-- 20 --

bu12d04a

The next line in the main menu is AUXILIARY FUNCTIONS (OPTIONS). You can

read more about these functions in the section ”AUXILIARY FUNCTIONS” under

section

9.

ESAB LUD 450

PROCESS:

MIG

METHOD:

DIP/SPRAY

WIRE TYPE:

Metal cored Fe

SHIELDING GAS:

Ar+8%CO2

WIRE DIAMETER :

0.040” (1.0mm)

AUXILIARY FUNCTIONS

"

SET

MEASURE

MEMORY

FAST

MODE

ENTER

2.8.2

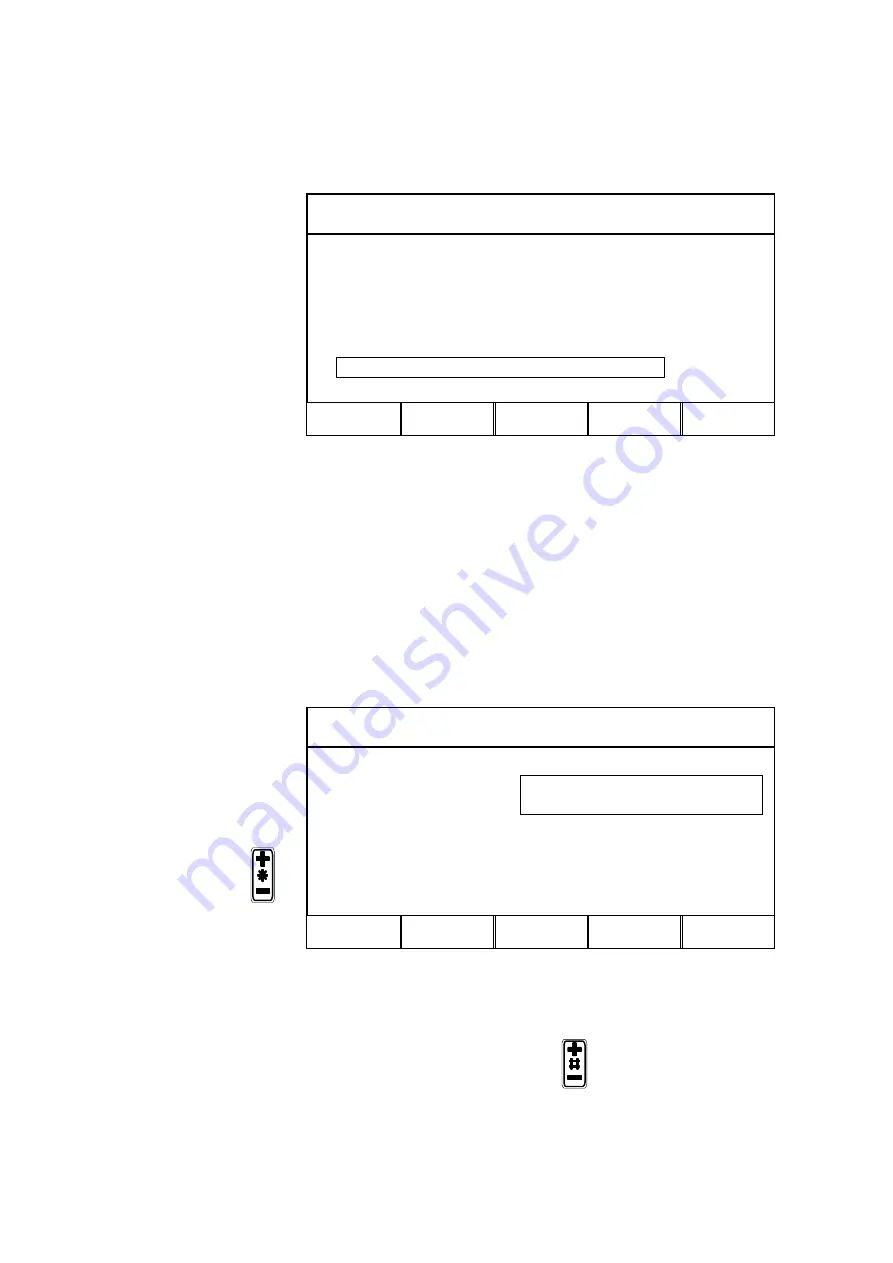

Weld Data Settings

From the settings menu, you can set values for various welding parameters, such as

voltage and wire feed speed. By activating the synergic function, many of these

settings will be handled by a microprocessor.

We begin by pressing the MENU button to display the main menu. Press the SET

button to view the settings menu. We’ll now make the following settings:

S

WIRE FEED SPEED = 393 in/min (10.0 m/min).

Wire Feed Speed

WELD PARAMETERS

Position the cursor

on the line

WIRE SPEED.

Set it to 393 in/min

(10.0 m/min) using:

VOLTAGE:

# 29.0 (+0.0) V

WIRE SPEED:

*

393 in/min (10.0 m/min)

INDUCTANCE:

80 %

SYNERGIC MODE

ON

START DATA . . .

STOP DATA . . . .

CRATR

FILL

HOT

START

4--

STROKE

QUIT

In the settings menu you can now also see the values that the microprocessor has

chosen for voltage and inductance.

The

voltage

parameter may also be adjusted if required.