Manual: R1300-X-00-X_EN Release: 1.04 © Elotech GmbH Page 3/20

III.

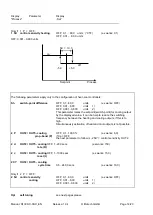

Connection Diagram

L / -

1

29

+

15

+ OUT 2:

bistable, 0/18 VDC

OUT 4,

Continuous

N / +

2

30

-

16

Com. GND

3

31

+

17

+ OUT 1:

bistable, 0/18 VDC

OUT 5,

Continuous

4

32

-

18

OUT 1

5

33

B

RxD in

19

Relay

RS485

RS232

6

34

A

TxD out

20

7

35

TxD in

21

8

36

RxD out

22

GND, Analogue Setpoint Input

OUT 2

9

37

GND

23

+

0/4...20 mA, Analogue Setpoint Input

Relay

10

24

+

0...10 VDC, Analogue Setpoint Input

11

25

+

12

26

+

+

OUT 3

13

27

-

-

Relay

14

28

Z1

It is not permitted to connect the grounds of the sensor-, bist. voltage- and continuous-outputs with each

other.

RTD 2-wire connection:

jumper between terminals 27 and 26.

OUT1: Control output

2-point-controller:

"Heating" e.g „Cooling“

3-point-controller:

„Heating“

3-point-step-controller:

„On“

OUT2: Control output

2-point-controller:

Alarm 2

or alarm output

3-point-controller:

„Cooling“

3-point-step-controller:

„Off“

OUT3: Alarm Output

Alarm 3

OUT4: Continuous Output

R1300-2:

Controller Output

R1300-3:

Function: See Configuration Level. Controller output or

analogue process value output or analogue setpoint output

OUT5: Continuous Output

R1300-3:

Function: See Configuration Level. Controller output or

analogue process value output or analogue setpoint output

Setpoint Controlling:

K1: open = Setpoint 1 (SP1) valid

K1: closed = Depends of the configuration (see Parameter Co.SP):

Setpoint 2 (SP2) or external, analog Setpoint value (SPA) valid

Adjustment lock

(LOC)

:

K2: open = Adjustment lock only via "Software Code"

K2: closed. = Adjustment locked (according to the chosen Software Code)

R Load

R Load

K1

K2

Pt 100 / RTD

TC

0...10 VDC

0/4...20mA