36

C6.1.11/0718-0619/E

3.2 Refrigeration piping connections

3.2.1 Refrigeration piping installation and connections

WARNING

High pressure!

Risk of personal injury!

The units are pressurized with dry

air. Be careful when opening connections on a pressurized item.

IMPORTANT

Tubing quality! Installation contamination!

All interconnecting piping

should be of refrigeration grade, clean, dehydrated and must remain capped

at both ends until installation. Even during installation, if the system is left for

any reasonable period of time, eg, 2 hours, pipes should be re-capped to

prevent moisture and contaminant from entering the system.

Connection sizes! Unsuitable refrigerant flow rate!

Do not assume that the

service connection sizes on the unit (at the service valves) are in fact the

correct size to run the interconnecting refrigeration pipes. The service valve

sizes have been selected for convenience of installation and in some cases

these may be considered too small. However, for the very short pipe run within

the units these service connection sizes are adequate. All interconnecting

piping should be sized to satisfy the duty required.

IMPORTANT

Piping design pressure! Risk of CO

2

blow-off!

The CO

2

unit liquid and

suction line piping is designed for a design pressure (Ps) of 90 bar as

pressures around 85 bar can occur during normal operation. The installer must

always consider the system liquid and suction lines in terms of maximum

operating pressure. If the system piping design pressure is lower than 90 bar,

additional safety devices are required. The CO

2

unit can control different

receiver pressures depending on the application.

The pipes should be sized to ensure optimum performance and good oil return. The sizing must also

take into account the full capacity range through which a particular unit will need to operate.

The piping on the unit is made of K65, a high copper alloy tube designed for high operating pressures.

This kind of tube is more rigid than a standard copper tube; this must be considered for the design

and fixation of the piping system.

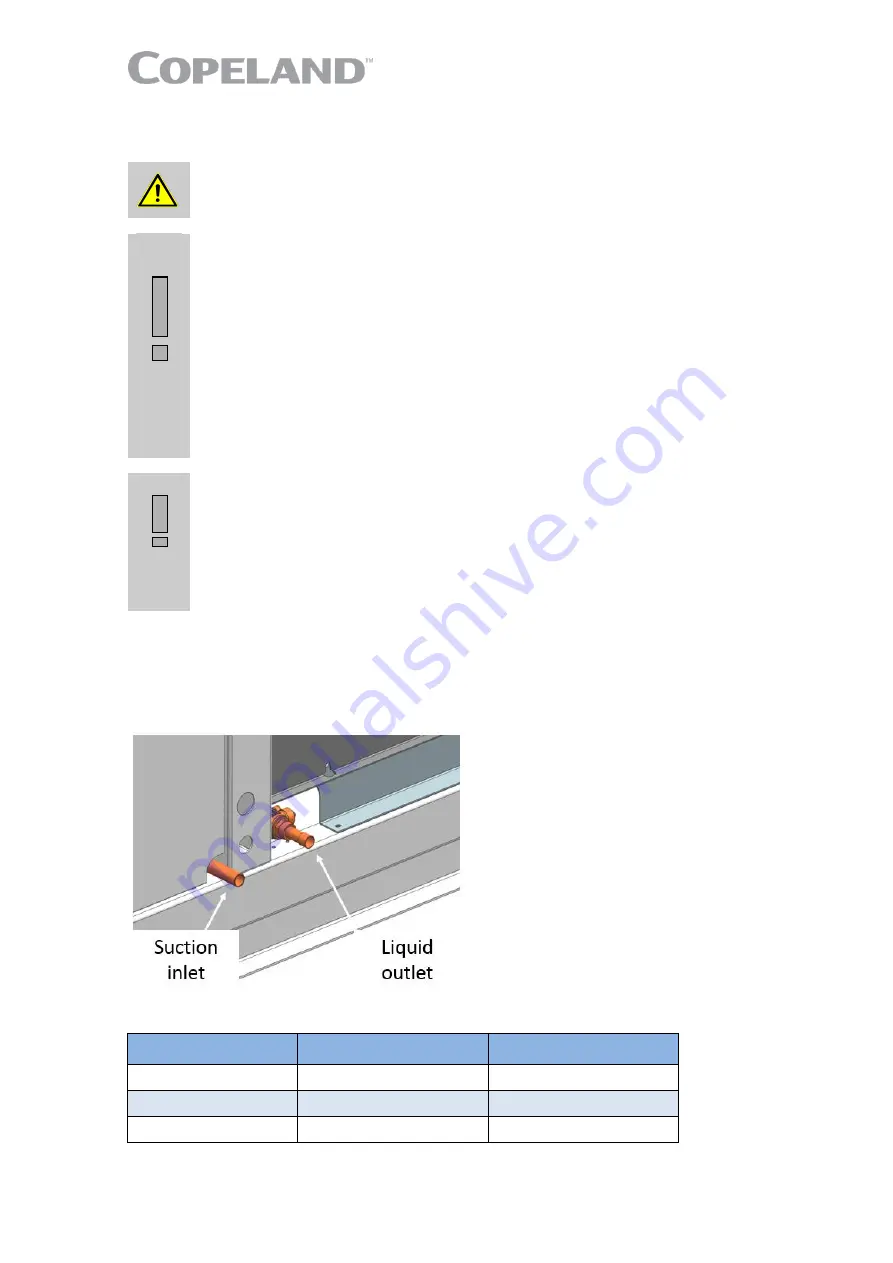

Figure 51: Piping connections

Unit

Suction line (ODS)

Liquid line (IDS)

OME-4MTL-05X

3/4" (19.05 mm)

5/8" (15.875 mm)

OME-4MTL-07X

3/4" (19.05 mm)

5/8" (15.875 mm)

OME-4MTL-09X

7/8" (22.23 mm)

5/8" (15.875 mm)

Table 20: Piping connections sizes

Содержание Copeland EazyCool OME-4MTL-09X

Страница 1: ...Copeland Eazycool CO2 Refrigeration Units Application Guidelines ...

Страница 5: ......

Страница 16: ...C6 1 11 0718 0619 E 11 2 7 8 Exploded view of the CO2 unit Figure 12 Exploded view of the unit ...

Страница 67: ...62 C6 1 11 0718 0619 E Appendix 4 Ecodesign overview tables according to Regulation 2015 1095 EU ...

Страница 68: ...C6 1 11 0718 0619 E 63 ...