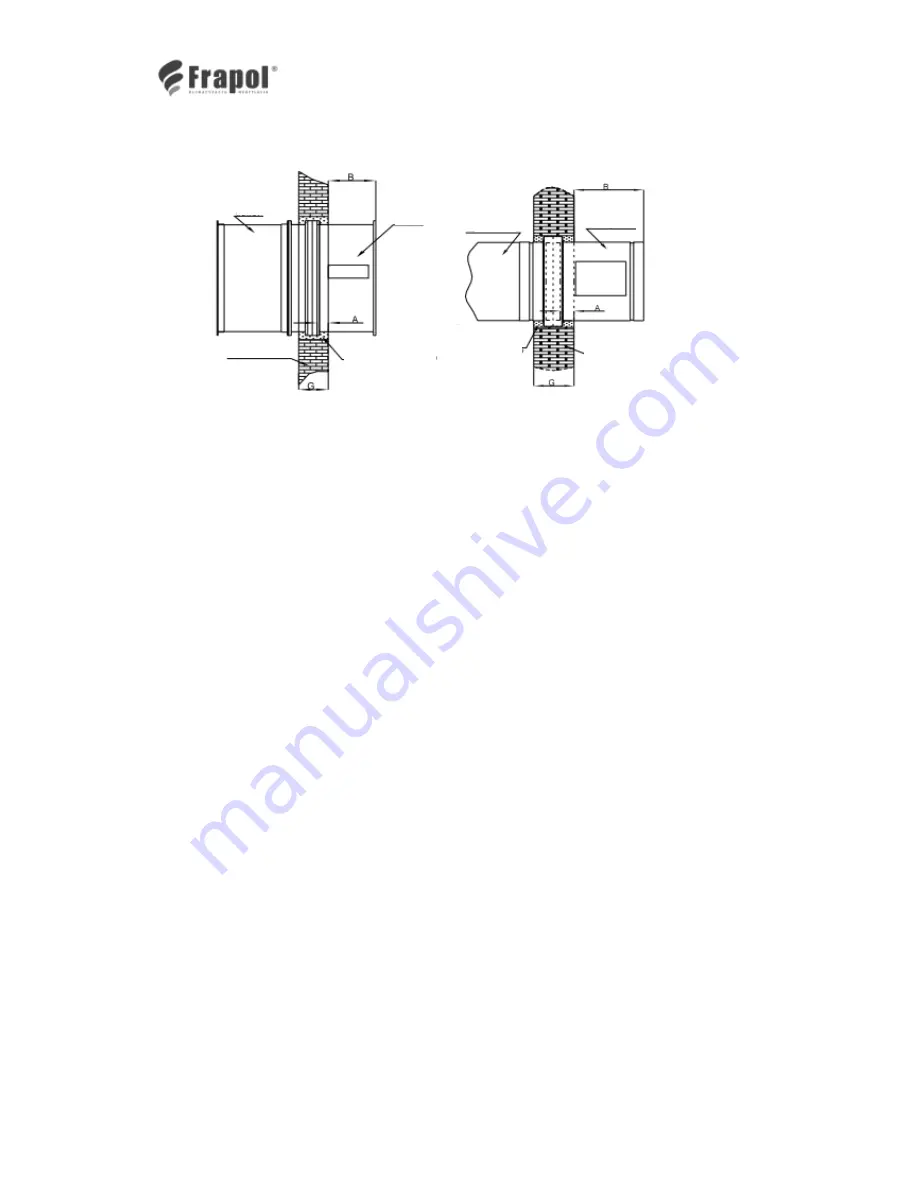

Type V370

Type RK370

Fig. 6a

Fig. 6b

4.4.1.3.

The gap between the valve casing and the fire barrier must be carefully filled with cement,

lime-cement mix or PROMASTOP MG III fire-protective mortar. It is prohibited to force in any

pieces of brick or concrete while sealing, as this might lead to deformation of the casing

(particularly in cases of valves with large cross-sections), and thus prevent free rotation of the

partition and its closure (friction in slide bearings, or friction between the partition and the

casing).

4.4.2. Valves installed in a light fire barrier made of plaster and cardboard boards acc. to diagram in

Fig. 7a and 7b.

4.4.2.1. Place the valve in the fire barrier opening prepared acc. to section 4.2.2. so that, for barrier

with class EI120 and thickness of 125 mm, the cut-off partition of the valve should remain in

the axis of barrier thickness. Valves of V370 type must protrude from the wall on the drive side

to the distance of 218 mm, while valves of RK370 type must protrude from the wall on the

drive side to the distance of 213 mm. Assembly of valves in this version in fire barriers with

lower fire resistance classes must be made observing valve setting against the barrier acc. to

the data in Table 2.

4.4.2.2. Connect the valves with the suspended ventilation ducts on both sides of the fire barrier.

4.4.2.3. After appropriate valve setting in the fire barrier, seal it with mineral wool with thickness of min.

100 kg/m

3

and cover the wall with plaster boards acc. to Fig. 7a; 7b and 7c.

duct

duct

valve

valve

drive

Fire barrier

Fire barrier

Cement, lime-cement

mortar or promastop MG

III

Cement, lime-cement

mortar or promastop

MG III

Drive board