Setup & Operation 2. Specifications

LS20 Rev.4

25

Item

LS20-804S

LS20-A04S

LS20-804C

LS20-A04C

Max.

motion range

Joint #1

±

132

deg

Joint #2

±

152 deg

Joint #3

420 mm

390 mm

Joint #4

±

360

deg

Max.

pulse range

Joint #1

−

152918 to 808278

Joint #2

±

345885

Joint #3

−

283853 to 0

−

263578 to 0

Joint #4

±

344064

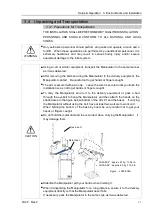

*1: In the case of PTP command.

Maximum operating speed for CP command is 2000 mm/s on horizontal plane.

*2: In the case where the center of gravity is at the center of Joint #4.

If the center of gravity is not at the center of Joint #4, set the parameter using Inertia command.

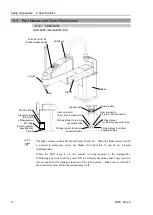

*3: The exhaust system in the Cleanroom-model Manipulator draws air from the base interior and arm cover

interior together.

A crack or other opening in the base unit can cause loss of negative air pressure in the outer part of the

arm, which can cause increased dust emission.

Do not remove the maintenance cover on the front of the base.

Seal the exhaust port and the exhaust tube with vinyl tape so that the joint is airtight.

If the exhaust flow is not sufficient, dust particle emission may exceed the specified maximum level.

Cleanliness level : Class ISO 4 (ISO14644-1)

Exhaust System

: Exhaust port diameter : Inner diameter: ø12 mm / Outer diameter: ø16 mm

Exhaust tube : Polyurethane tube

Outer diameter: ø12 mm (Inner diameter:ø8 mm) or

Inner diameter ø16mm

Recommended exhaust flow rate : approx. 1000 cm

3

/s (Normal)

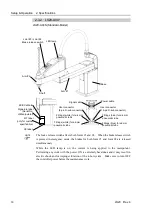

*4: Conditions of Manipulator during measurement as follows:

Operating conditions : Under rated load, 4-joints simultaneous motion, maximum speed, maximum

acceleration, and duty 50%.

Measurement point : Rear of the Manipulator, 1000 mm apart from the motion range, 50 mm above

the base-installed surface.

*5: In general use, Accel setting 100 is the optimum setting that maintains the balance of acceleration and

vibration when positioning. Although values larger than 100 can be set to Accel, it is recommended to

minimize the use of large values to necessary motions since operating the manipulator continuously with

the large Accel setting may shorten the product life remarkably.

Содержание LS20

Страница 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Страница 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Страница 8: ...vi LS20 Rev 4 ...

Страница 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Страница 14: ......

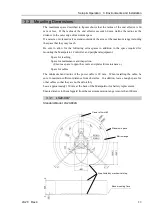

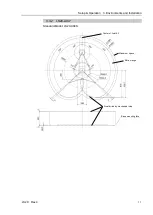

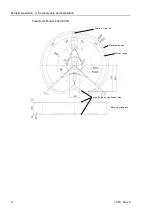

Страница 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Страница 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Страница 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Страница 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Страница 71: ...Maintenance This volume contains maintenance procedures with safety precautions for LS20 series Manipulators ...

Страница 72: ......

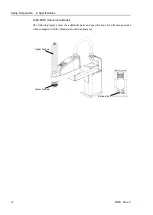

Страница 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Страница 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...