Drivecon Inc. reserves the right to alter or amend the above information without notice.

6 HOW TO ACCESS THE HOIST CONDITION MONITORING UNIT

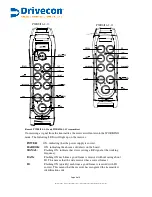

THROUGH PWRSII 6-2-13 RADIO SERVICE MODE

(IFAPPLICABLE

).

6.1 General Description of Service Mode

For PWRSII 6-2-13 systems, there is a special “Service Mode” of operation for

maintenance and set up of the Hoist Condition Monitoring Unit via radio.

This unit is connected to the receiver PWRS 6-2-13 by a serial data communication

CL20mA.

When in Service mode, the transmitter PWRS 6-2-13 is able to act as a data console for

the Hoist Condition Monitoring Unit, sending commands and receiving information,

using the radio link and the appropriate software in the transmitter PWRS 6-2-13 and in

the receiver PWRS 6-2-13.

During the Service Mode of operation, due to the amount of data being sent in the

reverse link, the amount of frames per second in reverse mode is increased such that the

feedback in the display is fast enough. The movements of the crane in this mode of

operation are inhibited, this is, there are no movement orders being sent by the

transmitter or acknowledged by the receiver. The Stop relays are activated.

PLEASE NOTE:

It could be too slow to enter in service mode by the receiver if the transmitter and the

receiver are in different channels. Whenever possible, avoid the scanning of radio

channels.

6.2

Entering the Service mode.

To access the Hoist Condition Monitoring Unit mode follow

the sequence:

1. Install a charged battery in the transmitter.

2. Move close to the receiver.

3. Turn on the key-switch.

4. Push down STOP pushbutton (If it was in up position.

5. Pull up STOP push button.

6. Press Pushbutton UP in second step, and then START.

The system enters in Service Mode. See figure 9.

Figure 9 Entering the Service mode.

Page 13 of18