58

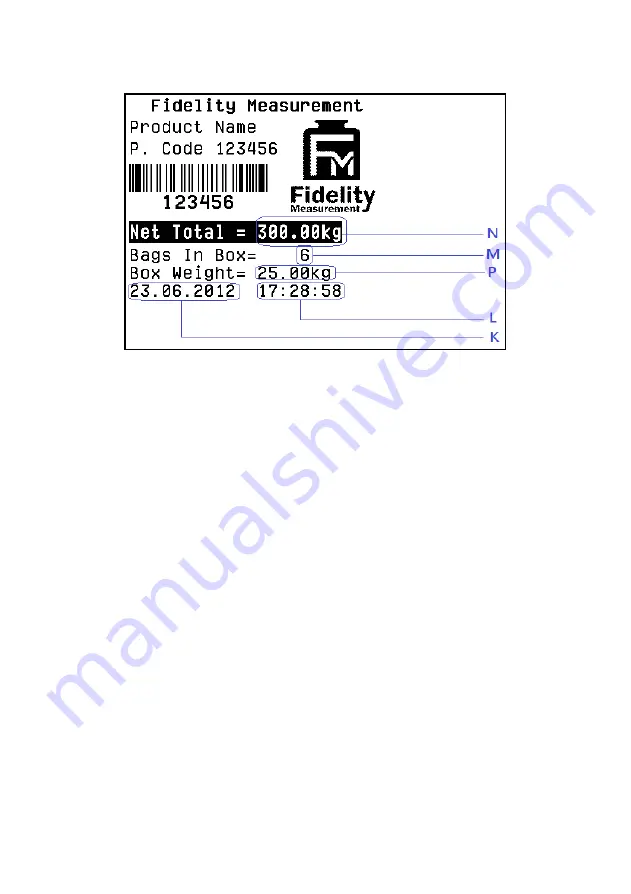

16.2.2.2 Sample label of totalized data (FL2)

16.3 Quick Access to Label Settings

If label printer is selected either for Comport 1 or Comport 2, follow the below

procedures to access quick label settings during operation.

1.

Press

[Set]

.

2.

Instrument displays F1.

3.

Press

[Check]

, instrument displays number of copy to generate each

time. Press

[Func]

or

[Unit]

until the preferred parameter appears

then press

[Print/M+]

to save.

4.

Instrument displays label file number (FL1 01 ~ FL1 99) to print

in label format group 1. Press

[Func]

or

[Unit]

until the preferred

label file number appears then press

[Print/M+]

to save.

5.

Instrument displays label file number (FL2 01 ~ FL2 99) to print

in label format group 2. Press

[Func]

or

[Unit]

until the preferred

label file number appears then press

[Print/M+]

to save.

6.

At this point, label settings are completed.

Содержание 19e

Страница 2: ...2 ...

Страница 63: ...63 22 Appendix B PC Output Protocols ...

Страница 64: ...64 ...

Страница 65: ...65 ...

Страница 73: ...73 Fidelity Measurement Co Ltd http www fi measurement com e mail info fi measurement com ...