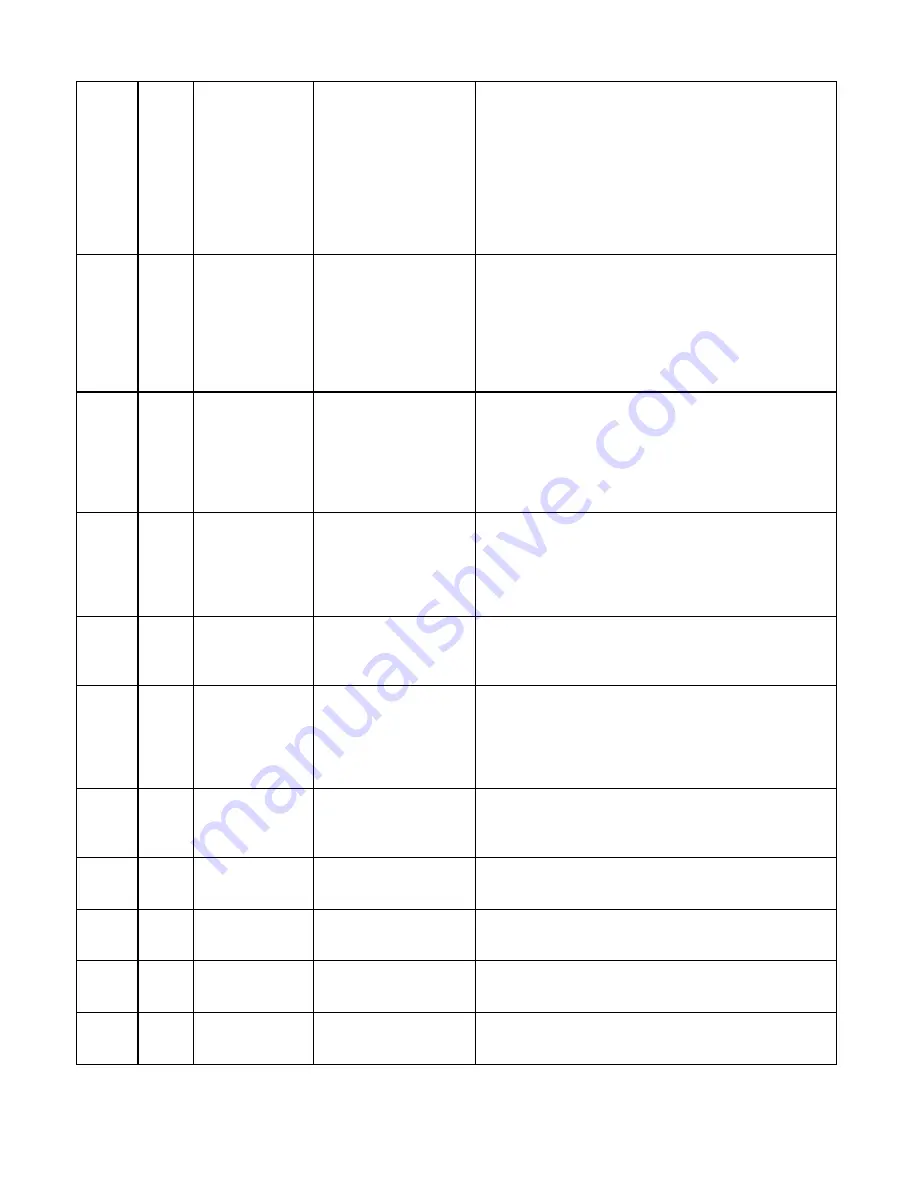

7382

29570

Resolver output level

too low

Reaction 5: Switch-off of the

current immediately (without

ramp), application of the

brake

Malfunction (motion caused by external source) of the motor

during automatic commutation, starting current too great, incorrect

parameter for commutation direction (use MotorManager to

determine the values). Check feedback resolution (per pitch) and/or

number of feedback or motor poles. A motor phase has been

(temporarily) interrupted.

Post-pulse oscillation of the drive due to a too high excitation in a

feebly attenuated system ->= increase O2190.1

AutoCommuntationControl_Ramptime and/or vary O2190.4

AutoCommutationControl MotionReduction.

7383

29571

Synchronization of

resolver excitation

Reaction 5: Switch-off of the

current immediately (without

ramp), application of the

brake

Eliminate external influence on the motor or device current is too

small resp. friction is too high.

Post-pulse oscillation of the drive due to a too high excitation in a

feebly attenuated system ->= increase O2190.1

AutoCommuntationControl_Ramptime and/or vary O2190.4

AutoCommutationControl_MotionReduction.

The commutation direction may be badly parameterized (use

MotorManager to determine the values).

7385

29573

Position difference

between load

mounted and motor

feedback too high

Reaction 2: Downramp /

apply brake / de-energize..

Avoid external influences on the motor, check feedback (sufficient

EMC immunity/shielding, resolution not configured). In very easy

running systems, it may be necessary to increase O2190.1

AutoCommutationControl_Ramptime. If needs be, increase O2190.7

AutoCommutationControl_Standstillthreshold as well.

7390

29584

SinCos internal

feedback error (group

bit)

Reaction 2: Downramp /

apply brake / de-energize..

Increase starting current O2190.2 and eliminate very high direction

dependence or friction if any. Check feedback resolution and/or

number of feedback or motor poles. With a high inertia (or

mass)/torque constant KT ratio, it might in addition be necessary to

reduce the motion threshold O2190.3.

7391

29585

Feedback level

exceeds limit

Reaction 5: Switch-off of the

current immediately (without

ramp), application of the

brake

Increase the starting current or eliminate external influence on the

motor. Check feedback resolution and/or number of feedback or

motor poles, update firmware to a release higher than 04_2005-3

(Firmware V02.07.16).

7392

29586

Feedback level too

low

Reaction 5: Switch-off of the

current immediately (without

ramp), application of the

brake

Increase automatic commutation starting current, eliminate motor

block, check parameters for motor current (too small, device

extremely under-dimensioned), current controller unstable. With a

high inertia (or mass)/torque constant KT ratio, it might in addition

be necessary to reduce the motion threshold O2190.3.

7393

29587

SinCos RS-485

communication error

(multiple bit)

Reaction 2: Downramp /

apply brake / de-energize..

Connect motor resp. check wiring. In the case of high winding

resistance reduce peak current so that Rkk*Imax is inferior to

Umains*0.8.

The power stage may be defective.

7394

29588

Feedback EEPROM

data invalid

Reaction 2: Downramp /

apply brake / de-energize..

Check and correct feedback sensor adjustment as well as feedback

wiring.

7395

29589

Error while storing

data in feedback

EEPROM

Reaction 2: Downramp /

apply brake / de-energize..

Increase baud rate

7396

29590

Checksum error

SinCos® EEPROM

Reaction 2: Downramp /

apply brake / de-energize..

Check feedback and feedback cable.

7397

29591

SinCos® FF feedback

type is not supported

Reaction 2: Downramp /

apply brake / de-energize..

Check feedback and feedback cable or reduce lower limit value

(Obj287.10) if needs be