E D R O

D

y n a

W

a s h

®

T

h r e e

P

o c k e T

W

a s h e r

- e

x T r a c T o r s

21

Hold Down Bolts: Should be rechecked and tightened after running the first four (4) loads.

Bushings, bearing bolts and bearing plate bolts should be checked per Section 6.

Air Pressure Safety Switch: De-energizes the machine when air pressure drops below 50 PSI

(2.5 bar). To adjust the air pressure switch, turn the knurled adjustment screw clockwise (in) to

raise setting and counter-clockwise to reduce setting.

Vibration Switch or Sensor: Is preset to stop the machine when it becomes out of balance.

Rigid mount models (DW & DW_PT) have a factory preset sensor located in the electrical panel.

Adjust for sensitivity by tilting angle of sensor.

Soft mount models (DW_SM & DW_PTSM) have a sensor located between the frame and

floating tub. Adjust sensitivity by placing activating rod in microswitch.

Complete Warranty Registration Card and Return to EDRO: This is located in the document

package shipped in the machine’s electrical panel box.

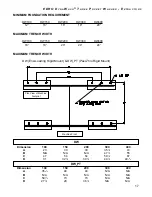

Plumbing

1. The hot water inlet feeds the automatic supply injection system, (optional).

2. EDRO supplies a valve for direct steam (optional); however, all DynaWash

®

machines are equipped with a built-in muffler so steam can be injected manually or

an automatically controlled valve can be added anytime in the future.

3. All DynaWash

®

machines are equipped with an air filter, oiler, and pressure regulator.

DynaWash

®

machines require 80 to 100 PSI, and consume, on the average, 3.5 cu.

ft./hr. The air connection to the machine is ¼” NPT. Install a shut-off valve on air line.

4. All DynaWash

®

machines are equipped with DynOzone. No external connections to

the machine are required for this feature.

5. Gate and globe valves as well as incoming hose lines are not supplied with the unit.

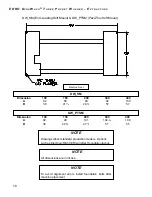

Electrical

Run the electrical cable to the washer’s electrical panel and attach the wires to the terminal strip

marked L1, L2, and L3.

SERVICE CONNECTIONS

NOTE

If cylinder does not spin clockwise (as viewed from front

of machine) in forward wash mode or in extract, remove

power, check phase connection or swap any two incoming

wires to main power terminal or verify inverter settings.