Put the system in Manual mode to start the injection

(push Manual button).

In order to calibrate the injection solenoid valve, verify

from “Current Injection Data” the current Specific

Volume value related to the “in calibration” injector.

This value will change at every refilling of the odorant

calibration cylinder. See Screenshot 5.

Screenshot 5: Current Injector Data

If Specific Volume value related to the “in calibration”

injector is > than Entered Volume for Injector value,

then rotate the metering device screw on the injection

solenoid valve counterclockwise in order to reduce

orifice size.

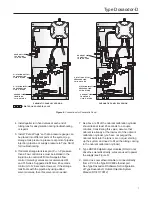

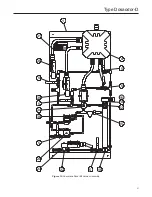

See Figures 12 and 13, item 39 for the injection

solenoid valve. See Figure 10, item 39G for Metering

Devices screw for injection solenoid valve.

If Specific Volume value related to the “in calibration”

injector is < than Entered Volume for Injector value

then do the opposite.

Use a common screwdriver for calibrating the

metering device.

Note

Turning the screw a little corresponds to

high odorant flow rate variation.

Wait at least two refilling cycles before adjusting the

metering device. Have at least two similar (+/- 5%)

value readings before validate it. See “% From Last”

value in Screenshot 5.

Specific Volume value is acceptable when it is equal to

entered value +/- 10%.

See “% From Start” value in Screenshot 5 (acceptable

values: 90% Entered Volume 110%).

Put the system in Disable mode.

Change Manual mode Gas Flow rate to the desired

value in working conditions.

Put the system in Auto mode to start injection.

Purge/Wash Cycle by Means of

Natural Gas (Odorant Recovery and

Gas Washing Cycles)

CAUTION

The purging/washing operation has

to be completed before any routine

or extraordinary maintenance

intervention and before dismantling the

Type Dosaodor-D odorizing system.

During washing operation with natural gas, the control

activates both injectors at the same time (to improve the

drying process and reduce time for the operation). Only

the selected injector is used in case of injector flush.

The Purge/Wash cycle drains out all the odorizing liquid

present in the injection system to allow partial or full

dismantling without particular problems (odor or toxicity)

for the operators.

The odorant inside the Type Dosaodor-D system is

pushed into the odorizer tank. Only a small part is

injected to the line.

Odorant Recovery Cycle must always take place

before Gas wash. Follow the procedure below (refer

to Type Dosaodor-D Software for Configuration of

Type Dosaodor-D Odorant Injection System

Manual (D103117X012)):

• Close the refilling manual valve close to the odorant

calibration cylinder (look at Figure 6).

• Put the system in Refill and Disabled mode

sequentially several times (refer to Type Dosaodor-D

Software for Configuration of Type Dosaodor-D

Odorant Injection System Manual (D103117X012)).

This will increase the odorant calibration cylinder

pressure (as the Gauge mounted on the odorant

calibration cylinder indicates).

• Put the system in Purge/Wash mode

Type Dosaodor-D Software for Configuration

of Type Dosaodor-D Odorant Injection System

Manual (D103117X012)).

• Open the refilling manual valve close to the odorant

calibration cylinder (look at Figure 6).

• Start Odorant Recovery Cycle (refer to Dosaodor-D

Software for Configuration of Dosaodor-D Odorant

Injection System Manual (D103117X012)).

18

Type Dosaodor-D