Modbus settings

Page 50

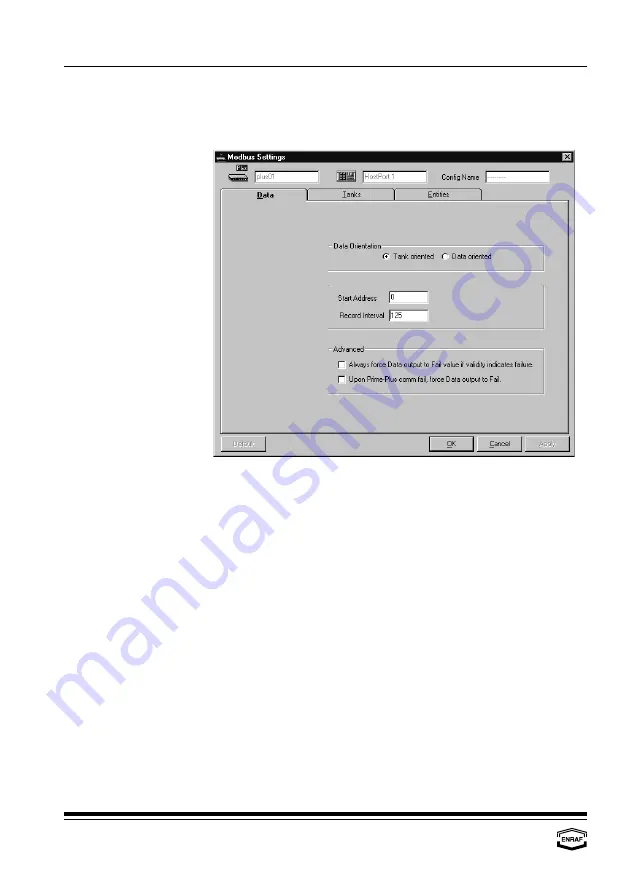

Modbus settings

Data

Data Orientation

Select:

Tank oriented (= data grouped by tank) or Data oriented

(= data grouped by entity)

Start address

Enter start address (default = 0)

Record interval

Enter the number of registers between tank records

(default = 0050 for the Plus/Prime)

Advanced

Always force Data output to Fail if validity indicates failure.

Select to force the modbus registers to FFFFF in case of invalid data.

If

not selected the last measured value will be stored

Upon Prime Plus comm.fail. Force data output to Fail

Select to force the modbus registers to FFFFF in case of invalid data.

If

not selected the last measured value will be stored

Содержание Ensite Pro

Страница 74: ...Help Page 74 Help Click on this icon for on line assistance ...

Страница 78: ...Notes Page 78 ...

Страница 79: ...Notes Instruction manual Ensite Pro Configuration Tool Page 79 ...