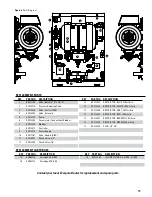

20.0 508

5.0 127

3.1 80

16X .33

THRU

8.4

17.8 452

16.6 422

15.4 391

14.2 361

4.2 107

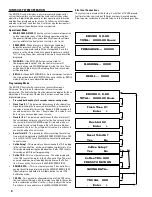

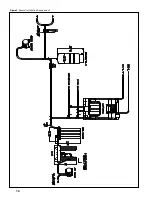

Low TDS

Outlet

(Steamer)

Inlet

(From Filter System)

Reduced TDS

Outlet

(Coffee)

ENVI-RO

System

2SR-BW

Conditioning

Cartridge

MR-600

RO Cartridge

RO Reject

(3/8" John

Guest) route

to drain

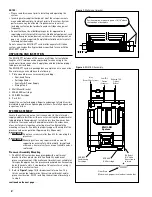

figure 1.

Wall mount bracket.

figure 2.

ENVI-RO Assembly.

2

noteS:

Please read this manual prior to installing and operating the

•

system.

Incoming water supplies that do not meet these requirements

•

may need additional pre-treatment prior to the system. System

performance may be affected if requirements are not met,

including system output production and cartridge change-out

frequency.

Consult with your local building inspector for approval and

•

required permits to install this system. Additional equipment, such

as back-flow prevention devices, seismic restraint equipment, air

gaps, etc., may be required. Completed installation must meet all

local and national codes.

Do not connect the ENVI-RO™ system after any water filtration

system, unless specifically provided or specified for use with the

ENVI-RO™ system.

unPackIng and InSPectIon

The ENVI-RO™ includes all the necessary fittings for installation.

Lengths of 3/8" tubing have been provided for connecting to the

wastewater/drain connection. Supply lines and distribution piping/

tubing are not included.

The ENVI-RO™ system is packaged as a complete unit in one carton.

At a minimum, you should have the following:

Plate mounted processor assembly including:

1.

Dual-head Pump

•

Cartridge Heads

•

Controller & Power Supply

•

Storage Tank

•

Wall Mount Bracket

2.

MR-600 RO cartridge

3.

2SR-BW Cartridge

4.

Parts Kit

5.

Inspect the carton for damage. Report any damage to freight carrier

immediately and retain all packaging materials. Carefully unpack and

inspect each item.

SyStem aSSembly

Locate the system in an area that is convenient to the inlet water

supply and drain facilities, with access for routing the product water

tubing/piping to the equipment. Install in a dry location, away from

all forms of corrosive and/or flammable materials. Consider ease

of access for servicing when selecting a location. Evaluate the

mounting surface for its ability to properly support the weight of the

processor when in operation (Approximately 90 pounds).

WARNING

Do not use screws smaller than #12 for mounting the

processor.

WARNING

Mounting surface may require reinforcement to

support processor safely. Hollow walls, drywall and

other non-structural surfaces are not suitable unless

reinforced.

Processor assembly mounting

The ENVI-RO system has been provided with a wall mount

1.

bracket to allow greater installation flexibility and ease of

processor placement. If the wall mount bracket is not suitable for

this specific application, the processor backplate has 4 mounting

holes (2 keyhole slots, 2 standard) on 16" centers for securing it

directly to a vertical surface.

Refer to

2.

figure 7

(page 13) for dimensional information. Use

this as your guide to determine the wall mount bracket and/or

processor location. If NOT installing the wall mount bracket go

to step 5.

continued on the next page . . .

Floor Drain

Maintain air-gap per local and national codes

Position top line of mounting holes 1-9/16” above

the top edge of backplate

Содержание ENVI-RO

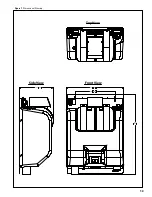

Страница 13: ...13 13 6 346 23 583 406 16 32 Side View Front View Top View 813 Figure 7 Dimensional Drawing...

Страница 14: ...14 Figure 8 General Installation Arrangement...

Страница 15: ...15 NOTES...