Maintenance

A36951-C.doc

167/236

2

1

3

4

5

6

7

8

10

12

11

13

9

14

15

17

16

18

19

20

21

22

23

24

25

26

27

28

29

31

30

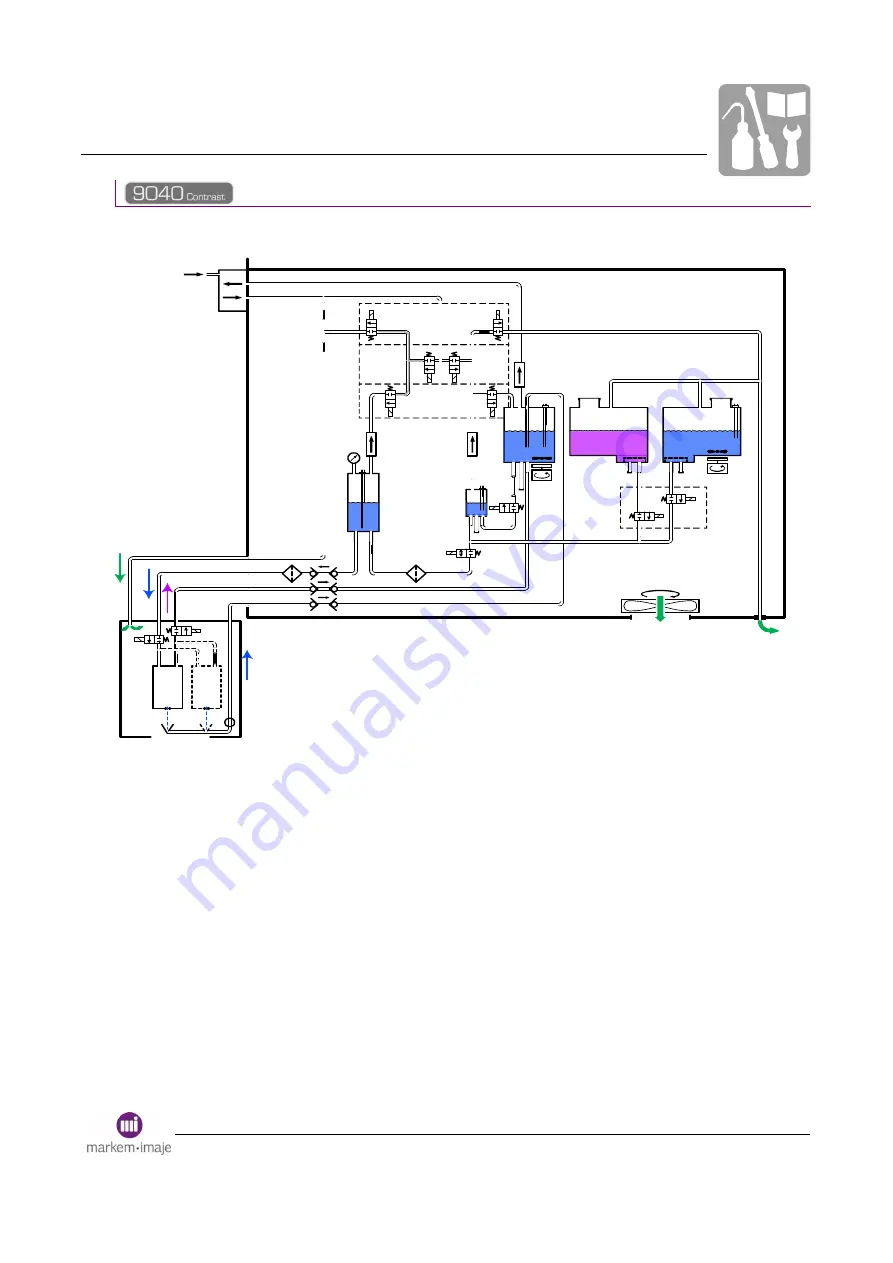

1

Air supply

2

Discharge electrovalve

3

Atmospheric pressure

electrovalve

4

Charge electrovalve

5

Air transfer electrovalve

6

Equi-air electrovalve

7

Equi-visc electrovalve

8

Coalescence filter

9

Recovery tank

10

Additive tank

11

Ink tank

12

Pressure sensor

13

Coalescence filter

14

Coalescence filter

15

Stirrer motor

16

Additive addition electrovalve

17

Ink addition electrovalve

18

Stirrer motor

19

Viscometer

20

Visc. flow controller

21

Viscometer electrovalve

22

Ink filter

23

Ink transfer electrovalve

24

Head filter

25

Self-closing connections

26

Pressure electrovalve

27

Drain electrovalve

28

Single-jet cannon

29

Twin-jet cannon

30

Recovery gutter

31

Fan

Содержание Markem Imaje 9040

Страница 1: ......

Страница 10: ...A36951 C doc 11 236 Général ...

Страница 11: ...Général A36951 C doc 12 236 ...

Страница 17: ...A36951 C doc 18 236 ...

Страница 18: ...Description of the printer ...

Страница 19: ...Description of the printer ...

Страница 27: ...A36951 C doc 28 236 ...

Страница 28: ...A36951 C doc 29 236 Description of operator interface ...

Страница 29: ...Description of operator interface A36951 C doc 30 236 ...

Страница 42: ...A36951 C doc 43 236 Daily operation ...

Страница 43: ...Daily operation A36951 C doc 44 236 ...

Страница 56: ...A36951 C doc 57 236 Editing a message ...

Страница 57: ...Editing a message ...

Страница 110: ...A36951 C doc 111 236 Servicing 9040 9040 IP65 9040S ...

Страница 111: ...Servicing 9040 9040 IP65 9040S A36951 C doc 112 236 ...

Страница 124: ...A36951 C doc 125 236 Servicing 9040 Contrast ...

Страница 125: ...Servicing 9040 Contrast A36951 C doc 126 236 ...

Страница 135: ...A36951 C doc 136 236 ...

Страница 136: ...A36951 C doc 137 236 Maintenance ...

Страница 137: ...Maintenance A36951 C doc 138 236 ...

Страница 167: ...A36951 C doc 168 236 ...

Страница 168: ...Alarms and faults ...

Страница 169: ...Alarms and faults ...

Страница 182: ...A36951 C doc 183 236 Installation and configuration ...

Страница 183: ...Installation and configuration A36951 C doc 184 236 ...

Страница 194: ...A36951 C doc 195 236 External communications ...

Страница 195: ...External communications A36951 C doc 196 236 ...

Страница 213: ...A36951 C doc 214 236 ...

Страница 214: ... C Technical Specifications ...

Страница 215: ...Technical Specifications C ...

Страница 226: ...A36951 C doc 227 236 Consumables ...

Страница 227: ...Consumables A36951 C doc 228 236 ...

Страница 233: ...A36951 C doc 234 236 ...