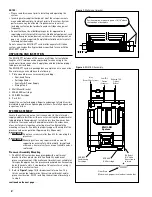

figure 4.

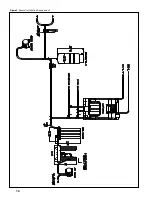

Reject Y-Connector Detail

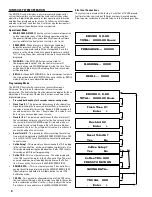

figure 3.

Inlet and Outlet Connections

3

Refer to

3.

figure 1

for mounting bracket details. Position the top

row of holes 1-9/16" inches below the top of the processor when

installed. Install the wall mount bracket to a suitable vertical

surface. Use no less than 4 - #12 fasteners to secure the bracket

to the surface.

Prepare to attach the processor to the wall mount bracket.

4.

Lift the processor and “hook” the metal lip of the processor

backplate over the top edge of the wall mount bracket.

Go to step 6.

Measure and install 2 - #12 fasteners on 16" centers to engage

5.

the top edge of the processor backplate - leave 1/4" gap. Lift

the processor and “hook” the key-hole slots on the processor

backplate. Tighten the 2 fasteners.

Install 2 - #12 minimum fasteners in the 2" wide slots along the

6.

bottom edge of the processor backplate.

Piping/tubing connections

Refer to

1.

figure 2

and the drawing on Page 14 for general views

of the piping, with a description of major components and

connection points. These major components and connections

will be referred to in the following steps.

A parts kit has been provided, which includes valves and tees to

2.

configure a system by-pass. Assemble the parts to the system

using the example shown in

figure 3

.

Prepare the plumbing to accept the RO system.

3.

note:

The product water tubing/piping and associated fittings

connecting the RO product outlet to the equipment being

serviced should be food grade material that meets NSF

Standard 51 or 61 with a minimum pressure rating of 100-PSI.

The product water may react with metal piping, creating a

corrosive condition, in addition to imparting an objectionable

taste. Plastic pipe or reinforced tubing are generally very

good choices for RO water distribution materials. The size of

the product water tubing/piping should be 3/8" ID minimum.

Distances of 25 feet or greater from the RO to the equipment

being serviced should be 1/2" ID minimum.

Shut-off the supply of water to the existing filtration system, and

4.

relieve pressure. Connect a line from the treated water outlet of

the filtration system to the inlet of the ENVI-RO system.

Connect the appropriate size and type of tubing/piping and

5.

associated fittings to the corresponding ENVI-RO outlet

connection. Route the line(s) to the equipment being serviced

(i.e.; espresso, coffee, etc.). Close the inlet, outlet and by-pass

valves. Apply pressure to the existing filtration system and place

it back into service.

Check the

6.

storage tank pre-charge pressure. It should only be

checked and adjusted when the storage tank is empty. A 30 psi

pre-charge pressure is required.

Connect a 3/8" OD tube to the reject Y-connector (labeled

7.

WASTE) located in lower right corner of processor. Route the

other end of the tubing to a drain nearby, securing it properly.

Allow an air gap at the drain, following any applicable local and

national codes. See

figures 2 and 4

.

WARNING

Refer to “

Reject to Drain, Maximum”

under

RO

Production

in the Performance Table (page 8) to

determine the maximum gallon per minute waste

flow rate. Verify drain has ample capacity for this

waste flow, plus all other sources of waste flow

sharing this drain.

Locate the needle valve from the parts kit. Attach a short section

8.

of 3/8" tubing to this valve.

note:

This assembly will be used to adjust the system recovery in

the following section, then removed.

Remove the 3/8" tube from the reject Y-connector and install the

9.

needle assembly between the reject Y-connector and 3/8" tube.

Inlet

St

ea

me

r

co

ff

ee

Содержание ENVI-RO

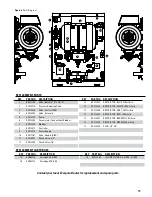

Страница 13: ...13 13 6 346 23 583 406 16 32 Side View Front View Top View 813 Figure 7 Dimensional Drawing...

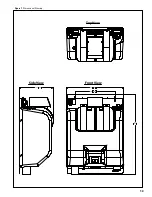

Страница 14: ...14 Figure 8 General Installation Arrangement...

Страница 15: ...15 NOTES...