10

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

MAN05MGO5

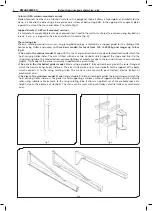

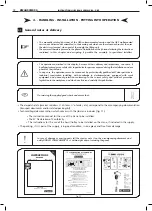

46ERSIONCANTILEVERVERSION

$IMENSIONS-AND.FORWALLMOUNTEDJIBCRANESSEECORRESPONDINGHEIGHTSRELATIVETOCOLUMNMOUNTEDJIBCRANES

Wall-mounted jib crane - Rotation 250°

#OLUMNMOUNTEDJIBCRANE2OTATIONª

,IFTING

capacity

2 A R

3 A R

4 B S

5 B S

125

kg

m

S

Arm

T01A20 170

248

644

200

594

150

15

63

T01A30 170

248

644

200

594

150

15

79

T01B40 170

288

644

200

594

150

15

125

T01B50 170

288

644

200

594

150

15

147

A

Overall dimensions (mm)

Type

GBP series wall-mounted jib cranes – T version

W

eight

of

crane

B

C

D

E

F

Ø

kg

4 A R

5 A R

T01A40 170

248

644

200

594

150

15

95

T01A50 170

248

644

200

594

150

15

111

3 5 T30R40 2800 228

190

655

160

12 148 18.2

3 5 T30R50 2800 228

190

715

160

12 164 18.2

6

F Z

1600

T03F67 255

590

1240

300

1160

220

34

610

190

1270

450

2

E V

3

E V

4

F Z

5

F Z

2000

T03E20 255

499

1240

300

1160 220

34

267

T03E30 255

499

1240

300

1160 220

34

324

T03F40 255

540

1240

300

1160 220

34

400

T03F50 255

590

1240

300

1160 220

34

535

4 6 T40V20 3580 443

210

900

360

20 564 64

4 6 T40V30 3580 443

210

960

360

20 621 64

4 6 T40Z40 3540 513

210

1070

400

20 780 75.2

210

1220

450

3 5 T30R20 2800 228

190

595

160

12 116 18.2

3 5 T30R30 2800 228

190

655

160

12 132 18.2

3 5 T30S40 2760 274

190

725

200

12 200 22.8

3 5 T30S50 2760 274

190

785

200

12 222 22.8

2 B S

3 B S

4 C T

5 C T

6 D U

6 E V

7 E V

250

T01B20 170

288

644

200

594

150

15

81

T01B30 170

288

644

200

594

150

15

103

T02C40 210

346

930

250

870

190

22

195

T02C50 210

346

930

250

870

190

22

226

T02D62 210

406

930

250

870

190

22

340

T03E62 255

500

1240

300

1160

220

34

410

T03E72 255

500

1240

300

1160

220

34

555

3 5 T30S20 2760 274

190

665

200

12 156 22.8

3 5 T30S30 2760 274

190

725

200

12 178 22.8

3.5 5.5 T35T40 3212 323

190

800

240

17 320 35

3.5 5.5 T35T50 3212 323

190

860

240

17 351 35

190

1000

300

4 6 T40V62 3640 443

190

1065

300

20 705 64

4 6 T40V72 3580 443

190

1135

360

20 852 64

2 C T

3 C T

4 D U

5 D U

6 E V

6 F Z

7 E V

7 F Z

500

T02C20 210

346

930

250

870

190

22

134

T02C30 210

346

930

250

870

190

22

165

T02D40 210

406

930

250

870

190

22

256

T02D50 210

406

930

250

870

190

22

298

T03E65 255

500

1240

300

1160

220

34

482

T03E75 255

540

1240

300

1160

220

34

596

3.5 5.5 T35T20 3212 323

190

740

240

17 260 35

3.5 5.5 T35T30 3212 323

190

800

240

17 290 35

3.5 5.5 T35U40 3152 386

190

880

300

17 430 43.5

3.5 5.5 T35U50 3152 386

190

940

300

17 472 43.5

4 5 T40V65 3580 443

190

1140

360

20 779 64

4 6 T40Z62 3580 513

190

1140

360

20 864 75.2

4 4 T40V75 3540 443

190

1270

400

20 893 64

4 6 T40Z72 3540 513

190

1270

400

20 978 75.2

2

D U

3

D U

4

E V

5

E V

6

F Z

7

F Z

1000

T02D20 210

406

930

250

870 190

22

172

T02D30 210

406

930

250

870 190

22

214

T03E40 255

499

1240

300

1160 220

34

381

T03E50 255

499

1240

300

1160 220

34

438

T03F65 255

540

1240

300

1160 220

34

530

T03F75 255

590

1240

300

1160

220

34

688

3.5 5.5 T35U20 3152 386

190

820

300

17 346 43.5

3.5 5.5 T35U30 3152 386

190

880

300

17 388 43.5

4 6 T40V40 3580 443

190

945

360

20 678 64

4 6 T40V50 3580 443

190

1005 360

20 735 64

4 4 T40Z65 3540 513

190

1190 400

20 912 75.2

190

1270 450

Type

Overall dimensions

Weight

GBA series column-mounted jib cranes – T version

Column

by

m

Crane

Under

beam

h

G

M

N

T

(IPE)

6

kg

kg

Size

of

jib

crane

Bracket

Column

H

m

T

otal

height

base

max.

63

KMAN05MG05

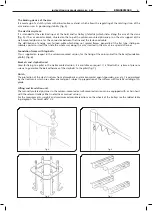

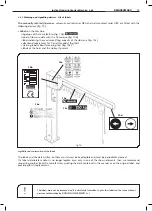

GBP/GBA SERIES JIB CRANES – T VERSION –

CANTILEVER VERSION

LIFTING

CAPACITY

ARM

SIZE OF

JIB CRANE

GBP SERIES WALL-MOUNTED JIB CRANES - T VERSION

GBA SERIES COLUMN-MOUNTED CRANE - VERSION T

S

TYPE

OVERALL DIMENSIONS (mm)

WEIGHT JIB CRANE

HEIGHT

TYPE

OVERALL DIMENSIONS (mm)

WEIGHT

BRA

CKET

COLUMN

A

B

C

D

E

F

Ø

H

m

UNDER

BEAM

JIB

CRANE

COLUMN

BY m

kg

m

kg

BASE MAX.

h

G

M

N

T

(IPE)

Δ

kg

kg

63

4

A

R

T01A40 170 248 644 200 594 150 15

95

3

5

T30R40

2800 228 190 655 160 12

148

18.2

5

A

R

T01A50 170 248 644 200 594 150 15

111

3

5

T30R50

2800 228 190 715 160 12

164

18.2

125

2

A

R

T01A20 170 248 644 200 594 150 15

63

3

5

T30R20

2800 228 190 595 160 12

116

18.2

3

A

R

T01A30 170 248 644 200 594 150 15

79

3

5

T30R30

2800 228 190 655 160 12

132

18.2

4

B

S

T01B40 170 288 644 200 594 150 15

125

3

5

T30S40

2760 274 190 725 200 12

200

22.8

5

B

S

T01B50 170 288 644 200 594 150 15

147

3

5

T30S50

2760 274 190 785 200 12

222

22.8

250

2

B

S

T01B20 170 288 644 200 594 150 15

81

3

5

T30S20

2760 274 190 665 200 12

156

22.8

3

B

S

T01B30 170 288 644 200 594 150 15

103

3

5

T30S30

2760 274 190 725 200 12

178

22.8

4

C

T

T02C40 210 346 930 250 870 190 22

195

3.5

5.5 T35T40

3212 323 190 800 240 17

320

35

5

C

T

T02C50 210 346 930 250 870 190 22

226

3.5

5.5 T35T50

3212 323 190 860 240 17

351

35

6

D

U

T02D62 210 406 930 250 870 190 22

340

190 1000 300

6

E

V

T03E62 255 500 1240 300 1160 220 34

410

4

6

T40V62

3640 443 190 1065 300 20

705

64

7

E

V

T03E72 255 500 1240 300 1160 220 34

555

4

6

T40V72

3580 443 190 1135 360 20

852

64

500

2

C

T

T02C20 210 346 930 250 870 190 22

134

3.5

5.5 T35T20

3212 323 190 740 240 17

260

35

3

C

T

T02C30 210 346 930 250 870 190 22

165

3.5

5.5 T35T30

3212 323 190 800 240 17

290

35

4

D

U

T02D40 210 406 930 250 870 190 22

256

3.5

5.5 T35U40 3152 386 190 880 300 17

430

43.5

5

D

U

T02D50 210 406 930 250 870 190 22

298

3.5

5.5 T35U50 3152 386 190 940 300 17

472

43.5

6

E

V

T03E65 255 500 1240 300 1160 220 34

482

4

5

T40V65

3580 443 190 1140 360 20

779

64

6

F

Z

4

6

T40Z62

3580 513 190 1140 360 20

864

75.2

7

E

V

T03E75 255 540 1240 300 1160 220 34

596

4

4

T40V75

3540 443 190 1270 400 20

893

64

7

F

Z

4

6

T40Z72

3540 513 190 1270 400 20

978

75.2

1000

2

D

U

T02D20 210 406 930 250 870 190 22

172

3.5

5.5 T35U20 3152 386 190 820 300 17

346

43.5

3

D

U

T02D30 210 406 930 250 870 190 22

214

3.5

5.5 T35U30 3152 386 190 880 300 17

388

43.5

4

E

V

T03E40 255 499 1240 300 1160 220 34

381

4

6

T40V40

3580 443 190 945 360 20

678

64

5

E

V

T03E50 255 499 1240 300 1160 220 34

438

4

6

T40V50

3580 443 190 1005 360 20

735

64

6

F

Z

T03F65 255 540 1240 300 1160 220 34

530

4

4

T40Z65

3540 513 190 1190 400 20

912

75.2

7

F

Z

T03F75 255 590 1240 300 1160 220 34

688

190 1270 450

1600

6

F

Z

T03F67 255 590 1240 300 1160 220 34

610

190 1270 450

2000

2

E

V

T03E20 255 499 1240 300 1160 220 34

267

4

6

T40V20

3580 443 210 900 360 20

564

64

3

E

V

T03E30 255 499 1240 300 1160 220 34

324

4

6

T40V30

3580 443 210 960 360 20

621

64

4

F

Z

T03F40 255 540 1240 300 1160 220 34

400

4

6

T40Z40

3540 513 210 1070 400 20

780

75.2

5

F

Z

T03F50 255 590 1240 300 1160 220 34

535

210 1220 450

Heights M* and N* for wall-mounted jib cranes. See corresponding heights relative to column-mounted jib cranes.

Wall-mounted jib crane - Rotation 250°

Column-mounted jib crane - Rotation 290°