28

29

24

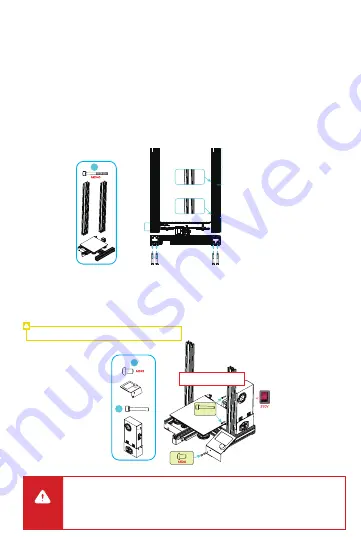

5 Install the Printer

Install the Z-axis profile

Shorter

Shorter

Longer

A.

Expose the right profile of the base component to the table surf

ace by about 35 mm, so that the mounting

hole is exposed to the table platform;

B.

Place the right profile of the Z-axis onto the base slot and pre

-lock it with two M5x45 hexagonal cylindrical

head spring washer combination screws aligned with the holes from the bottom upwards;

C.

Rotate the base component by 180° so that the left profile of th

e base component is exposed to the table

top by 35 mm, then place the left profile of the Z-axis onto the base slot, pre-lock the left profile with two

M5x45 hexagonal cylindrical head spring washer combination screws aligned with the holes from the bottom

upwards, and then tighten the screws;

D.

Rotate the base component by 180° again, and tighten the screw on the right side.

Installation of power supply components and display

A.

Fix the power supply component to the right profile of the Z-axi

s with two M4x20 hexagonal cylindrical head

spring washer combination screws; note that the DIP switch faces backwards by this moment;

B.

Fix the display to the right profile of the base with two M5*8 h

exagonal button head screws.

Note: Adjust the mains voltage to suit your region.

C a u t i o n

●

Please ensure the correct position for the power supply switch and mains before supply

connection, in order to avoid damage to the device.

●

If the mains is between 200V and 240V, please select the 230V for the power supply

switch (230V by default).

●

If the mains between 100V and 120V, please select the 115V for the power supply switch.

M4X20

M4X20

Choose 230V or 115V based

on local voltage