4

ENVIRO V. X.XX

TOTAL: XXXX.XX Hours

control SyStem oPeratIon

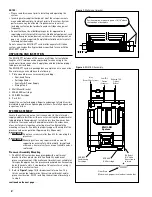

The ENVI-RO system includes a micro-processor based control

system that monitors system conditions and controls the system

operation. A digital display panel provides operational information

and 4 buttons provide operator access. To follow is a list of modes

and a description of each function. Use this as a guide during start-

up, normal operation and when service is required.

operational mode

maIn Screen VIeW -

•

When the system is in normal operation

and not operating in any of the following operational modes,

the panel will display the system identification with software

version and total run hours since start-up, or last reset.

PreSSurIZe -

•

When pressure in the storage tank drops

below the pressure switch “on” setting, the system will

start processing water and refill the storage tank. Once the

pressure in the storage tank rises above the pressure switch

“off” setting, the system will stop. Run time in seconds will be

displayed.

fluSHIng -

•

If the ENVI-RO System remains idle for

the programmed length of time, the control system will

automatically go into FLUSHING mode. During this time, there

will be flow to drain (reject). Remaining flush time in seconds

will be displayed.

refIll -

•

At the end of FLUSHING, or if pressure drops too low in

the storage tank during FLUSHING, the control will enter REFILL

mode. Run time in seconds will be displayed.

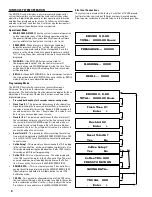

Programming mode

The ENVI-RO Controller has several user accessible menu’s.

This menu “loop” allows for adjustment of several variable

parameters. The Controller has 4 buttons below the display for these

adjustments. Description of the button functions are shown in the

digital display area.

Press and hold any key for 3 seconds to enter set-up mode.

•

flush time X1 -

•

This parameter determines the flush duration.

Upon determining the recovery and reject flow, a time value in

seconds is entered for this setting. Range is 0-995 seconds in 5

second increments. Use the +/- keys to adjust this value. Press

Enter to save value and go to next screen.

flush Int X2 -

•

This parameter determines the flush interval. If

the system does not process water for the time value selected,

the system will enter FLUSHING mode. A time value in hours

is entered for this setting. Range is 0.5 to 10 hours in 0.5 hour

increments. Use the +/- keys to adjust this value. Press Enter to

save value and go to next screen.

reset total Hr? -

•

This parameter allows resetting the total run

time, which is displayed in the MAIN SCREEN VIEW. Press YES

to reset, NO to NOT reset. Controller saves selection and goes

to next screen.

coffee Setup? -

•

This parameter allows viewing the TDS reading

in the coffee outlet line, with a very frequent up-date rate. Use

this mode when adjusting the blend valves. Select YES to enter

this mode, and NO to exit programming.

coffee tdS: -

•

This is a view only screen. The value displayed

is the TDS level of the water in the Coffee outlet line. The most

accurate readings are attained by having flow on the Coffee

line. Press any key to return to the MAIN SCREEN VIEW.

SaVIng data... -

•

This is a view only screen. The controller is

saving the settings and returning to the MAIN SCREEN VIEW.

If desired, press and hold either middle button to enter TDS

Calibration mode.

tdS cal -

•

This parameter allows adjustment of the TDS value

the controller will display. Use this mode to calibrate the system

with a calibration solution. Use the +/- keys to adjust this value.

Press Enter to save and return to the MAIN SCREEN VIEW.

Flush Int X2

- Enter +

Reset Total Hr?

Yes No

Coffee Setup?

Yes No

Coffee TDS: XXX

PRESS TO RETURN

SAVING DATA...

TDS CAL XXX

- Enter +

PRESSURIZE... XXXXX

REFILL... XXXX

FLUSHING... XXXX

Flush Time X1

- Enter +

yes no

ENVIRO V. X.XX

TOTAL: XXXX.XX Hours

electrical connections

The system is pre-wired at the factory. Verify that a 115 VAC ground

fault protected circuit rated at 15 Amps minimum is located nearby.

Plug-in power cord when instructed to do so in the following section.

Содержание ENVI-RO

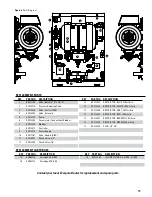

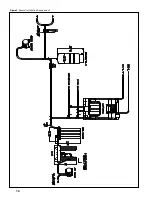

Страница 13: ...13 13 6 346 23 583 406 16 32 Side View Front View Top View 813 Figure 7 Dimensional Drawing...

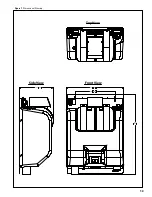

Страница 14: ...14 Figure 8 General Installation Arrangement...

Страница 15: ...15 NOTES...