1

2

3

4

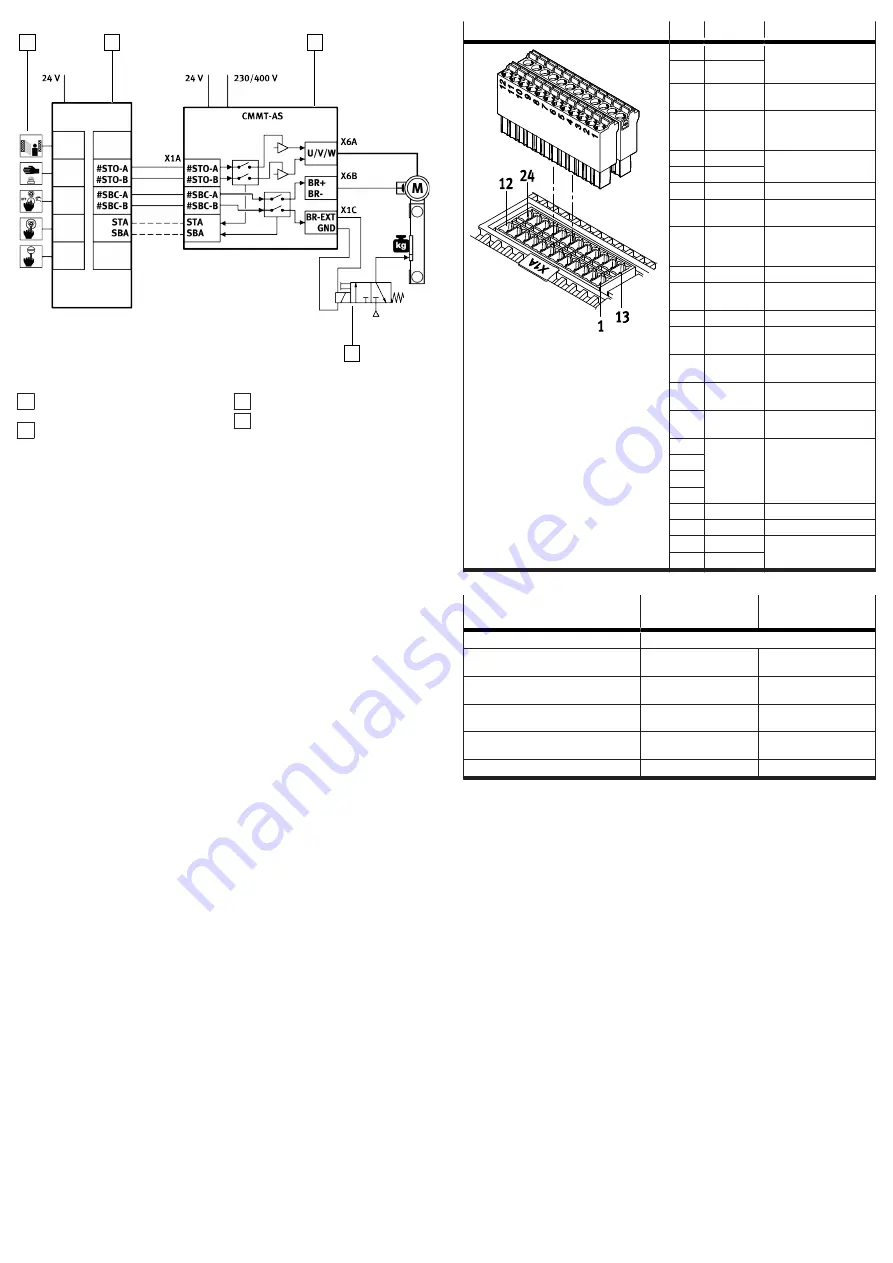

Fig. 8: SBC sample circuit

1 Input device for safety request

(e.g. light curtain)

2 Safety relay unit

3 Servo drive CMMT-AS

4 Control (here solenoid valve

example) of the clamping unit

Information on the sample circuit

The safety request is passed on to the servo drive on 2 channels via the inputs

#SBC-A and #SBC-B at the connection [X1A].

–

The request via the input #SBC-A switches off power to the signals BR+ and BR-

at the connection [X6B]. This de-energises and closes the holding brake.

–

The request via the input #SBC-B switches off power to the signal BR-EXT at the

connection [X1C]. This shuts off power to the control of the external clamping

unit. The clamping unit closes.

–

The safety relay unit monitors the SBA diagnostic output and checks whether

the safe status has been reached for the safety sub-function SBC.

7.8

Interfaces

Observe the requirements for mating plugs

è

Manual Assembly, Installation.

7.8.1

[X1A], inputs and outputs for the higher-order PLC

The I/O interface [X1A] is located on the top of the device. This interface offers

access to functional and safety-related inputs and outputs of the device. These

include, for example:

–

Digital inputs for 24 V level (PNP logic)

–

Digital outputs for 24 V level (PNP logic)

–

Signal contact for safety chain (RDY-C1, RDY-C2)

–

Differential analogue input ±10 V control voltage

The inputs and outputs of this I/O interface are used for coupling to a higher-

order PLC. The safety-related inputs and outputs are connected to a safety relay

unit.

[X1A]

Pin

Function

Description

24

RDY-C1

Normally open contact:

ready for operation mes-

sage (Ready)

23

RDY-C2

22

STA

Diagnostic output Safe

torque off acknowledge

21

SBA

Diagnostic output Safe

brake control acknowl-

edge

20

–

reserved, do not connect

19

–

18

SIN4

Release brake request

17

GND

Reference potential

(ground)

16

TRG0

fast output for triggering

external components,

channel 0

15

TRG1

like TRG0, but channel 1

14

CAP0

fast input for position

detection, channel 0

13

CAP1

like CAP0, but channel 1

12

#STO-A

Control input Safe torque

off, channel A

11

#STO-B

Control input Safe torque

off, channel B

10

#SBC-A

Control input Safe brake

control, channel A

9

#SBC-B

Control input Safe brake

control, channel B

8

–

reserved, do not connect

7

6

5

4

ERR-RST

Error acknowledgement

3

CTRL-EN

Power stage enable

2

AIN0

Differential analogue

input

1

#AIN0

Tab. 16: Inputs and outputs for the higher-order PLC with the CMMT-AS-...-S1

Requirements for the connecting

cable

Single device

Device compound

Shielding

Unshielded

Min. conductor cross section incl.

wire end sleeve with plastic sleeve

0.25 mm

2

–

Max. conductor cross section incl. plastic

wire end sleeve

0.75 mm

2

–

Min. conductor cross section incl. double

wire end sleeve with plastic sleeve

–

0.25 mm

2

Max. conductor cross section incl. double

wire end sleeve with plastic sleeve

–

0.5 mm

2

Max. length

3 m

0.5 m

Tab. 17: Requirements for the connecting cable

7.8.2

[X1C], inputs and outputs for the axis

The I/O interface [X1C] is located on the front of the device. This interface makes

functional and safety-related inputs and outputs available for components on the

axis. Output BR-EXT is used in conjunction with the safety sub-function Safe brake

control

è

Manual Safety sub-function.