E-mail: [email protected]

Made in Rome, New York, USA

6

SUPERHEA

T CHARGING CHAR

T

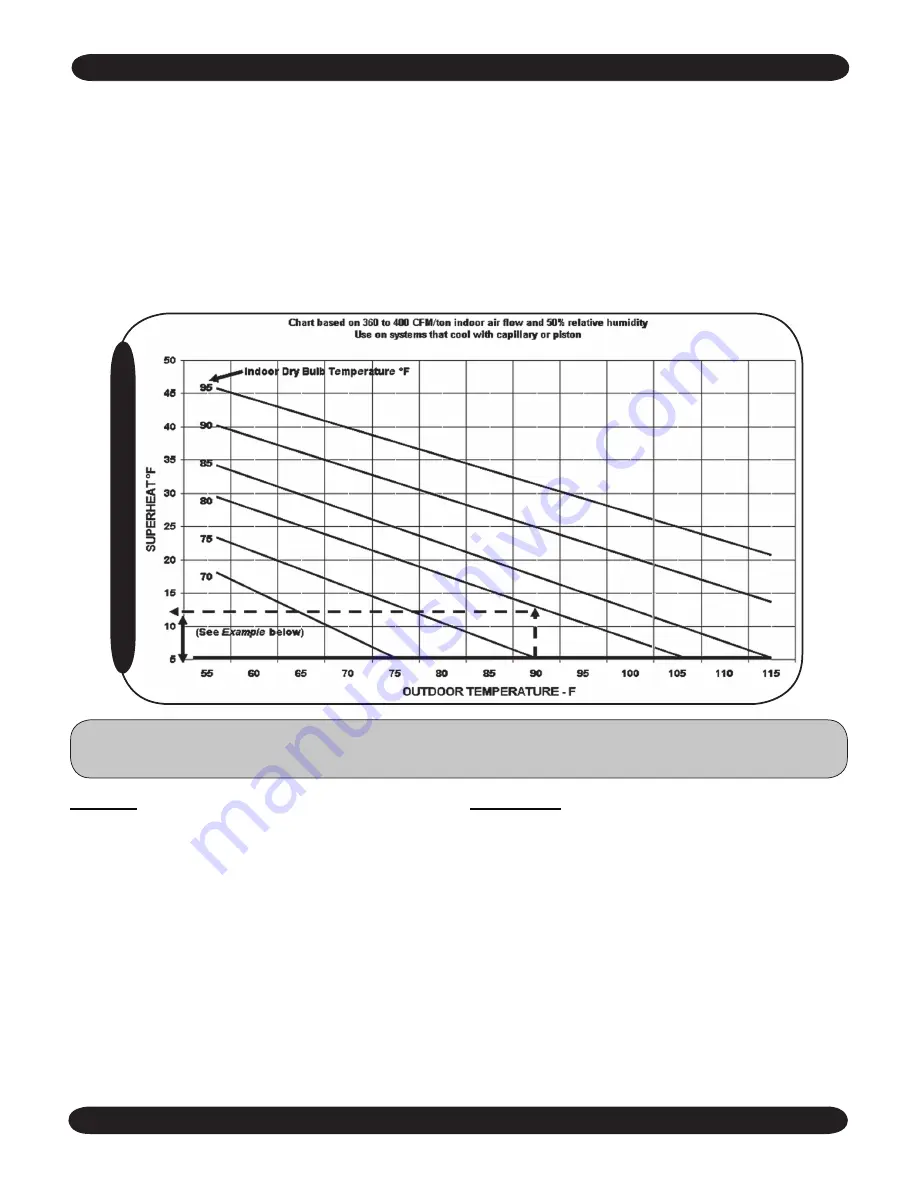

FIELD CHARGING

Example:

1. Suction pressure is 65 psi. which equals 38

°

F on

The

R-22 Scale of the Low-Side Gauge.

2. Suction line temperature taken at the unit is 70

°

F. 70

°

F minus 38

°

F equals 32

°

F superheat.

3. Outdoor temperature is 90

°

F; indoor temperature is

80

°

F.

4. Intersection of the indoor-temperature and outdoor-

temperature lines occur on the 12

°

F superheat line.

5. Add charge to obtain 12

°

F superheat.

Instructions:

1. Measure suction pressure and determine evaporator-

refrigerant temperature on R-22 scale of low-side

gauge.

2. Measure suction-line temperature on suction line of

the unit.

3. Measure outdoor and indoor temperatures.

4. Determine from the table what the superheat should

be for the indoor and outdoor temperatures. (Example

indicates 12

°

F superheat.)

5. Adjust charge if needed. Be sure unit is running at

stabilized condition.

The use of the superheat method is highly recommended

for field charging or checking the existing refrigerant

charge in a system. Because each installation is different

in terms of indoor air flow, refrigerant line length, etc.., the

factory charge may not be correct for every application.

To assure the best performance from the air-conditioner,

the refrigerant charge should be checked and adjusted, if

need be, on each installation.

For proper superheat readings, a standard low-side

refrigerant gauge and an accurate thermometer is

needed. A mercury or stem-type thermometer is not

adequate for suction-line temperatures. We recommend

electric thermocouple thermometers (available at most

refrigeration wholesalers); however an accurate remote-

bulb thermometer can be used. When measuring the line

temperature, be sure the thermometer is well installed to

assure accurate measurements. The chart below gives

superheat values at various outdoor temperatures. Allow at

least 5 minutes running time between charge adjustments

for the unit to stabilize.

Note:

If operating superheat is more than 5

°

F above the chart value, add refrigerant. If below the chart

value remove refrigerant. If below the limit line, remove refrigerant.