User Manual X8400 sc

29

6 RADIOMETRIC MEASUREMENT WITH THE X8400sc

6.1 Non Uniformity Correction

General

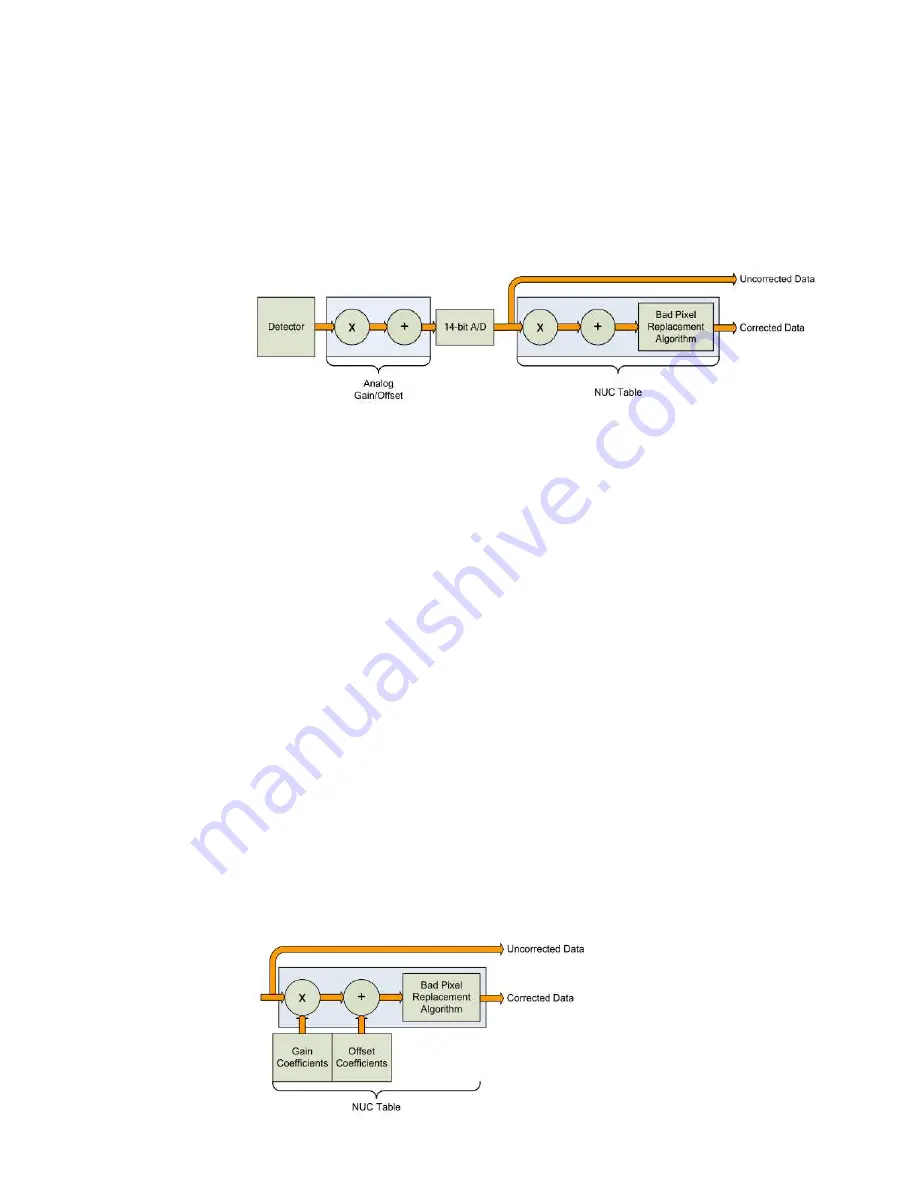

Non-Uniformity Correction (NUC) refers to the process by which the camera electronics

correct for the differences in the pixel-to-pixel response of each individual pixel in the detector

array. The camera can create (or allow for the user to load) a Non-Uniformity Correction

(NUC) table which consists of a unique gain and offset coefficients and a bad pixel indicator

for each pixel. The table is then applied in the digital processing pipeline as shown in Figure

4. The result is corrected data where each pixel responds consistently across the detector

input range creating a uniform image.

Figure 4: Digital Process showing application of NUC tables

To create the NUC table, the camera images either one or two uniform temperature sources.

The source is an external source provided by the user. The source should be uniform and

large enough to overfill the camera field-of-view (FOV). By analyzing the pixel data from

these constant sources, the non-uniformity of the pixels can be determined and corrected.

There are two types of processes which are used to create the NUC table: One-Point and

Two-Points.

6.1.1 CNUC™

General

CNUC is a proprietary calibration process. A camera calibrated with CNUC™ allows for

flexible integration time adjustments without the need to perform non-uniformity corrections.

Additionally, the CNUC™ calibration produces accurate measurement stability regardless of

camera exposure to ambient temperature variations.

A CNUC™ correction is valid for a specific optical configuration composed of a combination

of lens and spectral filers. CNUC™ corrections are generated by FLIR service offices where

advanced calibration benches are available. Contact your FLIR representative to proceed to

CNUC™ correction on new spectral filters or infrared lenses.

CNUC™ process generates a gain and offset map based upon camera internal parameters

and environmental probes.

6.1.2 Two-Point Correction Process

General

The Two-Point Correction Process builds a NUC table that contains individually computed

gain and offset coefficients for each pixel as seen in Figure 5. Two uniform sources are

required for this correction. One source at the low end and a second source at the upper end

of the usable detector input range.

Figure 5: Two Points Correction

Содержание X8400sc

Страница 1: ...User Manual X8400 sc 1 X8400sc User Manual Document Number DC085U Version C Issue Date 08 03 2013...

Страница 42: ...User Manual X8400 sc 42 4 Connect to http 192 168 64 1...

Страница 48: ...User Manual X8400 sc 48 7 3 Mechanical General Below are the mechanical interfaces...

Страница 49: ...User Manual X8400 sc 49...

![Navig[8]r NAVCAM-717D User Manual preview](http://thumbs.mh-extra.com/thumbs/navig-8-r/navcam-717d/navcam-717d_user-manual_3571056-01.webp)