25

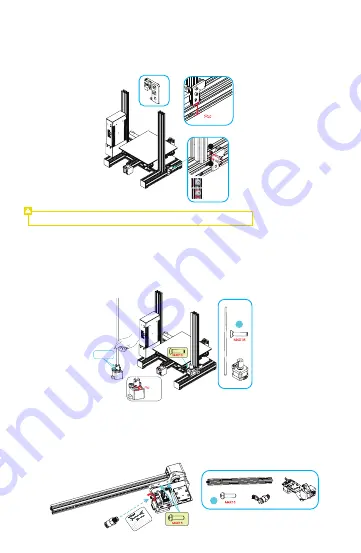

A.

Confirm that the distance between the bottom of the coupling and

the motor is 5 mm;

B.

Insert the screw rod into the coupling, confirm the screw reach

the bottom, and lock the screw with tools;

C.

Fix the motor and screw to the back of the left profile of the Z

-axis with two M4x18 hexagon socket

countersunk head screws.

Note: To lock the ship-type nut, it must be perpendicular to th

e profile slot.

Install the Z-axis limit switch

Secure the Z-axis limit switch to the outside of the left profile of the Z-axis with 2 x M5*8 hexagon socket

button head screws and 2 ship-type nuts at a distance of 32 mm from the lowest part of the bottom

profile.

Install the extrusion kit

A.

Lock and secure the extrusion kit to the X-axis profile with two

M4X16 hexagonal button head spring

washer combination screws;

B.

Then fix the pneumatic coupling to the extrusion kit with an ope

n-end spanner, and tighten it in the

direction shown in the figure.

Install the Z-axis motor and screw rod

a

b

a:Fasten it

b:Then

embed it

Auto leveling, no installation needed

5mm

26

32mm