flow rate can also be configured manually to a fixed

value. Odorant injection rate is then calculated using

accumulated flow in order to reduce variability.

In cases where the station does not have a flow

computer, the Type ROC809 can be connected

directly to a pulse output from the turbine or an

analog output from a differential pressure transmitter

(Rosemount Types 3051 and 3095, etc.).

Variability between the calculated and actual injection

volume is used to automatically adjust injection

parameters for any changes in the system and

to detect alarm conditions or system failure, the

odorant calibration cylinder is used to monitor the

actual use of odorant. In the event of power failure,

configuration information and archived historical data

are maintained.

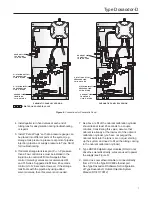

Type Dosaodor-D is designed to purge the odorant

back into the tank in the event that mechanical

maintenance is required. Odorant is pushed back

into the tank and gas is purged through the system to

absorb any remaining liquid.

General Safety Rules

Only qualified personnel shall install and operate the

odorizing system.

Odorizing systems should be installed, operated

and maintained in accordance with international and

applicable codes and regulations.

Installation, operation and maintenance procedures

performed by unqualified personnel may result in

unsafe operation.

This condition may result in equipment damage or

personal, environment injury. If a leak develops in

the system, the escaping gas may accumulate and

become a fire or explosion hazard. Immediately call

qualified service personnel in case of trouble.

The service engineers (operators and maintenance

workers of odorizing systems) shall comply, in any

case, with the following rules:

1. Always wear safety clothing to prevent the product

from coming in contact with the skin, eyes or to

prevent it from being inhaled;

2. In case of leaks or liquid spillage, be prepared to

neutralize or contain the liquid.

Site Requirements

Careful consideration when locating the ROC809 on

the site can help reduce future operational problems.

Consider the following items when choosing a location:

•

Local, state and federal codes often place

restrictions on locations and dictate site

requirements.

Examples of these restrictions are:

the amount of distance from a meter run, distance

from pipe flanges and hazardous area classifications.

Ensure that all code requirements are met.

• Choose a location for the ROC

that minimizes the

length of signal and power wiring.

•

The ROC809 is equipped for radio communications

should be located so the antenna has an

unobstructed signal path.

Antennas should not

be aimed into storage tanks, buildings or other tall

structures. If possible, antennas should be located

at the highest point on the site. Overhead clearance

should be sufficient to allow the antenna to be raised to

a height of at least 20 ft / 6 m.

• To minimize interference with radio communications,

choose a location for the ROC away from

electrical noise sources,

such as engines, large

electric motors and utility line transformers.

• Choose a location for the ROC

away from heavy

traffic areas to reduce the risk of being damaged

by vehicles.

However, provide adequate vehicle

access to aid monitoring and maintenance.

•

The site must comply with class limits of Part 15

of the FCC rules.

Operation is subject to the following

two conditions: (1) The device may not cause harmful

interference and (2) the device must accept any

interference received, including interference that may

cause undesired operation.

Compliance with Hazardous Area Standards

The ROC hazardous location approval is for Class I,

Division 2, Groups A, B, C and D. The Class, Division and

Group terms include:

1.

Class

defines the general nature of the hazardous

material in the surrounding atmosphere. Class I is for

locations where flammable gases or vapors may be

present in the air in quantities sufficient to produce

explosive or ignitable mixtures.

4

Type Dosaodor-D