16

Power supply 380-415V 3N

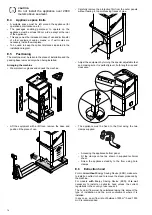

Open the power supply terminal board and insert the jumpers

provided as follows: one jumper between terminals 2 and 4

and another between terminals 4 and 6. Using a suitable

power supply cable (see C.1

Main technical characteristics

table), connect the three phases to terminals 1, 3 and 5, the

neutral to terminal 6 and the earth wire to the terminal

.

Power supply 220 - 230V 3

Open the power supply terminal board and insert the jumpers

provided as follows: one jumper between terminals 1 and 2,

one between terminals 3 and 4 and another between terminals

5 and 6. Using a suitable power supply cable (see C.1

table) connect the three phases to

terminals 1, 3 and 5 and the earth wire to the terminal

.

Power supply 220 - 230V 1N

Open the power supply terminal board and insert the jumpers

provided as follows: two jumpers between terminals 1, 3, 5 and

another two between terminals 2, 4 and 6. Using a suitable

power supply cable (see C.1

Main technical characteristics

table), connect the phase and neutral to terminals 5 and 6

respectively and the earth wire to the terminal

.

E.10.1 Connections provided for energy control

This appliance is designed for an external energy consumption

control.

Connect the energy peak controller across terminals 11 and 12.

CAUTION

A normally open (n. o.) contact of the

controller must be connected across ter-

minals 11 and 12. When this contact

closes the boiler heating elements are

disconnected. Using the dishwasher in

these conditions may increase the cycle

time.

E.11

Safety devices

• An automatic-reset overload protector incorporated in the

electric pump windings cuts off the power to the pump in

case of faulty operation.

• A device prevents the booster water from returning back

into the system in the event of a water supply system fault.

• An overflow pipe connected to the discharge ensures a

constant water level in the tank.

• If the water level in the tank is too high, the drain pump (if

present) automatically activates to empty out the excess

water.

IMPORTANT

The Manufacturer declines any liability if the

accident-prevention regulations are not respected.

E.12

“HACCP“ arrangement

In some models the machine is not arranged for the “HACCP“

connection. The “HACCP“ kit can be ordered as an accessory.

When the machine is arranged for the “HACCP“ connection it

is still necessary to order the network connection cable.

Connect the “HACCP“ network to terminals 2 and 3 of

connector X4.

L1

L2

L3

L1

L2

L3

11

12

Содержание EHTA060

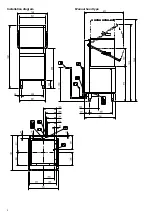

Страница 2: ...2 Installation diagram Manual hood type ...

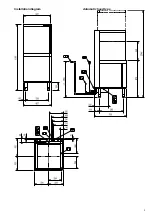

Страница 3: ...3 Installation diagram Automatic hood type ...

Страница 30: ......

Страница 31: ......

Страница 32: ...Electrolux Professional SPA Viale Treviso 15 33170 Pordenone www electroluxprofessional com ...