Installation

5

For parts or assistance, call Flotec Customer Service at

1-800-365-6832

NOTE:

Installation of a low pressure safety cutoff

switch on the pump discharge is recommended (and

may be required by your local code) to shut off the

power in case of low discharge pressure (caused by

broken pipe, etc.).

2. Mount the pump on a solid base in the location you

have decided on.

3. Choose a time that will allow you to shut off the

water to the household while you install the

PressureMate.

4. Shutoff the main water supply valve to the household.

5. Open any faucet to relieve water pressure in the

plumbing. Once the water pressure is relieved, close

the faucet.

6. READ STEP 6 COMPLETELY BEFORE STARTING TO

WORK ON IT. You must remove a length of pipe

from the main water supply line to allow installation

of elbows for the PressureMate. The locations of the

cuts must take into consideration the size of the

elbows being used, the length of the threads in

threaded joints or the overlap in glued or soldered

joints, etc.. Position the elbows in line with the pump

suction and discharge threads. There may be slight

water leakage while cutting the pipe. Remove any

burrs or shavings caused by the cutting tool.

NOTE:

Galvanized pipe may not need to be cut. If

there is a union close to the pump location, disas-

semble the union and remove (unscrew) pipe back

past the pump location. Have new lengths of pipe cut

and threaded to allow for the pump installation.

NOTE:

Both female suction and male discharge ports

have 1” NPT threads. Depending on your type of

connection and the size of your home’s piping, you

may need to install adapters on the ports.

7. Once the short piece of pipe is removed, the piping

above the cut can be drained to prevent water mess.

Place a pail under the opening going to the house-

hold. Open the highest faucet in the system to let in

air so the water can fall out of the pipes into the pail.

Once it’s drained, close the faucet.

8. Install the elbows in the main water supply line. Point

them toward the pump.

Risk of burst hose and flooding.

Do not

install with flexible hoses. Use only rigid piping that

meets code.

9. Install piping from elbows to pump including a union

in each line and a check valve in the pump suction

line. The arrow on the check valve must point to the

pump suction (see Figure 2). If not already in the

plumbing system, install a pressure relief valve in the

pump discharge line capable of passing the full pump

flow at 100 psi (689 kPa). If local code requires

installation of a pressure relief valve capable of han-

dling the full pump flow at a pressure less than 100

psi (689 kPa), follow the code requirements. A low

pressure safety cutoff switch should also be installed

in the discharge line, and may be required by your

local codes.

10. With all pipe and fittings installed and sealed, turn on

the main water supply slowly to pressurize the system

and check for leaks. If any leaks appear, turn the

main valve off, open a faucet to relieve the pressure,

and repair the leak. Repeat this step until there are no

leaks in the system.

11. Open a faucet to release the air from the pipes and

allow water to flow. When a steady stream of water

flows out of the faucet, the pump is full of water and

fully primed. Close the faucet.

12. Turn the controller knob to the desired pressure for

the pump to turn on. The PressureMate comes factory

preset at 30 psi (207 kPa), and we recommend start-

ing there and adjusting it later according to your

experience with the system.

13. Before continuing with the installation, see the sections

of this manual titled “Electrical Connections”,

“Automatic Pressure Controller”, “Normal Operation”,

and “When Does The Pump Stop Operating” for

detailed information on how the system functions.

14. At this point, you can plug in the pump for the first

time. When you plug in the power cord, the pump

will start and run for 15 seconds regardless of the

controller setting. If the inlet pressure is above the set

point, the pump will stop after 15 seconds.

15. When the pump is running and after it shuts off auto-

matically, the system is at the boosted pressures.

Inspect the pipe and fittings again for water leaks. If

any leaks appear, unplug the pump, turn the water

main valve off, open a faucet to relieve the pressure

and repair the leak. Repeat this step until there are no

leaks in the system.

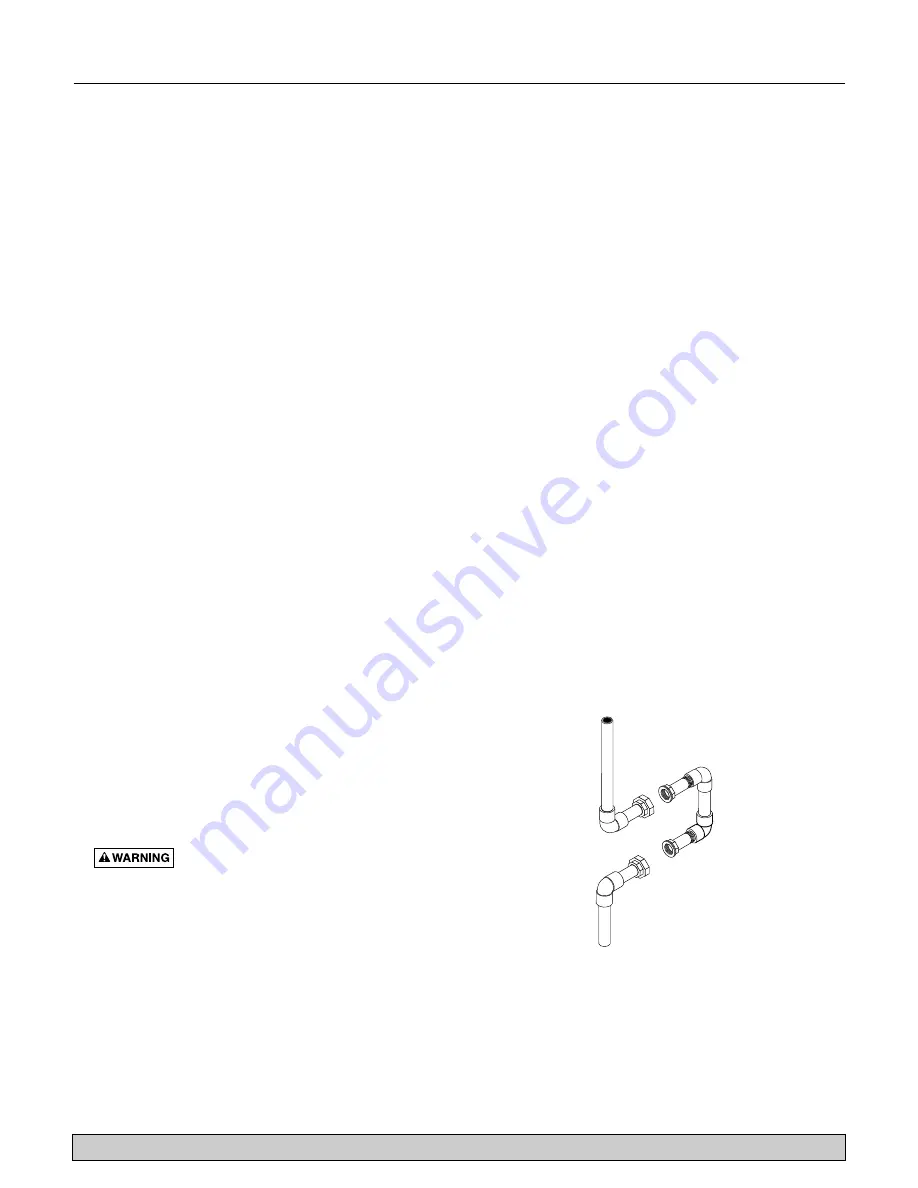

Water

Supply In

To

Household

Figure 3:Typical bypass piping needed to allow removal of

pump for repair without shutting down household water

system.