Introduction

Type Dosaodor-D is a computerized odorant injection

system for natural gas using patented solenoid

injector technology that eliminates the need for

plunger pumps.

The solenoid injectors provide odorant injection

accuracy to be maintained over the entire flow range

of the system, approaching infinite turn down.

Automatic calibration during operation adjusts for any

changes in mechanical components and also detects

failures for alarming. Report by exception alarming is

a configurable option.

The system can also be configured to use

redundant injectors and/or an emergency backup or

bypass absorption system.

Real time and historical data can be read locally or

remotely by a laptop computer using ROCLINK 800

configuration software or remotely using third party

SCADA products utilizing ROC or Modbus protocol.

ROCLINK 800 software is available for complete

configuration and operation of the system including:

• Display of real time and historical data

• Configuration of alarms

• Archival of historical data

Benefits

• Uniform distribution of odorant due to frequent

smaller injections and enhanced absorption from

the wick insertion.

• High turndown ratio. For example, one specific

configuration would evenly distribute odorant at

flow rates from 2000 to 1,200,000 SCFH / 53.6 to

32,160 Nm

3

/h without mechanical adjustment.

• Automatic calibration of injection system during

normal operation ensuring consistent odorization.

• Environmentally friendly with no venting of gas or

odorant while operating.

• Extremely low maintenance cost.

• Variety of redundancy and backup options for

reliable odorization.

• User friendly configuration software.

• Standard and scalable hardware platform that

supports additional station I/O for AGA flow

calculations and PID control algorithms.

Operation

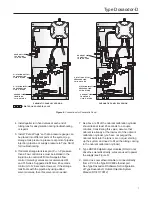

The Type Dosaodor-D odorant injection system

operates on the basic principle of a fixed differential

pressure and orifice used to measure a non-

compressible fluid.

Fixed differential pressure is maintained using double

cut regulation by fixed differential pressure regulators

(Type SA/2 regulators) which reference P

2

and reduce

the inlet pressure of a regulating station to P

2

+ ∆P.

∆P

min

= 8.7 psi / 0.60 bar, ∆P

max

= 21.7 psi / 1.5 bar

(an alternate high-pressure source can be used). This

pressure loading of the odorant calibration cylinder

filled with odorant is used to inject liquid odorant into

the downstream pipeline through an on/off valve (the

fixed orifice

1

) with a known flow coefficient that is

controlled by the automated system. The objective of

the automated control system is to maintain an injection

rate specified by the user which is proportional to the

gas flow. Accuracy of injection is accomplished utilizing

relatively small injections which are automatically

resized over a wide range dependent upon variations

in the gas flow. This results in a turn down ratio for

the system that can exceed 500:1 (the addition of a

simple bypass system utilizing the odorant storage

tank can allow the turn down ratio to approach infinity).

An odorant calibration cylinder with a fixed volume is

utilized to recalibrate the injection valve flow coefficient

each time the odorant calibration cylinder is refilled.

During the refill cycle the pressure used for injection is

relieved into the downstream pipeline which eliminates

venting of gas to atmosphere or an expansion tank.

Liquid odorant refill of the odorant calibration cylinder

is typically accomplished by using all or some part of

the P

2

+ ∆P pressure to load the odorant storage tank

thus pushing the liquid out of the tank and into the

odorant calibration cylinder, ∆P = 8.7 to 21.7 psi /

0.60 to 1.5 bar.

Since the unit uses only pressure for injection there

are few moving parts in the system resulting in very

little maintenance. Relatively low cost options for both

automated and emergency redundancy for odorization

are also available.

The gas flow rate is obtained through either a

corrected gas volume pulse input or an instantaneous

flow rate analog input (4 to 20 mA) signal. The gas

1. Although the valve orifice is fixed for a specific application the valve can be adjusted manually to accommodate flow rates as small as 2 MSCFH to over 33,000 MSCFH with one injector.

3

Type Dosaodor-D