Protective func-

tions

Description

Measures required during installa-

tion and commissioning

Electronic current

limiting and I²t mon-

itoring of the motor

current

The motor current is

monitored electronically

and limited in accordance

with the limit values

specified in the standard

è

EN 61800-5-1, Tab. 29.

Motor currents and I²t time

constant can be parameter-

ised.

–

Parameterise the nominal current, max-

imum current and I²t time constant of the

motor, e.g. using the device-specific plug-

in.

Thermal memory in

the event of motor

switch-off

supported, cannot be para-

meterised

–

none

Thermal memory in

the event of a power

supply failure

Speed-sensitive over-

load protection

supported from firmware

version V019, parameteris-

able

–

Parameterise I²t monitoring with speed-

dependent scaling, e.g. with the device-

specific plug-in.

Such as for:

–

Synchronous servo motors (lower permis-

sible current at high rotational speed)

–

Fan motors (lower permissible current at

low rotational speed)

Tab. 35: Protective functions for the motor

The specified parameters are preset for Festo motors. The parameters can be

adapted in the plug-in.

7.9.4

Shield support of the motor cable

Requirements for the motor cable shield support on the device side

The type of shield support depends on the design of the motor cable. If,

for example, a hybrid cable is used to connect the motor, holding brake and

temperature sensor, the following options are available for connecting the shield

on the device side:

Option 1: all motor cable shields are jointly connected over a wide surface area

using a shield sleeve at the cable end and are connected below the shield clamp

on the front of the CMMT-AS.

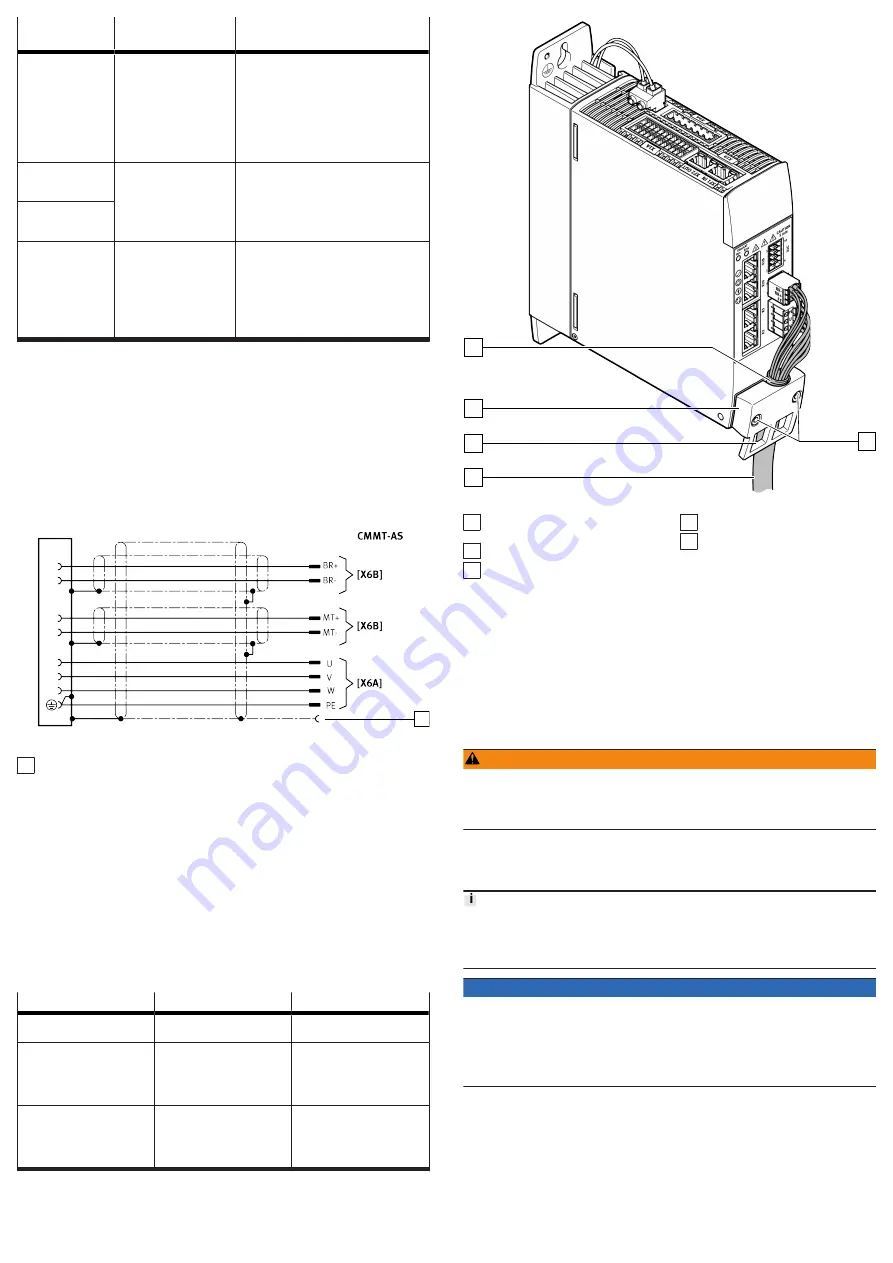

1

Fig. 9: Shared shield support of all cable shields (example)

1 Shield sleeve

Option 2: the outside shield of the motor cable is connected separately over a

wide surface area below the shield clamp on the front of the CMMT-AS. The inside

shields are connected separately to the designated FE pin of the connection [X6B].

•

Make unshielded cable ends as short as possible.

Mounting the shield clamp

The lower section of the front panel of the housing is used as a shield support

surface. The shield support surface, together with the shield clamp, allows the

motor cable shield to be connected over a wide surface area.

1. Using the shield clamp, press the motor cable shield or the conducting

shield end sleeve of the motor cable onto the shield support surface of the

housing

2. Tighten the retaining screws (2x) of the shield clamp with a size T20 TORX

screwdriver. Pay attention to the clamping range and observe the tightening

torque specified below.

Property

Value

Comments

Clamping range

11 mm … 15 mm

Diameter of the stripped cable

or shield sleeve

Tightening torque for the

retaining screws in the case of

block mounting

1.8 Nm ± 15%

In the case of block mounting,

the shield clamp makes full

contact with the base of

the housing (cable diameter

11 mm)

Minimum tightening torque

with larger cable diameter

(

>

11 mm … 15 mm)

0.5 Nm ± 15%

With a higher tightening

torque, make sure that the

connecting cable does not get

crushed in the clamping area

due to excessive pressure.

Tab. 36: Tightening torque and clamping range

1

2

3

4

5

Fig. 10: Shield clamp of the motor cable

1 Retaining screws of the shield

clamp

2 Motor cable

3 Cut-out for mounting cable

binders (2x)

4 Shield clamp

5 Motor cable shield connected

over a large surface area below

the shield clamp

Motor cable shield support on the motor side

Detailed information on the motor-side connection with motor cables from Festo

è

Assembly instructions for the motor cable

•

Connect all shields to the PE over a wide surface area on the motor side,

e.g. via the shield connection provided on the motor connector or the shield

support surface in the motor junction box.

7.10

Power and logic voltage supply

7.10.1

[X9A], power supply and DC link circuit connection

Supply of the control unit (logic voltage supply)

WARNING

Risk of injury due to electric shock.

• For the electrical power supply with extra-low voltages, use only PELV circuits

that guarantee a reinforced isolation from the mains network.

• Observe IEC 60204-1/EN 60204-1.

•

Only connect PELV circuits with an output current of max. 25 A. Otherwise,

use a separate external fuse: 25 A.

Power supply and DC link circuit connection

The connections for the logic voltage supply, the power voltage supply and the

link circuit are not protected against wiring errors. The reversal of the connections

results in a device defect during switch-on.

With cross-wiring, observe the polarity of the DC link connection on all devices.

NOTICE

Overvoltage due to asymmetrical mains load

If the neutral conductor has to be disconnected when the device is switched

on and off, the device can be damaged by overvoltage due to an asymmetrical

network load.

• Design the mains connection with fuse and main switch so that the neutral

conductor is always switched on early and switched off later.