28

K.6

Introduction

WARNING

Dismantling operations must be

carried

out

by

specialised

personnel.

WARNING

Work on the electrical equipment

must only be carried out by

specialised personnel, with the

power supply disconnected.

K.7

Waste storage

At the end of the product's life-cycle, make sure it is not

dispersed in the environment.

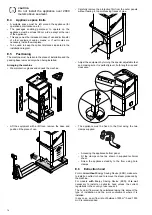

Depending on the model, the doors must be removed before

scrapping the appliance.

SPECIAL waste materials can be stored temporarily while

awaiting treatment for disposal and/or permanent storage. In

any case, the current environmental protection laws in the

user's country must be observed.

K.8

Procedure regarding appliance

dismantling macro operations

Before disposing of the machine, make sure to carefully check

its physical condition, and in particular any parts of the

structure that can give or break during scrapping.

The machine's parts must be disposed of in a differentiated

way, according to their different characteristics (e. g. metals,

oils, greases, plastic, rubber, etc.).

Different regulations are in force in the various countries,

therefore comply with the provisions of the laws and compe-

tent bodies in the country where scrapping takes place. In

general, the appliance must be taken to a specialised

collection/ scrapping centre.

The symbol on the product indicates that this

product should not be treated as domestic

waste, but must be correctly disposed of in

order to prevent any negative consequences

for the environment and human health. For

further information on the recycling of this

product, contact the local dealer or agent, the

Customer Care service or the local body

responsible for waste disposal.

WARNING

Make the appliance unusable by

removing the power cable and

any compartment closing devi-

ces, to prevent the possibility of

someone

becoming

trapped

inside.

NOTE!

When scrapping the machine, the “CE“ marking,

this manual and other documents concerning the

appliance must be destroyed.

L

TROUBLESHOOTING

L.1

Common faults

DISHWASHER DOES NOT WASH

WELL

1. Check if the suction filter is dirty and clean it thoroughly.

2. Check if the wash jets are clogged by solid food remains.

3. Check that the initial amount of detergent or subsequent additions are correct.

4. The selected wash cycle is too short. Repeat the cycle.

5. Check the tank temperature.

6. Check that the dishes are stacked correctly in the racks.

GLASSES AND DISHES ARE NOT

DRIED PROPERLY

1. Check the instructions for the amount of rinse-aid (see H.2

paragraph).

2. Check that there is rinse-aid in the container and if necessary top up.

3. Check the set amount of rinse-aid (see H.2

paragraph).

4. Check the water temperature of the boiler.

CONDENSATION ON GLASSES

1. Check that there is rinse-aid in the container and if necessary top up.

2. Check the set amount of rinse-aid (see H.2

paragraph).

3. Remove the rack of glasses immediately the cycle has ended.

STAINS ON THE GLASSES

1. Only use “non-foaming” products for professional dishwashers.

EXCESSIVE FOAM IN THE TANK

1. Check that the wash water temperature is not less than 50

℃

.

2. Check if the amount of product dispensed by the detergent dispenser is excessive

(see H.2

paragraph).

3. Ensure that the tank has not been cleaned with unsuitable cleaners. Drain the

tank and rinse thoroughly before new wash cycles.

4. If a foaming detergent has been used, drain and refill the tank with water until the

foam disappears.

SMEARS OR SPOTS ON THE

GLASSES

1. Reduce the amount of rinse-aid (see H.2

paragraph)

THE WASH OR RINSE ARMS TURN

SLOWLY

1. Remove and thoroughly clean the arms.

2. Clean the wash pump suction filter.

Содержание EHTA060

Страница 2: ...2 Installation diagram Manual hood type ...

Страница 3: ...3 Installation diagram Automatic hood type ...

Страница 30: ......

Страница 31: ......

Страница 32: ...Electrolux Professional SPA Viale Treviso 15 33170 Pordenone www electroluxprofessional com ...