●

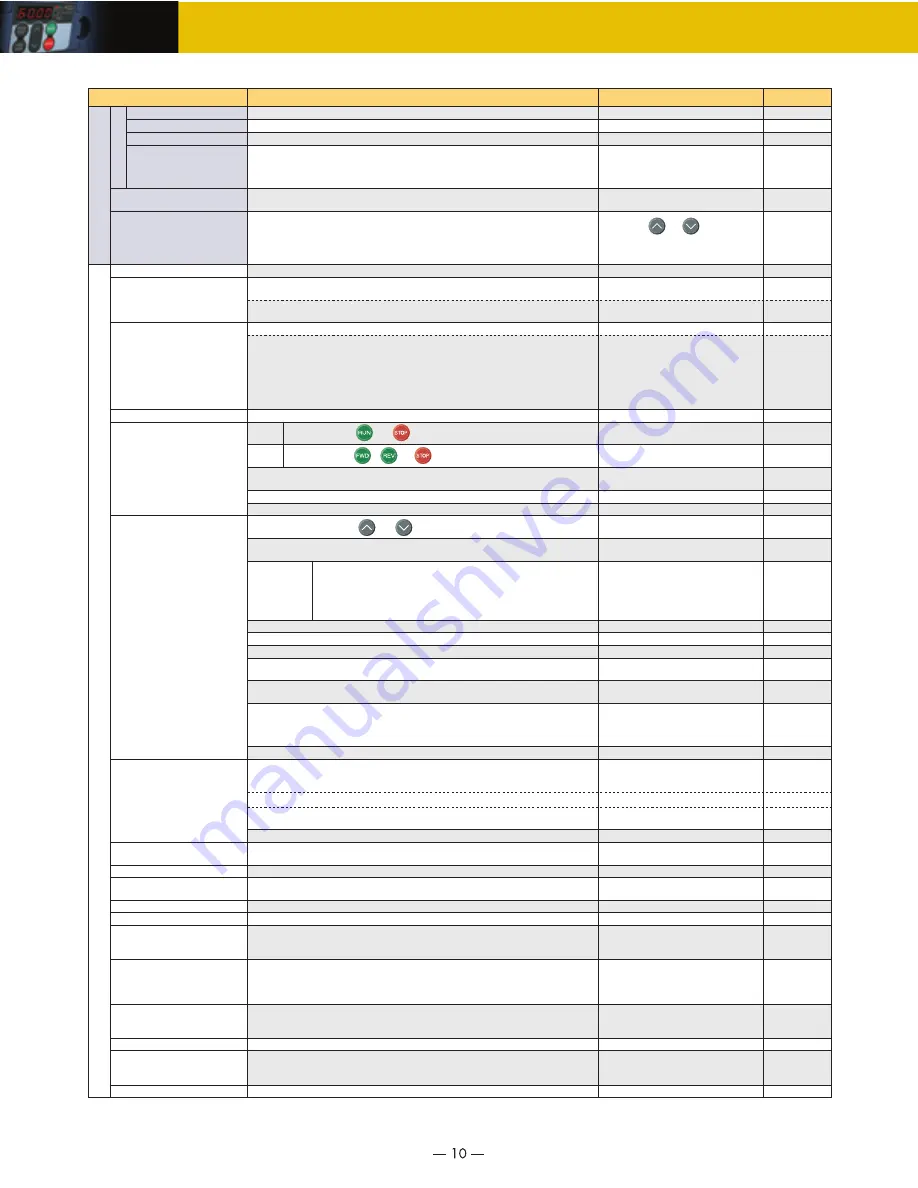

Common specifications

Maximum frequency

Base frequency

Starting frequency

Carrier frequency

Item

Explanation

Related

function code

Remarks

25 to 400Hz variable setting

25 to 400Hz variable setting

0.1 to 60.0Hz variable setting, Duration: 0.0 to 10.0s

•

Analog setting:

±

0.2% of maximum frequency (at 25

±

10

˚

C(at 77

±

50

˚

F))

•

Keypad setting:

±

0.01% of maximum frequency (at -10 to +50

˚

C(at 14 to +

122

˚

F))

•

V/f control

•

Dynamic torque-vector control (magnetic flux estimator)

•

V/f control (with sensor, when the PG interface card (option) is installed)

2 points (Desired voltage and frequency can be set.)

Torque boost can be set with the function code F09.

Set when 0, 1, 3, or 4 is selected at F37.

200% or over (Auto torque boost in 0.5Hz operation, slip compensation and auto torque boost)

Select application load type with the function code F37.

0: Squared variable torque load

1: Constant torque load

2: Auto torque boost

3: Auto energy-save operation (variable torque load in deceleration)

4: Auto energy-save operation (constant torque load)

5: Auto energy-save operation (auto torque boost)

0.75 to 15kHz variable setting

Frequency may drop automatically to protect the

inverter depending on environmental

temperature and output current.This protective

operation can be canceled by function code H98.

Setting with and keys

•

Analog setting: 1/3000 of maximum frequency (ex. 0.02Hz at 60Hz, 0.4Hz at 120Hz)

•

Keypad setting: 0.01Hz (99.99Hz or less), 0.1Hz (100.0Hz or more)

•

Link setting: Selectable from 2 types

•

1/2000 of maximum frequency (ex. 0.003Hz at 60Hz, 0.006Hz at 120Hz)

•

0.01Hz (fixed)

Possible to set output voltage at base frequency and at maximum output frequency (common spec).

AVR control can be turned ON or OFF (Factory setting: OFF).

Three-phase 230V, single-phase 230V: 80 to 240V

Three-phase 460V: 160 to 500V

Three-phase and single-phase 230V: 0 to 240V/0 to 400Hz

Three-phase 400V: 0 to 500V/0 to 400Hz

Keypad

operation

Key operation: Can be set with and keys

Start and stop with and keys

Start and stop with / and keys

External signals (7digital inputs): FWD (REV), RUN, STOP commands (3 wire operation possible),

coast-to-stop, external alarm, alarm reset, etc.

Linked operation: Operation through RS-485 or field buss (option) communications

Switching operation command: Link switching, switching between communication and inverter (keypad or external signals)

Keypad (standard)

Multi-function keypad

With data protection

Connected to analog input terminals 13, 12,

and 11. Potentiometer must be provided.

Multistep frequency: Selectable from 16 steps (step 0 to 15)

UP/DOWN operation: Frequency can be increased or decreased while the digital input signal is ON.

Linked operation: Frequency can be set through RS-485 or field buss (optional) communications.

Switching frequency setting: Frequency setting can be switched (2 settings) with external signal (digital input).

Switching to frequency setting via communication and multi-frequency setting are available.

Auxiliary frequency setting: Terminal 12 input and terminal C1 input (terminal V2 input) can be added

to main setting as auxiliary frequency.

Inverse operation: Normal/inverse operation can be set or switched with digital input signal and

function code setting.

•

+10 to 0V DC /0 to 100% (terminal 12, C1 (V2))

•

+20 to +4mA DC/0 to 100% (terminal C1)

0.00 to 3600s

*If 0.00s is set, the time setting is cancelled and acceleration and deceleration is made

according to the pattern given with an external signal.

Acceleration and deceleration time can be independently set with 2 types and selected with digital input signal (1 point).

Acceleration and deceleration pattern can be selected from 4 types:

Linear, S-curve (weak), S-curve (strong), Non-linear

Deceleration with coasting can be stopped with operation stop command.

Pulse train input: 30kHz (max.)/ Maximum output frequency

When the PG interface card (optional) is installed.

If the set frequency is lower than lower limit, continuous

motor running or stop running motor can be selected.

External volume: Can be set with external potentiometer (1 to 5k

Ω

1/2W)

Analog input

Analog input can be set with external voltage/current input

•

0 to

±

10V DC (0 to

±

5V DC)/0 to

±

100% (terminal 12, C1 (V2))

•

+4 to +20mA DC/0 to 100% (terminal C1)

Accuracy (Stability)

Setting resolution

Control method

Voltage/freq. characteristic

Torque boost

Starting torque

Start/stop

Frequency setting

Acceleration/deceleration time

Frequency limiter

(Upper limit and lower limit frequencies)

Bias

Gain

Jump frequency

(Non-linear V/f setting)

(Load selection)

(Curve)

High and Low limiters can be set. (Setting range: 0 to 400Hz)

Bias of set frequency and PID command can be independently set (setting range: 0 to

±

100%).

Analog input gain can be set between 0 and 200%.

Three operation points and their common jump width (0 to 30.0Hz) can be set.

Timer operation

The inverter operates and stops for the time set with the keypad (1-cycle operation).

Jogging operation

Auto-restart after momentary

power failure

Current limit

Slip compensation

•

Can be operated using digital input signal or keypad.

•

Acceleration and deceleration time (same duration used only for jogging) can be set.

•

Jogging frequency: 0.00 to 400.0Hz

•

Restarts the inverter without stopping the motor after instantaneous power failure.

•

Select "Continuous motor mode" to wait for the power recovering with low output frequency.

•

Restart at 0Hz, restart from the frequency used before momentary power failure, restart at the set frequency can be selected.

•

Motor speed at restart can be searched and restarted.

Voltage signal from terminal 12, C1 (V2) and current

signal (from terminal C1) can be set independently.

F03

F04

F23,F24

F03 to F06

H50 to H53

F09, F37

F09, F37

H68, F37

F02

F02

E01 to E05

E98, E99

H30, y98

F01, C30

F18, C50,

C32 to C34,

C37 to C39,

C42 to C44

C05 to C19

F01, C30

H30, y98

F01, C30

E61 to E63

C53

F07, F08

E10,E11

H07

H11

F15, F16

H63

F18, C50 to C52

C32, C34, C37

C39, C42, C44

C01 to C04

C21

H54

C20

F14

H13 to H16

H92, H93

F26

F27

H98

Keeps the current under the preset value during operation.

Torque limit

•

Controls the output torque lower than the set limit value.

•

Can be switched to the second torque limit with digital input signal.

•

Soft start (filter function) is available when switching the torque control to 1/2.

F43, F44

F40, F41

E16, E17

H76

H68

P09 to P12

H28

•

Compensates for decrease in speed according to the load, enabling stable operation.

•

Time constant can be changed. Possible to enable or disable slip compensation during

acceleration/deceleration or in constant output range.

Droop control

H28

Decrease the speed according to the load torque.

Setting range

Output frequency

Control

•

0 to +5V DC can be used depending on the

analog input gain (200%). +1 to +5V DC can

be adjusted with bias and analog input gain.

•

Voltage can be input (terminal V2) to the

terminal 1.

Specifications

Содержание FRN001E1E-2U

Страница 1: ...MEH531 High Performance Compact Inverters...

Страница 38: ...MEMO...

Страница 39: ...MEMO...