12

E-flite Extra 300 32e ARF Assembly Manual

Landing Gear and Wheel Installation

Required Parts

Fuselage assembly Axle with hardware (2)

#4 washer (5)

Aluminum landing gear

Main wheel (2)

Wheel pant (left and right)

4-40 x 1-inch socket head screw (3)

4-40 x 3/8-inch socket head screw (2)

Required Tools and Adhesives

Hex wrench or ball driver: 1.5mm, 3/32-inch

Threadlock

Nut driver: 7mm

Flat file

Pliers or adjustable wrench

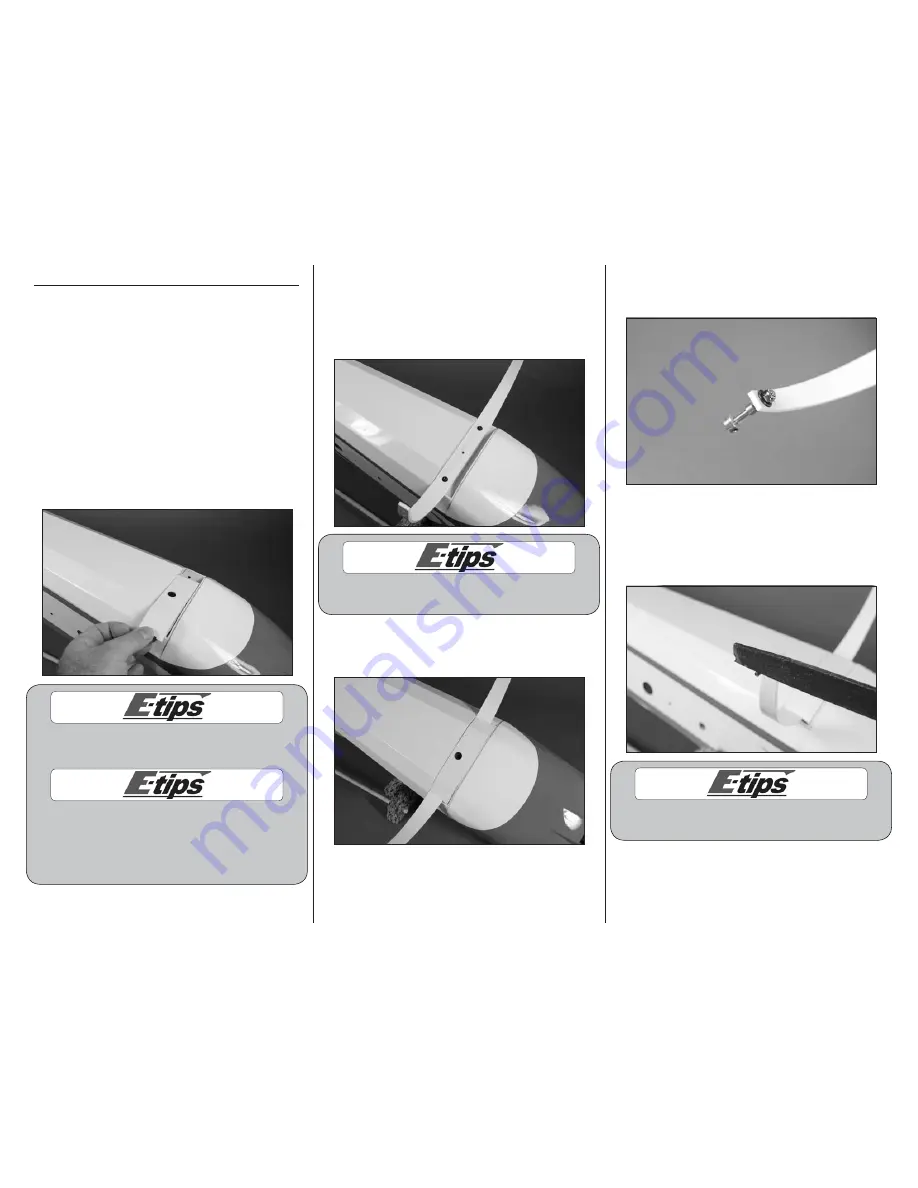

1. Remove the landing gear fairing from the

fuselage and set it aside.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

The landing gear can only be installed in one

direction. If the holes in the landing gear don’t

align with the blind nuts in the fuselage, rotate

the gear front-to-back so the holes are aligned

with the blind nuts installed in the fuselage.

2. Attach the landing gear using two (2) 4-40 x

1-inch socket head screws and two (2) #4 washers.

Use a 3/32-inch hex wrench or ball driver to

tighten the screws. Only install the outer screws

as shown in the photo. The center hole is for the

attachment of the landing gear fairing.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

3. Use a 4-40 x 1-inch socket head screw and

#4 washer to attach the landing gear fairing to

the fuselage.

4. Attach the axle to the landing gear. Use a 7mm

nut driver to tighten the locknut while holding the

axle with an adjustable wrench or pliers.

5. Use a 1.5mm hex wrench to loosen the setscrew

in the wheel collar to remove the collar. Use a file

to make a flat area for the first 1/4-inch (6mm) on

the bottom of the axle. This will provide an area to

tighten the setscrew, making it more secure.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.