Most frequent combinations.

A. 1 and 6 with 4 and/or 5

B. 2 and 3 with 6

C. 4 and/or 5 with 6

D. 2 and 3 should be used together

Pneumatic Panel Installation

Pneumatic Panel should be installed in the immediate

vicinity of the odorant pick-up point (absorption-type tank

or other type of tank).

All of the panel components are resistant to chemical

attack from all of the odorizing liquids, to the elements

and to those conditions specified in regulations

regarding safety and electrical equipment.

It is essential that the distance between the panel and

the injection location be as short as possible, as a

short route limits the quantity of odorant subjected to

pressure and thus reduces the chances of leakage of

liquid occurring.

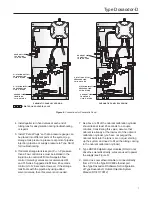

The pneumatic panel (Figure 3) is intended to be

wall mounted. Two spacing brackets are part of the

standard equipment supplied with the panel. The

standard equipment contains two brackets, standard or

extended injection wick, odorant filter and screws.

Four openings are provided for pipe connections and

they are located at the end points of the support panel.

The positions and sizes of the openings can be easily

identified from Figure 6.

Pneumatic Lines and Connections

The pneumatic connections between the

Type Dosaodor-D panel, the gas line and the odorant

tank should be carried out using stainless steel piping

only. Refer to Figure 6 for pipe sizes.

CAUTION

The pipeline connecting the

Type Dosaodor-D panel with the

odorant tank should be configured to

avoid the creation of possible air/gas

pockets (obstacles to the odorant flow).

Piping should be installed as straight as possible, with

a constant grade and without any sequences of upward

and downward inclines.

Polytetrafluoroethylene (PTFE) tape or thread sealer

should be used on all pipe fittings to prevent

odorant leakage.

Type ROC809 Controller Installation

Planning is essential to a good installation. Because

installation requirements depend on many factors,

such as the application, location, ground conditions,

climate and accessibility, this document only provides

generalized guidelines.

!

WARNING

Failure to follow the following installation

requirements could result in equipment

malfunction and loss of odorant

injection. Loss of odorant in the natural

gas supply could result in personal

injury and property damage from

undetected leaking natural gas.

Level Float and Switch Wiring

Type ROC809 must not receive the signals directly

from the odorant calibration cylinder (low and high

level). For safety reasons a barrier must be installed.

Barriecifications

Verify connection cable and field device capacitance

and inductance do not exceed the limits given for the

Intrinsically Safe barrier.

Level Switch Safe Parameters:

Ci (Equivalent input capacitance) = 20pF

Li (Equivalent input inductance) = 4μH

If the results are negative, condition 3 prevails on 2, since

cable resistance reduces circuit current (consequently

reducing the stored electrokinetic energy).

Cable parameters:

Cc (Equivalent input capacitance)

Lc (Equivalent input inductance)

Rc (Equivalent input resistance)

Environmental Requirements

NOTICE

The ROC809 requires protection

from direct exposure to rain, snow,

ice, blowing dust or debris and

corrosive atmospheres.

10

Type Dosaodor-D