15

E.7

Disposal of packing

The packing must be disposed of in compliance with the

current regulations in the country where the appliance is used.

All the packing materials are environmentally friendly.

They can be safely kept, recycled or burned in an appropriate

waste incineration plant. Recyclable plastic parts are marked

as follows:

Polyethylene

• Outer wrapping

• Instructions bag

Polypropylene

• Straps

Polystyrene foam

• Corner protectors

The parts in wood and cardboard can be disposed of,

respecting the current regulations in the country where the

machine is used.

E.8

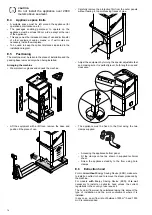

Plumbing connections

• Connect the appliance water supply pipe “WI“ (see the

) to the mains, fitting a cut-off tap, the

filter provided and a pressure gauge between the appliance

and the mains (see figure below).

• Check that the dynamic water supply pressure, measured

between the appliance and the main, is between between

50 and 700 kPa [0.5 - 7 bar] (test while dishwasher tank or

boiler is filling with water).

NOTE!

If the pressure is too high, fit a suitable pressure

reducer on the inlet pipe.

• On the model with free-fall drainage:

connect the waste outlet pipe (detail “D“ in the

) to the main drain pipe, fitting a trap, or place the

outlet pipe over an “S“ trap set into the floor.

• On the model with drain pump:

position the outlet pipe at a height anywhere between 750

and 1000 mm from the floor. Check that about 3 litres of

water flow out of the outlet pipe during the rinse cycle.

CAUTION

Always use a new set of joints if you

remove and reinstall the water inlet pipe to

the appliance.

IMPORTANT

Watermark labelled appliances must be installed in

accordance with AS/NZS 3500.1 and drainage to

be in accordance with 3500.2. On models with ESD,

an approved dual check valve must be installed

upstream.

E.9

Plumbing circuits

Hood dishwasher with drain pump

LEGEND

•

WI =

Water inlet

•

D =

Drain

•

M1 =

Wash pump

•

M3 =

Rinse pump

•

M4 =

Drain pump

•

AG =

Air Gap

•

YV1 =

Filling solenoid valve

E.10

Electrical connections

WARNING

Work on the electrical systems

must only be carried out by a

specialised personnel.

• Connection to the power supply must be carried out in

compliance with the regulations and provisions in force in

the country of use.

• Make sure the machine power supply voltage specified on

the rating plate matches the mains voltage.

• Make sure the system power supply is arranged and able to

take the actual current load and that it is executed in a

workmanlike manner according to the regulations in force in

the country of use.

• The earth wire from the terminal board side must be longer

(max 20 mm) than the phase wires.

• Connect the power cable earth wire to an efficient earth.

The equipment must also be included in an equipotential

system, whose connection is made by means of screw EQ

(see par.

) indicated by the symbol

.

The equipotential wire must have a section of at least 10

mm

2

.

!

Содержание EHTA060

Страница 2: ...2 Installation diagram Manual hood type ...

Страница 3: ...3 Installation diagram Automatic hood type ...

Страница 30: ......

Страница 31: ......

Страница 32: ...Electrolux Professional SPA Viale Treviso 15 33170 Pordenone www electroluxprofessional com ...