To order parts and supplies: 800.343.9353 >> eastwood.com

9

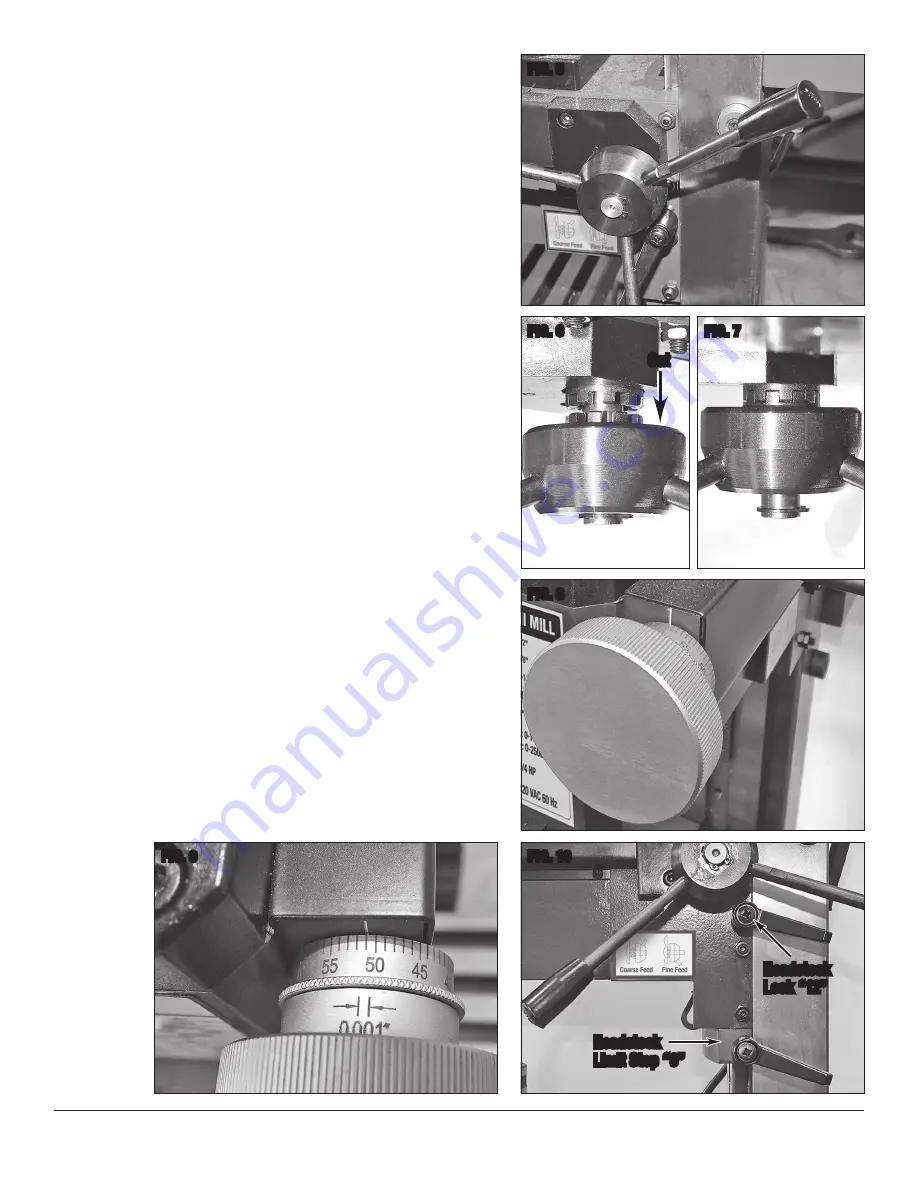

• The Headstock vertical travel is controlled by the Downfeed Handwheel

“10”

(FIG 5)

which drives a pinion gear along a Column mounted toothed rack.

It has both “Coarse” and “Fine” adjustments as described below:

- The “Coarse” adjustment provides a faster downward motion when

using as a drill press or as a rough positioning adjustment for precision

cutting operations. For “Coarse” adjustment, pull the Downfeed

Handwheel out to disengage the Castellated Drive Collar, allowing it to

turn

(FIG 6)

.

NOTE:

The Gauge and Pointer for the “Coarse” adjustment are

located at the left side of the Column.

- To lock in the “Fine” adjustment, push the Downfeed Handwheel in to

engage the Castellated Drive Collar

(FIG 7)

.

• The vertical Headstock travel is then finely adjusted by the Fine Downfeed Hand-

wheel

“11”

which provides a “fine tuning” precise positioning of the Headstock

along the Column

(FIG 8)

.

• Rotate the Fine Downfeed Handwheel Clockwise to lower the Headstock and

Counterclockwise to raise it. The Fine Headstock Handwheel moves the Head-

stock vertically 0.060” per revolution in fine increments of 0.001” as indicated

on the Pointer and Radial Gauge

(FIG 9)

built into the base of the Fine Downfeed

Handwheel

“11”

. Note that the Radial Gauge can be rotated to allow for indexing.

NOTE:

Refer to “Backlash Compensation” section of this Manual.

• The Headstock Limit Stop

“9”

limits the downward travel of the Headstock which

serves to limit depth of travel cut

(FIG 10)

.

• The Headstock Lock

“12”

locks the vertical position of the Headstock on the

Column

(FIG 10)

.

FIG. 8

FIG. 9

FIG. 10

Headstock

Lock “12”

Headstock

Limit Stop “9”

✓

✓

FIG. 5

✓

Out

FIG. 7

FIG. 6