18

E-flite Extra 300 32e ARF Assembly Manual

Elevator Installation

Required Parts

Fuselage assembly Control horn assembly

Nylon control horn Elevator joiner wire

CA hinge (6)

Clevis

Clevis retainer

Elevator (left and right)

Pushrod wire, 3

1

/

2

-inch (90mm)

Plastic packaging from model

Required Tools and Adhesives

Scissors

Medium grit sandpaper

Low-tack tape

Thin CA

30-minute epoxy

Toothpick

T-pins

Hobby knife with #11 blade

Pin vise

Drill bit: 1/16-inch (1.5mm)

Threadlock

Phillips screwdriver: #2

Pliers

Mixing cups

Paper towels

Rubbing alcohol

Mixing sticks

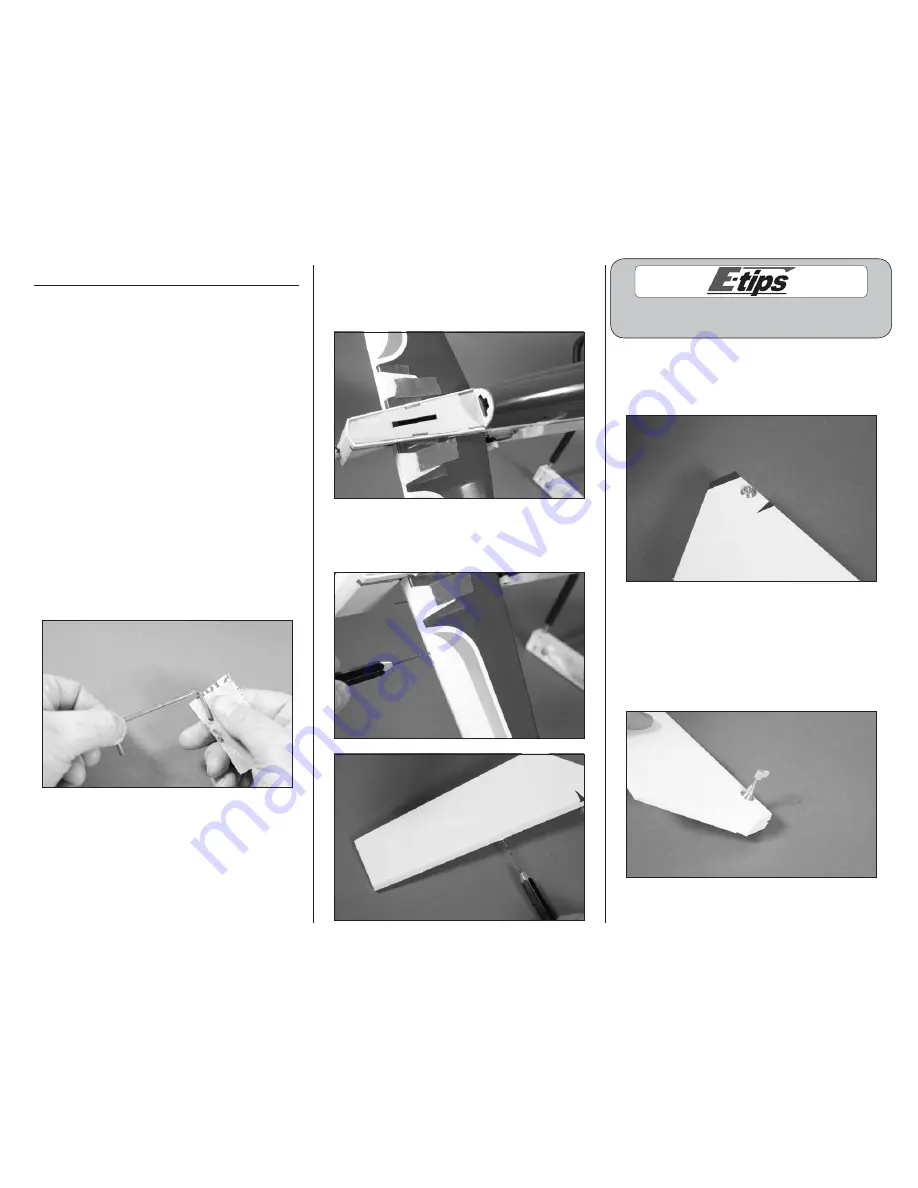

1. Use medium grit sandpaper to lightly sand the

ends of the elevator joiner wire. This will provide a

surface for the epoxy to adhere to.

2. Cut two strips of the clear plastic film the model

was packaged in using scissors. Use low-tack tape

to tape the plastic to the elevators so the joiner wire

isn’t accidentally glued to the stabilizers.

3. Use a pin vise with a 1/16-inch (1.5mm) drill

bit to drill a hole in the center of each of the hinge

slots in both the elevators and stabilizers.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

4. Remove the tapered nut and one countersink

from the control horn screw. Slide the screw and

remaining countersink into the hole in the elevator.

The screw must exit to the bottom of the elevator.

5. Slide the countersink back onto the control horn

screw. The tapered nut is then threaded on the

screw to secure its position on the elevator. Use

a #2 Phillips screwdriver and pliers to tighten the

hardware. Thread the nylon control horn onto the

control horn screw so it is flush with the end of the

screw as shown.