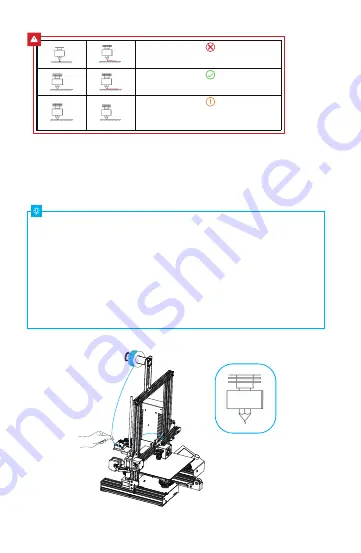

The nozzle is too far away from the platform,

and the filaments cannot stick to the platform.

The nozzle is too close to the platform, and

the filament is not extruded enough, which

may damage the platform.

The filament is evenly extruded and sticks to

the platform just right.

A.

In order to successfully load the filament, please trim the end of the filament at an angle of 45 degrees.

B.

Press the filament until it passes through the filament detection

hole. Then press and hold the extruder

handle to insert the filament into Teflon tube until it reaches t

he nozzle.

C.

Warm up the nozzle. If the filament flows out of the nozzle when

the temperature reaches the target value,

the filament is properly loaded.

7 Loading the Filament

Replacing the filament:

1.When the printer is not printing:

A.

Heat the nozzle to 185℃ or higher, wait for the filament in the

nozzle to soften. Then press and

hold the extrusion handle to quickly extract the filament to pre

vent it from clogging in the heat break.

B.

Place the new filament onto the rack and repeat the steps in Sec

tion 7: Loading the Filament.

2.When the printer is printing:

A.

Pause the printing. After the printer stops, press and hold the extrusion handle and quickly extract

the filament to prevent it from clogging in the heat break.

B.

Place the new filament onto the rack and press it through the fi

lament detector. Press and hold

the extrusion handle to insert the filament into the nozzle. Then push the filament to squeeze out the

residual filament in the nozzle and clean up the nozzle before r

esuming printing.