Functional characteristics

MIG/MAG welding

18

099-0M37XM-EW501

16.07.2018

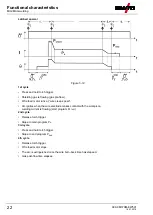

Display

Setting/selection

Correction of arc length in start program P

START

Slope time of start program P

START

to main program P

A

Slope time of main program P

A

to end program P

END

End-crater current

Setting range in percent: depending on main current

Setting range, absolute: Imin to Imax.

Correction of arc length in end program P

END

Burn-back time

> see 5.2.2.1 chapter

• ---------- Increase value > increase wire burn-back

• ---------- Decrease value > decrease wire burn-back

5.2.2.1 Burn-back

The wire burn-back parameter prevents the sticking of the wire electrode in the weld pool or at the contact

tip at the end of the welding process. The value is optimally preset for a variety of applications (but can be

adjusted if necessary). The adjustable value stands for the time until the power source switches off the

welding current after the welding process has been stopped.

Welding wire behaviour

Setting instructions

Wire electrode is sticking in the weld pool.

Increase value

Wire electrode is sticking on the contact tip or large ball

formation on the wire electrode

Reduce value

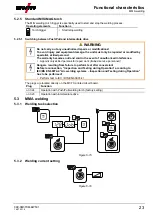

5.2.3

Program sequence

Certain materials require special functions for reliable and high-quality welding. In this case, the special

latched mode is used with the following programs:

• Start program P

START

(avoidance of cold welds at start of seam)

• Main program P

A

(continuous welding)

• End program P

END

)

(avoidance of end-craters by targeted heat reduction)

The programs contain parameters such as wire feed speed (operating point), correction of arc length,

slope times, program duration, etc.

Figure 5-11

5.2.4

Operating modes (functional sequences)

5.2.4.1 Explanation of signs and functions

Symbol

Meaning

Press torch trigger

Release torch trigger