MAN05MGO5

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

49

s4YPICALMAINTENANCEACTIVITIES

•electricaladjustmentofsafetydevices,calibrations,andtests(annualloadtest)

•normalmaintenanceworkaftersubstitutionofcomplexand/orcriticalelectricalcomponentryinorderto

maintain safety levels (lifting limit switch, motors, B.T. switchboard)

•repairofelectricalunitsafterextramaintenanceworkhasbeencarriedout(repairoftheelectricmotors

with partial replacement, replacement of limit switches with variation in position, etc.)

s4ECHNICALKNOWLEDGEREQUIRED

•verygoodknowledgeofelectricalsystemsandinstallationsonindustrialliftingandhandlingequipment

•

specific knowledge of the electrical componentry and of the safety devices used in the hoist (limit switches,

brakes, overload switch, etc.)

• experienceofthetechniquesusedinelectricalchecksandadjustments(abilitytoaltertheoriginal

diagrams to make improvements on: limit switches, push-button panel, control consoles, cables, etc.)

•knowledgeofthetechniquesformechanicalchecksandadjustments(weartesting,testperformance

of mechanical components, adjustment of mechanical stops, test noise level, etc.)

•specificcompetenceinthemethodsofmeasurementandtestingtodeterminetheactualstateof

the conditions of the hoist (tests of the efficiency and reliability of the electrical equipment)

•specificcompetenceintrouble-shootingmethodsinalltypesofbreakdownandevaluationofthe

results on the command and control electrical equipment of lifting machines

•

capacity to manage the measures necessary to put the jib crane and the hoist back into action and performance

•abilitytowriteamaintenanceinterventionreport

s1UALIFICATIONREQUIRED

•Completetrainingofanindustrialelectricaltechnicianhavingaspecialisationinandspecificexperience

of electrical apparatus of lifting and handling systems.

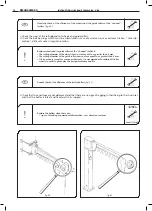

1. If performed correctly maintenance work guarantees the safety of jib crane operators and reduces downtime

to a minimum after a breakdown.

2. Repairs carried out opportunely prevent further deterioration of the crane and its components.

3. Use original spare parts and products.

4. To prepare the crane for maintenance work the following rules must be followed:

•

The staff appointed to do the ordinary or extraordinary maintenance work must have read and understood

well all the instructions contained in this chapter and in chapter 3.

•Extraordinarymaintenanceworkmustonlybecarriedoutbyauthorised,qualifiedstaff,trainedforthe

job.

Electrical technicians

Special recommendations regarding maintenance:

ForproblemswhichmaycomeaboutortoordersparepartscontacttheDONATISOLLEVAMENTI

S.r.l. Technical Assistance Service.

Electromechanical technician:

He is a highly specialised and specifically trained operator, whose professional profile

combinesandsynthesizesnotonlytheabilitiesandknowledgetypicaloftheelectrical

technician, but also those of the mechanical technician.

Maintenance work must be carried out, when possible, while the crane is not connected to the power

supply and in safe conditions, using suitable tools and adequate personal protection devices, in

accordancewiththeregulationsinforce,andaffixingasignwiththewarning:“MAINTENANCE

WORKINPROGRESS”.

KMAN05MG05