E D R O

D

y n a

W

a s h

®

T

h r e e

P

o c k e T

W

a s h e r

- e

x T r a c T o r s

19

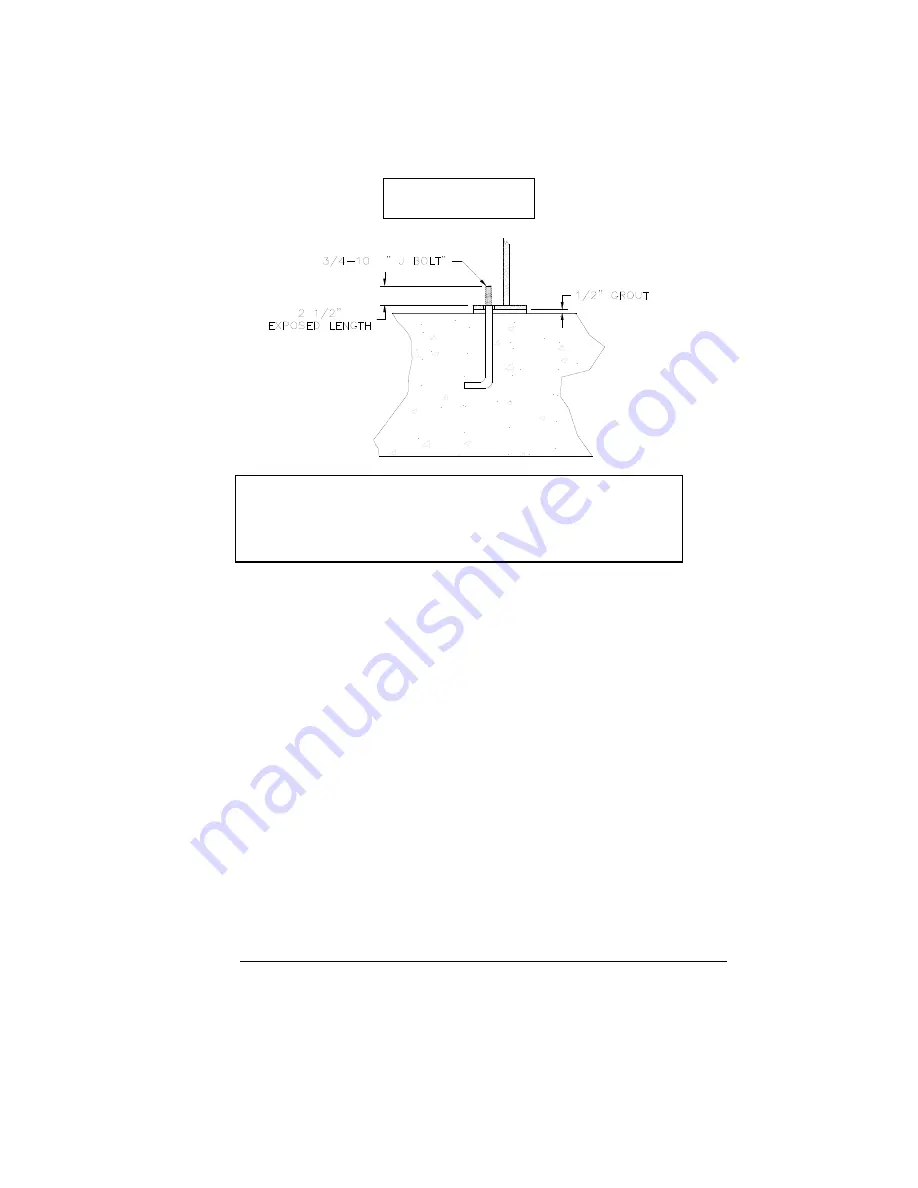

It is very important to understand that proper grouting of DynaWash

®

machines will result in

best performance. Correct grouting will assure perfect alignment of the machine with the floor.

GROUTING

View of Bolting and

Grouting Requirement

RIGID MOUNT MODELS (DW & DW_PT):

First, make the foundation level and flat. Next, pour grout in area that the base of the machine

will be located. Then lower the machine on the grouted area evenly. Check level front to back

and side to side. Pull down high side(s) using foundation bolts. Allow grout to harden. Install

all flat washers and lock washers and tighten all nuts. After service connections are made run a

cycle and recheck that all nuts are tight. Make periodically checks as follows:

1.

Daily for one (1) week.

2.

Weekly for one (1) month.

3.

Set up periodic inspection. (Section 6).

DYNA

MOUNT SOFT MOUNT MODELS (DW_SM & DW_PTSM):

Install Soft Mount models as in paragraph above. Before loading and running the first cycle

adjust the suspension system to the following measurements. Bottom of front plate to base

must be 1

1

⁄

4

” and front plate must be level side to side. Bottom of rear plate to base must be 1

1

⁄

8

” and rear plate must be level side to side. When machine is fully loaded with water it should

be level front to back.

STANDARD PLUMBING CONNECTIONS

PNEUMATIC CONNECTIONS

All DynaWash

®

machines require a single compressed air source of three-quarter (

1

⁄

4

”) NPT at a

minimum of 80 PSI (5.4 bar).

DW100

DW150

DW200

DW300

DW400

Inlet Valve

1

1

⁄

4

”

2”

2”

2”

2”

Drain Valve 4”

6”

6”

8”

8”

NOTE

Reference installation drawings for proper length of J-bolt

and concrete depth per model.