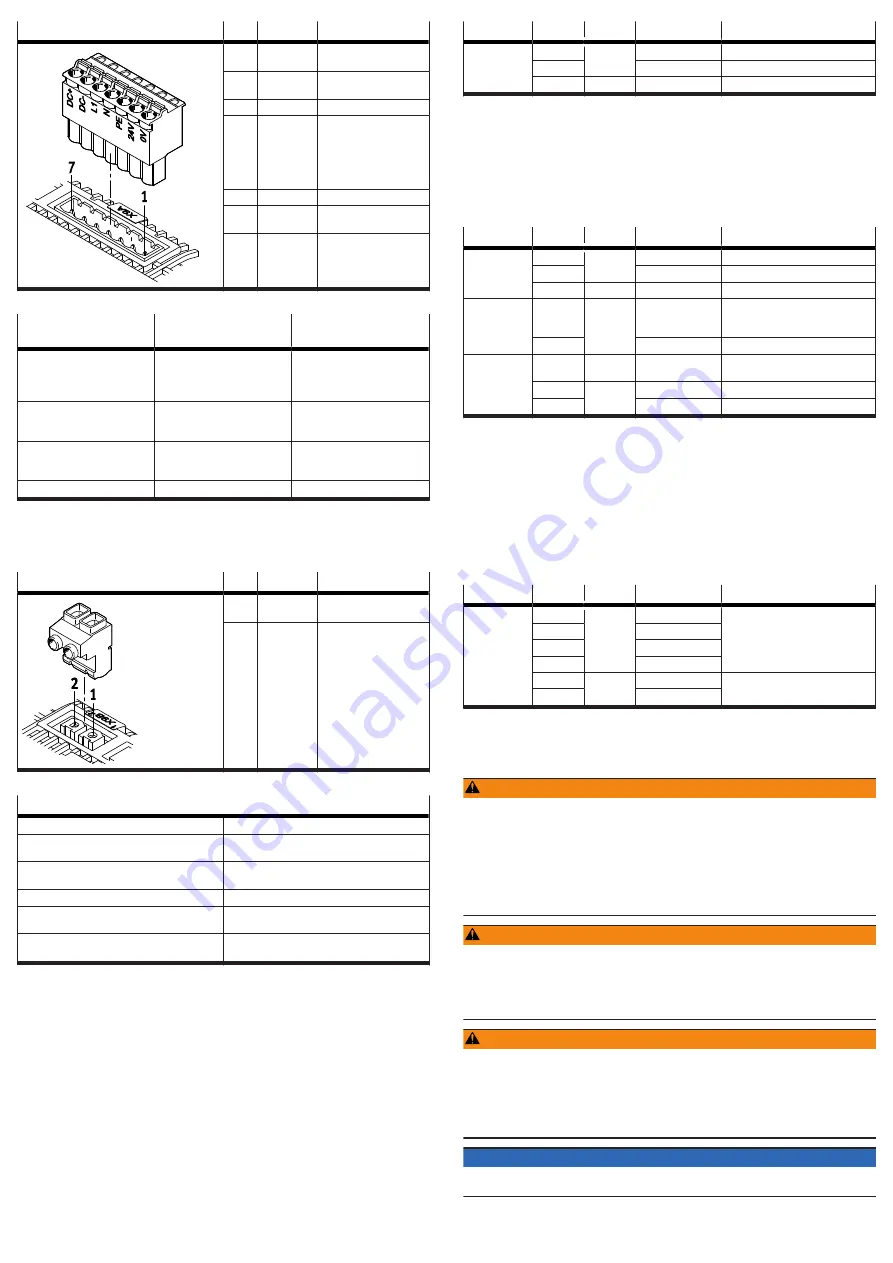

[X9A]

Pin

Function

Description

7

DC+

DC link circuit positive

potential

6

DC-

DC link circuit negative

potential

5

L1

Mains supply phase L1

4

N

For 1-phase mains con-

nection: mains supply

neutral conductor

For 2-phase mains con-

nection: mains supply

phase L2

3

PE

Protective earthing

2

24 V

Positive potential of the

24 V logic voltage

1

0 V

Reference potential of

the 24 V logic voltage

Tab. 37: Power supply and DC link circuit connection

Requirements for the

connecting cable

Single device

Device compound

Number of insulated wires and

shielding

5 insulated wires, unshielded

Without DC link coupling:

5 wires, unshielded

With DC link coupling: 7 wires,

unshielded

Min. conductor cross section

including wire end sleeve with

plastic sleeve

0.5 mm

2

1 mm

2

Max. conductor cross section

including wire end sleeve with

plastic sleeve

2.5 mm

2

2.5 mm

2

Max. length

2 m

£

0.5 m

Tab. 38: Requirements for the connecting cable

7.10.2

[X9B], connection for braking resistor

The connection [X9B] is located on the top of the device. The internal braking

resistor or a suitable external braking resistor is attached to the connection [X9B].

[X9B]

Pin

Function

Description

2

BR+Ch

Braking resistor positive

connection

1

BR-Ch

Braking resistor negative

connection

Tab. 39: Connection for the braking resistor

Requirements for the connecting cables of external braking resistors

Number of insulated wires and shielding

2 wires, shielded

Min. conductor cross section incl. wire end

sleeve with plastic sleeve

0.25 mm

2

Max. conductor cross section incl. plastic wire

end sleeve

2.5 mm

2

Max. cable length

2 m

Wiring

inside the control cabinet, shield connected to

PE

Tightening torque of the screw terminals on the

mating plug GIC 2.5 HCV/2-ST-7.62

0.5 … 0.6 Nm

1)

1) Specification of the manufacturer at the time the documentation was approved

Tab. 40: Requirements for the connecting cable

Selection of suitable braking resistors

Information on selecting suitable braking resistors

è

Manual Assembly, Installa-

tion.

7.11

Cross-wiring

Cross-wiring makes it possible to set up a device compound consisting of up to 10

servo drives CMMT-AS. The different cross-wiring options are as follows:

–

Cross-wiring of I/O signals at the connection [X1A]

–

Cross-wiring of the mains and logic voltage supply without DC link coupling

–

Cross-wiring of the mains and logic voltage supply with DC link coupling

Information on cross-wiring

è

Manual Assembly, Installation and Manual Safety

sub-function.

7.12

STO installation

Inputs and outputs for the safety sub-function STO

The 2-channel request for the safety sub-function is made via the digital inputs

#STO-A and #STO-B. The STA diagnostic output indicates whether the safe status

has been reached for the safety sub-function STO.

Connection Pin

Type

Identifier

Function

[X1A]

X1A.11

DIN

#STO-B

Safe torque off, channel B

X1A.12

#STO-A

Safe torque off, channel A

X1A.22

DOUT

STA

Safe torque off acknowledge

Tab. 41: Inputs and outputs for the safety sub-function STO

7.13

SBC installation

Inputs and outputs for the safety sub-function SBC

The 2-channel request for the safety sub-function is made via the digital inputs

#SBC-A and #SBC-B at the connection [X1A]. The SBA diagnostic output indicates

whether the safe status has been reached for the safety sub-function SBC. The

holding brake is connected via the connection [X6B]. The external clamping unit is

connected via the connection [X1C].

Connection Pin

Type

Identifier

Function

[X1A]

X1A.9

DIN

#SBC-B

Safe brake control, channel B

X1A.10

#SBC-A

Safe brake control, channel A

X1A.21

DOUT

SBA

Safe brake control acknowledge

[X1C]

X1C.1

DOUT

BR-EXT

Output for connection of an

external clamping unit (high-side

switch)

X1C.5

GND

Reference potential (ground)

[X6B]

X6B.1

–

FE

Functional earth connected to pro-

tective earth

X6B.2

OUT

BR+

Holding brake (positive potential)

X6B.3

BR–

Holding brake (negative potential)

Tab. 42: Inputs and outputs for the SBC safety sub-function

7.14

SS1 installation

Inputs and outputs for the safety sub-function SS1

The safety sub-function SS1 is wired like the safety sub-function STO but is

supplemented by the functional input CTRL-EN so that the braking ramp can be

activated by the safety relay unit.

7.15

Installation for operation without safety sub-function

Minimum wiring for operation without safety sub-function

For operation without the safety sub-function, wire inputs X1A.9 to X1A.12 as

follows:

Connection Pin

Type

Identifier

Function

[X1A]

X1A.9

DIN

#SBC-B

Supplies each one with 24 V

X1A.10

#SBC-A

X1A.11

#STO-B

X1A.12

#STO-A

X1A.21

DOUT

SBA

Do not connect

X1A.22

STA

Tab. 43: Wiring of inputs and outputs without safety sub-function

8

Commissioning

8.1

Safety

WARNING

Risk of injury from electric shock in the event of incomplete insulation at the

power connections [X6A], [X9A] and [X9B].

Before operating, plugging in or unplugging the operator unit CDSB or a con-

nector from a hot-plug-capable interface, the following points must be fulfilled:

• The conducting lines at the device are completely insulated.

• The protective earthing (PE) and the shield connection are correctly connected

to the device.

• The housing is free of damage.

WARNING

Severe, irreversible injuries from accidental movements of the connected

actuator technology.

Unintentional movements of the connected actuator technology can result from

exchanging the connecting cables of a servo drive or between servo drives.

• Before commissioning: All cables must be correctly assigned and connected.

WARNING

Risk of injury from electric shock.

Contact with live parts at the power connections [X6A], [X9A] and [X9B] can result

in severe injuries or death.

• Do not pull out power supply plugs while live.

• Before touching, wait at least 5 minutes after switching off the load voltage to

allow the intermediate circuit to discharge.

NOTICE

During commissioning: Keep the range of movement of the connected actuators

clear, so that no persons are endangered.