12

C6.1.11/0718-0619/E

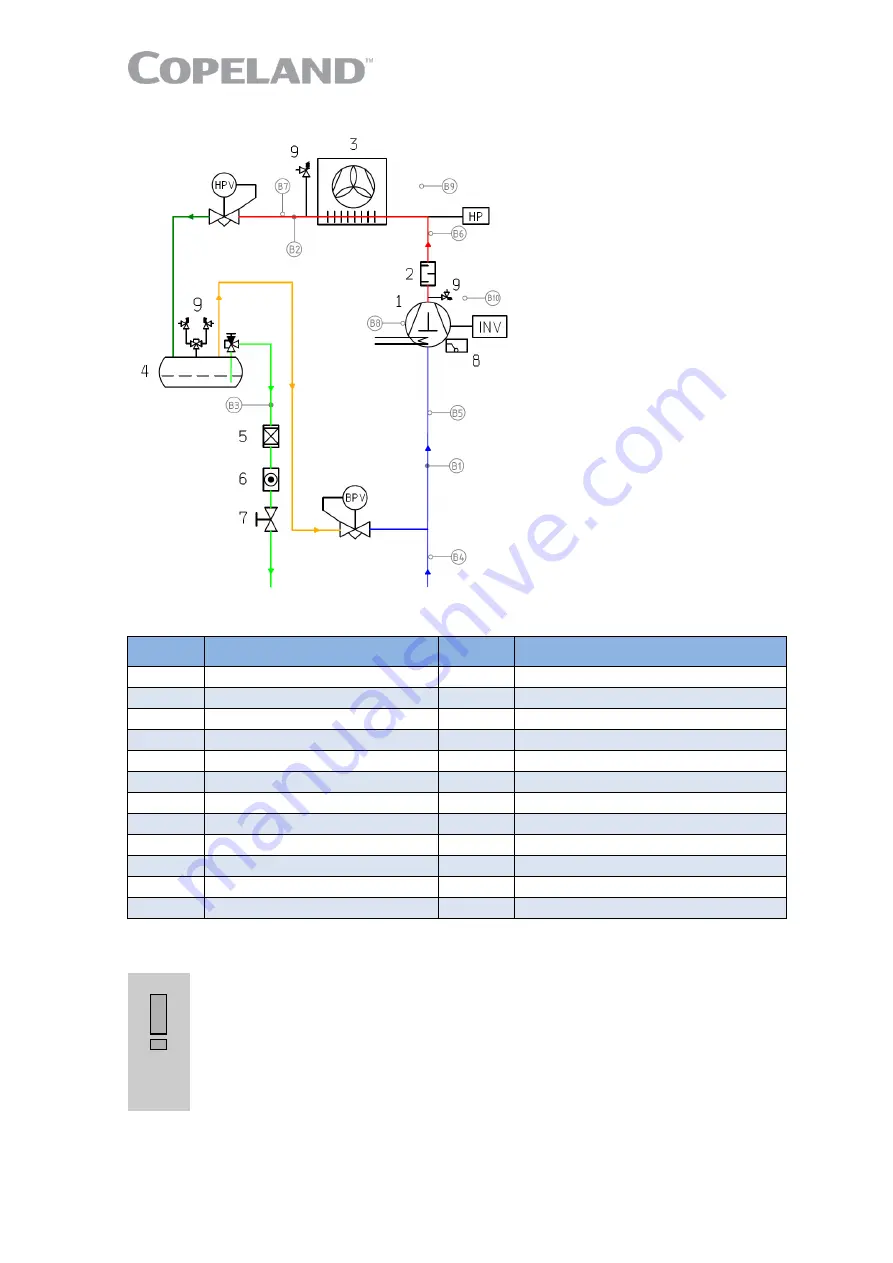

2.7.9 P&I diagram for CO

2

units

Figure 13: P&I diagram for CO

2

units

Position Description

Position Description

1

Copeland Stream compressor

INV

Compressor inverter

2

Discharge mufler

B1

Suction pressure

3

Gas cooler/condenser

B2

Discharge pressure

4

Flash tank

B3

Liquid receiver pressure

5

Filter-dryer

B4

Suction gas temperature unit

6

Sight glass

B5

Suction gas temperature compressor

7

Ball valve

B6

Discharge line temperature

8

OW5 oil watch

B7

Gas cooler temperature

9

Pressure relief valve

B8

Oil temperature

HPV

High pressure valve

B9

Ambient temperature

BPV

Bypass valve

B10

Cabinet temperature

HP

High pressure limiter

Table 6: Legend of the P&I diagram for CO

2

units

2.7.10 Design pressures

IMPORTANT

Piping design pressure! Risk of CO

2

blow-off!

The CO

2

unit liquid and

suction line piping is designed for a design pressure (Ps) of 90 bar as

pressures around 85 bar can occur during normal operation. The installer must

always consider the system liquid and suction lines in terms of maximum

operating pressure. If the system piping design pressure is lower than 90 bar,

additional safety devices are required. The CO

2

unit can control different

receiver pressures depending on the application (parameter

GC20

).

The unit has 2 different pressure areas:

▪

The design on suction side is made for a maximum allowable absolute pressure of 90 bar at

standstill. The section after the high-pressure valve (liquid line, liquid receiver, filter drier, sight

Содержание Copeland EazyCool OME-4MTL-09X

Страница 1: ...Copeland Eazycool CO2 Refrigeration Units Application Guidelines ...

Страница 5: ......

Страница 16: ...C6 1 11 0718 0619 E 11 2 7 8 Exploded view of the CO2 unit Figure 12 Exploded view of the unit ...

Страница 67: ...62 C6 1 11 0718 0619 E Appendix 4 Ecodesign overview tables according to Regulation 2015 1095 EU ...

Страница 68: ...C6 1 11 0718 0619 E 63 ...