Oxymitter 5000

8-22

Instruction Manual

IM-106-350, Rev 2.2

July 2008

HEATER NOT OPEN,

BUT UNABLE TO REACH

736°C SETPOINT

The temerature setpoint of 736°C can not be reached because the Oxymitter

5000 has an "autotune" function for establishing heater control parameters.

Probes mounted into processes that operate at above 600°C may have a

hard time controlling the temperature with the "autotune" function enabled.

To disable the autotune function, conduct the following procedure with the

LOI.

1. Select System.

2. Select Parameters.

3. Select Auto Tune?

4. Select No to disable the Auto Tune function.

CALIBRATION PASSES

BUT STILL READS

INCORRECTLY

There are a few fault conditions where no alarm indication is present and the

probe passes calibration but the O

2

reading may still be incorrect.

Probe passes calibration, but still appears to read high

There may be a leak that is permitting ambient air to mix with the process

gases. Since many combustion processes are slightly negative in pressure,

ambient air can be sucked into the cell area, biasing the O

2

reading upward.

1. Make sure that the calibration gas line is capped tightly between

calibrations. If autocal is used make sure the check valve is seating

properly.

2. If an abrasive shield is installed to protect the entire probe from

particulate erosion, a leak in the probe flange gasket can allow ambient

air to migrate down the annular space between the probe and shield,

and then into the cell. Always install a new probe flange gasket when

reinstalling a probe.

There may be a leak inside the probe itself, permitting the reference air

(20.95% O

2

) to mix with the process gases at the cell. To confirm this leak

condition instrument air will need to be connected for reference. Pressurize

the inside (reference side) of the probe by plugging the reference air exhaust

port with your finger for 1 minute. The O

2

reading should decrease slightly. If

the O

2

reading increases during this test there is a leak inside the probe.

1. Acid condensation inside the probe can degrade the red silicon tube

(32, Figure 9-3) that carries the cal gas to the cell. Remove housing (25)

to inspect this hose. (See Section 9: Maintenance and Service). Black

Viton™ material is optionally available with greater chemical resistance.

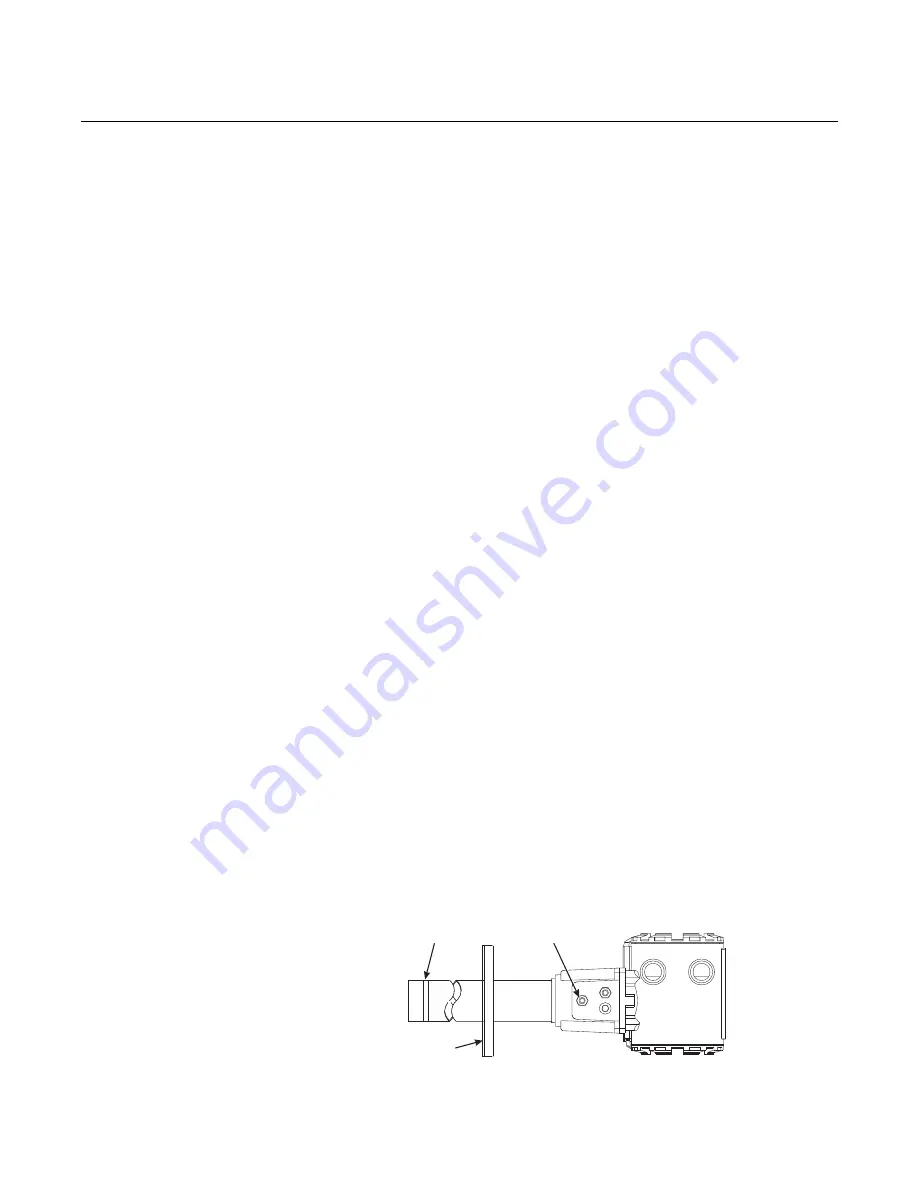

Figure 8-18. Probe Leakage

Paths

BOTTOM VIEW

38730098

PROBE HEAD

Corrugated

Seal

Reference Air

Exhaust Port

Probe

Flange

Gasket

Содержание Oxymitter 5000

Страница 2: ......

Страница 6: ......

Страница 12: ......

Страница 22: ...Oxymitter 5000 xii Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 42: ...Oxymitter 5000 1 20 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 62: ...Oxymitter 5000 2 20 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 74: ...Oxymitter 5000 4 6 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 78: ...Oxymitter 5000 5 4 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 94: ...Oxymitter 5000 7 6 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 140: ...Oxymitter 5000 9 22 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 184: ...Oxymitter 5000 B 2 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 204: ...Oxymitter 5000 D 14 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 222: ...Oxymitter 5000 E 18 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Страница 224: ...Instruction Manual IM 106 350 Rev 2 2 July 2008 Index 2 Oxymitter 5000 ...