data copy" column

Y: Will be copied unconditionally.

Y1: Will not be copied if the rated capacity differs from the source inverter.

Y2: Will not be copied if the rated input voltage differs from the source inverter.

N: Will not be copied.

~

Functions

Settings

Содержание FRN001E1E-2U

Страница 1: ...MEH531 High Performance Compact Inverters...

Страница 38: ...MEMO...

Страница 39: ...MEMO...