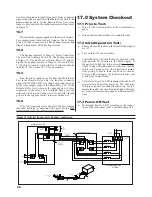

11.6

Route current transformer wires and the control cable

around the right side of the Data/Link PC Board and box

to avoid close proximity to high voltage wires. Current

transformer leads must enter the relay box in the Class 2

compartment.

12.0 Creating a Load

Schedule & Making

Load Assignments

The 9312 is shipped from the factory ready to operate

under the Combination Load Control Strategy with preset

8 and 5-minute Minimum On/Off-Times on Circuits 2 and

3. Changes in load control strategy, Minimum On/Off-

Times, and other system information may be made through

the front panel of the Control/Display Unit. However, all

components of the 9312 must fi rst be installed and verifi ed

operating properly as set forth in Section 17.

Caution: Ensure all circuits to be controlled are

turned off at the appropriate circuit breaker in the

circuit breaker panel before proceeding with any

wiring.

Warning:

When controlling heat pump and air

conditioning compressor loads, a Minimum Off-Time of

at least 4 minutes must be programmed. Minimum Off-

Times are available on all circuits. (Some manufacturer’s

may require longer Minimum Off-Times for compressor

protection. Check with manufacturer.) When installation is

complete Minimum On and Off-Times can be programmed

in Section 18.

12.1

Prepare a load schedule identifying which loads will

be connected to which circuits. The following are examples

only. Your application may be different and require a varia-

tion of these examples. Contact your Energy Sentry Dealer

for application assistance.

12.1.1

For Electric Baseboard Or Radiant Ceiling Heat

Homes:

Example Only

. It is recommended that for best results

with these types of heating systems, the loads be connected

as follows:

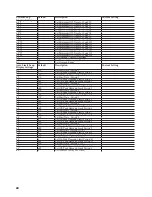

Example 1: Load Control Strategy: Combination

Circuit #

Load

Priority

1

Dryer

1

2

Hot Water Heater

2

3

Heat #1

3

4

Heat #2

3

5

Heat #3

3

6

Heat #4

3

7

Heat #5

3

8

Heat #6

3

12.1.2

For Homes With Heat Pumps Without Compressor

Connected

Example Only

. In some heating climates it may be

preferable not to connect the heat pump compressor to

the 9312. Check with your local utility and/or heating

contractor to determine whether your compressor should

be controlled. If you decide to control your compressor,

please refer to section 12.1.3. Electric forced air furnace

heat strips should be controlled. Electric furnaces usually

have from two to fi ve stages of heat which is controlled by

a “sequencer”. The sequencer usually uses a fi xed priority

scheme to turn on and off these heat strips as required.

Heat strips should be controlled individually with remote

relays on the 240 VAC line. (See Section 16). The follow-

ing general load schedule is typical of this application:

Example 2: Load Control Strategy: Fixed Priority

Circuit #

Load

Priority

1

Dryer

1

2

Heat #1 (1A)

2

3

Hot Water Heater 3

4

Heat #2 (1B)

4

5

Heat #3 (2A)

5

6

Heat #4 (2B)

6

7

Heat #5 (3A)

7

8

Heat #6 (3B)

8

This schedule may be altered as necessary to suit the

needs of the particular home and user. This is an example

only. For application assistance, contact your Energy

Sentry representative.

12.1.3

For Homes With Heat Pumps With Compressor Con-

nected:

Example Only

. When assigning loads for homes with

heat pumps or air conditioners with the 24VAC thermostat

control loops connected, thermostats must be connected to

Circuits 2 and 3 as discussed above.

Example 3: Load Control Strategy: Combination

Load

Circuit #

Schedule A

Priority

1

Dryer

1

2

Compressor A/C 2

3

Heat #1

3

4

Water Heater

3

5

Heat #2

4

6

Heat #3

5

7

Heat #4

6

8

Heat #5

7

22